Kudos to the writer for giving a dull topic, supercapacitors and electric cars, a jolt of life. From a July 24, 2014 news item on ScienceDaily,

Innovative nano-material based supercapacitors are set to bring mass market appeal a good step closer to the lukewarm public interest in Germany. [emphasis mine] This movement is currently being motivated by the advancements in the state-of-the-art of this device.

A July 1, 2014 Fraunhofer-Gesellschaft press release (also on EurekAlert), which originated the news item and, sadly, did not reveal the writer’s name, goes on in this refreshing fashion,

Electric cars are very much welcomed in Norway and they are a common sight on the roads of the Scandinavian country – so much so that electric cars topped the list of new vehicle registrations for the second time. This poses a stark contrast to the situation in Germany, where electric vehicles claim only a small portion of the market. Of the 43 million cars on the roads in Germany, only a mere 8000 are electric powered. The main factors discouraging motorists in Germany from switching to electric vehicles are the high investments cost, their short driving ranges and the lack of charging stations. Another major obstacle en route to the mass acceptance of electric cars is the charging time involved. The minutes involved in refueling conventional cars are so many folds shorter that it makes the situation almost incomparable. However, the charging durations could be dramatically shortened with the inclusion of supercapacitors. These alternative energy storage devices are fast charging and can therefore better support the use of economical energy in electric cars. Taking traditional gasoline-powered vehicles for instance, the action of braking converts the kinetic energy into heat which is dissipated and unused. Per contra, generators on electric vehicles are able to tap into the kinetic energy by converting it into electricity for further usage. This electricity often comes in jolts and requires storage devices that can withstand high amount of energy input within a short period of time. In this example, supercapacitors with their capability in capturing and storing this converted energy in an instant fits in the picture wholly. Unlike batteries that offer limited charging/discharging rates, supercapacitors require only seconds to charge and can feed the electric power back into the air-conditioning systems, defogger, radio, etc. as required.

So, the Norwegians have embraced electric cars while the Germans have remained reluctant. The writer offers a clear explanation of supercapacitors and mentions a solution for improving the electric vehicle acceptance rate in Germany (from the press release)

Rapid energy storage devices are distinguished by their energy and power density characteristics – in other words, the amount of electrical energy the device can deliver with respect to its mass and within a given period of time. Supercapacitors are known to possess high power density, whereby large amounts of electrical energy can be provided or captured within short durations, albeit at a short-coming of low energy density. The amount of energy in which supercapacitors are able to store is generally about 10% that of electrochemical batteries (when the two devices of same weight are being compared). This is precisely where the challenge lies and what the “ElectroGraph” project is attempting to address.

ElectroGraph is a project supported by the EU and its consortium consists of ten partners from both research institutes and industries. One of the main tasks of this project is to develop new types of supercapacitors with significantly improved energy storage capacities. As the project is approaches its closing phase in June, the project coordinator at Fraunhofer Institute for Manufacturing Engineering and Automation IPA in Stuttgart, Carsten Glanz explained the concept and approach taken en route to its successful conclusion: “during the storage process, the electrical energy is stored as charged particles attached on the electrode material.” “So to store more energy efficiently, we designed light weight electrodes with larger, usable surfaces.”

Next, the ‘nano’ aspect (graphene) of this particular project is explained,

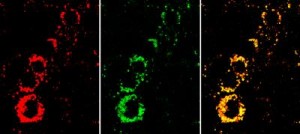

In numerous tests, the researcher and his team investigated the nano-material graphene, whose extremely high specific surface area of up to 2,600 m2/g and high electrical conductivity practically cries out for use as an electrode material. It consists of an ultrathin monolayer lattice made of carbon atoms. When used as an electrode material, it greatly increases the surface area with the same amount of material. From this aspect, graphene is showing its potential in replacing activated carbon – the material that has been used in commercial supercapacitors to date – which has a specific surface area between 1000 and 1800 m2/g.

“The space between the electrodes is filled with a liquid electrolyte,” revealed Glanz. “We use ionic liquids for this purpose. Graphene-based electrodes together with ionic liquid electrolytes present an ideal material combination where we can operate at higher voltages.” “By arranging the graphene layers in a manner that there is a gap between the individual layers, the researchers were able to establish a manufacturing method that efficiently uses the intrinsic surface area available of this nano-material. This prevents the individual graphene layers from restacking into graphite, which would reduce the storage surface and consequently the amount of energy storage capacity. “Our electrodes have already surpassed commercially available one by 75 percent in terms of storage capacity,” emphasizes the engineer. “I imagine that the cars of the future will have a battery connected to many capacitors spread throughout the vehicle, which will take over energy supply during high-power demand phases during acceleration for example and ramming up of the air-conditioning system. These capacitors will ease the burden on the battery and cover voltage peaks when starting the car. As a result, the size of massive batteries can be reduced.”

Whether this effort has already been or, at some time in the future, will be demonstrated is not entirely clear to me,

In order to present the new technology, the ElectroGraph consortium developed a demonstrator consisting of supercapacitors installed in an automobile side-view mirror and charged by a solar cell in an energetically self-sufficient system. The demonstrator will be unveiled at the end of May [2015?] during the dissemination workshop at Fraunhofer IPA.

I imagine improved supercapacitors will be prove to be an enticement for more than one reluctant electric car purchaser no matter where they reside.