Yes, nanomaterials from Mars! A December 21, 2023 news item on Nanowerk makes the proposition, Note: A link has been removed,

Researchers at the University of Sussex have discovered the transformative potential of Martian nanomaterials, potentially opening the door to sustainable habitation on the red planet. They published their findings in (“Quasi–1D Anhydrite Nanobelts from the Sustainable Liquid Exfoliation of Terrestrial Gypsum for Future Martian-Based Electronics”).

Using resources and techniques currently applied on the International Space Station [ISS] and by NASA [US National Aeronautics and Space Administration], Dr Conor Boland, a Lecturer in Materials Physics at the University of Sussex, led a research group that investigated the potential of nanomaterials – incredibly tiny components thousands of times smaller than a human hair – for clean energy production and building materials on Mars.

Taking what was considered a waste product by NASA and applying only sustainable production methods, including water-based chemistry and low-energy processes, the researchers have successfully identified electrical properties within gypsum nanomaterials – opening the door to potential clean energy and sustainable technology production on Mars.

…

A December 21, 2023 University of Sussex press release (also on EurekAlert) by Stephanie Allen, which originated the news item, features the lead researcher’s hopes for the discovery, Note: A link has been removed,

Dr Conor Boland, said:

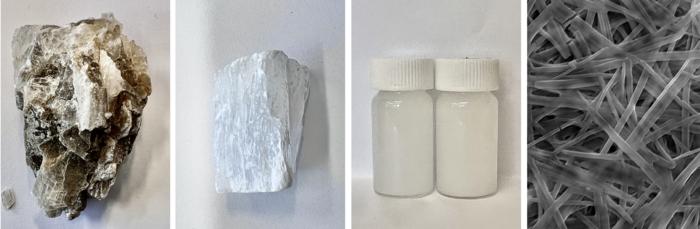

“This study shows that the potential is quite literally out of this world for nanomaterials. Our study builds off recent research performed by NASA and takes what was considered waste, essentially lumps of rock, and turns it into transformative nanomaterials for a range of applications from creating clean hydrogen fuel to developing an electronic device similar to a transistor, to creating an additive to textiles to increase their robustness.

“This opens avenues for sustainable technology – and building – on Mars but also highlights the broader potential for eco-friendly breakthroughs here on Earth.”

To make the breakthrough the researchers used NASA’s innovative method for extracting water from Martian gypsum, which is dehydrated by the agency to get water for human consumption. This produces a byproduct called anhydrite—considered waste material by NASA, but now shown to be hugely valuable.

The Sussex researchers processed anhydrite into nanobelts – essentially tagliatelle-shaped materials – demonstrating their potential to provide clean energy and sustainable electronics. Furthermore, at every step of their process, water could be continuously collected and recycled.

Dr Boland added:

“We are optimistic of the feasibility of this process on Mars, as it requires only naturally occurring materials – everything we used could, in theory, be replicated on the red planet. Arguably this is the most important goal in making the Martian colony sustainable from the outset.”

While full-scale electronics production may be impractical on Mars due to the lack of clean rooms and sterile conditions, the anhydrite nanobelts hold promise for clean energy production on Earth, and could, later down the line, still have a profound effect on sustainable energy production on Mars.

Here’s what a Martian nanomaterial looks like,

Here’s a link to and a citation for the paper,

Quasi–1D Anhydrite Nanobelts from the Sustainable Liquid Exfoliation of Terrestrial Gypsum for Future Martian-Based Electronics by Cencen Wei, Abhijit Roy, Adel K. A. Aljarid, Yi Hu, S. Mark Roe, Dimitrios G. Papageorgiou, Raul Arenal, Conor S. Boland. Advanced Functional Materials DOI: https://doi.org/10.1002/adfm.202310600 First published: 14 December 2023

This paper is open access.

![[downloaded from http://pubs.acs.org/doi/full/10.1021/nn503454h]](http://www.frogheart.ca/wp-content/uploads/2014/08/GrapheneRuberbands-300x108.gif)