A July 16, 2020 news item on Nanowerk announces some work from Rutgers University (New Jersey, US) where carbon dioxide could one day be converted into fuel or perhaps be used in quantum computers,

Imagine tiny crystals that “blink” like fireflies and can convert carbon dioxide, a key cause of climate change, into fuels.

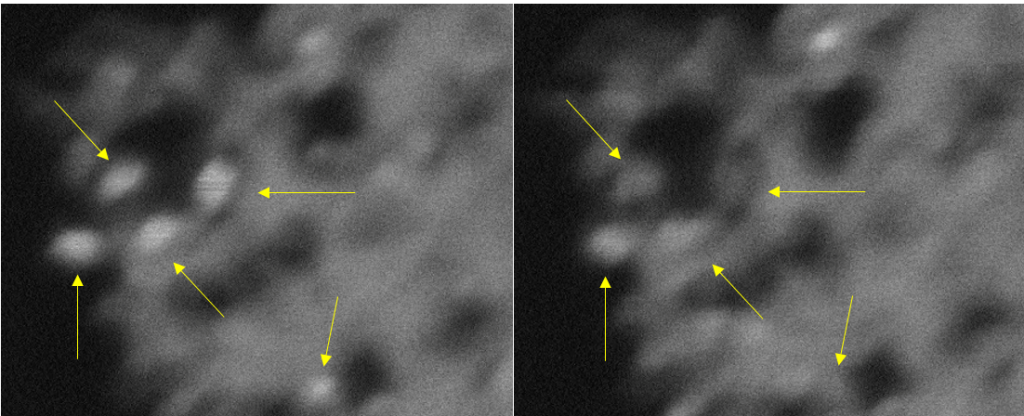

A Rutgers-led team has created ultra-small titanium dioxide crystals that exhibit unusual “blinking” behavior and may help to produce methane and other fuels, according to a study in the journal Angewandte Chemie (“A Blinking Mesoporous TiO2-x Composed of Nanosized Anatase with Unusually Long-Lived Trapped Charge Carriers”).

The crystals, also known as nanoparticles, stay charged for a long time and could benefit efforts to develop quantum computers.

…

I don’t think I have the imagination necessary for this image, which illustrates the work according to the researchers,

A July 16, 2020 Rutgers University news release (also on EurekAlert), which originated the news item, delves further into the topic,

“Our findings are quite important and intriguing in a number of ways, and more research is needed to understand how these exotic crystals work and to fulfill their potential,” said senior author Tewodros (Teddy) Asefa, a professor in the Department of Chemistry and Chemical Biology in the School of Arts and Sciences at Rutgers University-New Brunswick [in New Jersey]. He’s also a professor in the Department of Chemical and Biochemical Engineering in the School of Engineering.

More than 10 million metric tons of titanium dioxide are produced annually, making it one of the most widely used materials, the study notes. It is used in sunscreens, paints, cosmetics and varnishes, for example. It’s also used in the paper and pulp, plastic, fiber, rubber, food, glass and ceramic industries.

The team of scientists and engineers discovered a new way to make extremely small titanium dioxide crystals. While it’s still unclear why the engineered crystals blink and research is ongoing, the “blinking” is believed to arise from single electrons trapped on titanium dioxide nanoparticles. At room temperature, electrons – surprisingly – stay trapped on nanoparticles for tens of seconds before escaping and then become trapped again and again in a continuous cycle.

The crystals, which blink when exposed to a beam of electrons, could be useful for environmental cleanups, sensors, electronic devices and solar cells, and the research team will further explore their capabilities.

Here’s a link to and a citation for the paper,

A Blinking Mesoporous TiO2−x Composed of Nanosized Anatase with Unusually Long‐Lived Trapped Charge Carriers by Dr. Tao Zhang, Dr. Jingxiang Low, Prof. Jiaguo Yu, Dr. Alexei M. Tyryshkin, Dr. Eliška Mikmeková, Prof. Tewodros Asefa. Angewandte Chemie DOI: https://doi.org/10.1002/anie.202005143 First published [online]: 22 May 2020

This paper is behind a paywall.