This research into using waste products from microbreweries comes from Québec, from a June 22, 2022 news item on ScienceDaily,

For a few years now, spent grain, the cereal residue from breweries, has been reused in animal feed. From now on, this material could also be used in nanotechnology! Professor Federico Rosei’s team at the Institut national de la recherche scientifique (INRS) has shown that microbrewery waste can be used as a carbon source to synthesize quantum dots. The work, done in collaboration with Claudiane Ouellet-Plamondon of the École de technologie supérieure (ÉTS), was published in the Royal Society of Chemistry’s journal RSC Advances

…

A June 22, 2022 Institut national de la recherche scientifique (INRS) news release (also on EurekAlert), which originated the news item, explains what quantum dots have to do with wastage from beer (Note: Links have been removed),

Often considered as “artificial atoms”, quantum dots are used in the transmission of light. With a range of interesting physicochemical properties, this type of nanotechnology has been successfully used as a sensor in biomedicine or as LEDs in next generation displays. But there is a drawback. Current quantum dots are produced with heavy and toxic metals like cadmium. Carbon is an interesting alternative, both for its biocompatibility and its accessibility.

An eco-responsible approach

The choice of brewery waste as a source material came from Daniele Benetti, a postdoctoral fellow at INRS, and Aurel Thibaut Nkeumaleu, the master’s student at ÉTS who conducted the work. Basically, they wanted to carry out various experiments using accessible materials. This is how the scientists came to collaborate with the Brasseurs de Montréal to obtain their cereal residues.

“The use of spent grain highlights both an eco-responsible approach to waste management and an alternative raw material for the synthesis of carbon quantum dots, from a circular economy perspective,” says Professor Rosei.

The advantage of using brewery waste as a source of carbon quantum dots is that it is naturally enriched with nitrogen and phosphorus. This avoids the need for pure chemicals.

“This research was a lot of fun, lighting up what we can do with the beer by-products,” says Claudiane Ouellet-Plamondon, Canada Research Chair in Sustainable Multifunctional Construction Materials at ÉTS. “Moreover, ÉTS is located on the site of the former Dow brewery, one of the main breweries in Quebec until the 1960s. So there is a historical and heritage link to this work.”

An accessible method

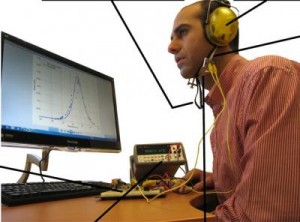

In addition to using biobased material, the research team wanted to show that it was possible to produce carbon quantum dots with common means. The scientists used a domestic microwave oven to carbonize the spent grain, resulting in a black powder. It was then mixed with distilled water and put back into the microwave oven. A passage in the centrifuge and advanced filtration allowed to obtain the quantum dots. Their finished product was able to detect and quantify heavy metals, as well as other contaminants that affect water quality, the environment and health.

The next steps will be to characterize these carbon quantum dots from brewery waste, beyond proof of concept. The research team is convinced that this nanotechnology has the potential to become sophisticated detection sensors for various aqueous solutions, even in living cells.

About the study

The paper “Brewery spent grain derived carbon dots for metal sensing,” by Aurel Thibaut Nkeumaleu, Daniele Benetti, Imane Haddadou, Michael Di Mare, Claudiane Ouellet-Plamondon, and Federico Rosei, was published on April 14, 2022, in the Royal Society of Chemistry journal RSC Advances. The study was supported by the Natural Sciences and Engineering Research Council of Canada (NSERC), the Quebec Centre for Advanced Materials (QCAM) and the Canada Research Chairs.

About INRS

INRS is a university dedicated exclusively to graduate level research and training. Since its creation in 1969, INRS has played an active role in Québec’s economic, social, and cultural development and is ranked first for research intensity in Québec. INRS is made up of four interdisciplinary research and training centres in Québec City, Montréal, Laval, and Varennes, with expertise in strategic sectors: Eau Terre Environnement, Énergie Matériaux Télécommunications, Urbanisation Culture Société, and Armand-Frappier Santé Biotechnologie. The INRS community includes more than 1,500 students, postdoctoral fellows, faculty members, and staff.

Here’s a link to and a citation for the paper,

Brewery spent grain derived carbon dots for metal sensing by Aurel Thibaut Nkeumaleu, Daniele Benetti, Imane Haddadou, Michael Di Mare, Claudiane M. Ouellet-Plamondon and Federico Rosei. RSC Adv., 2022,12, 11621-11627 DOI: https://doi.org/10.1039/D2RA00048B First published: 14 Apr 2022

This paper is open access.