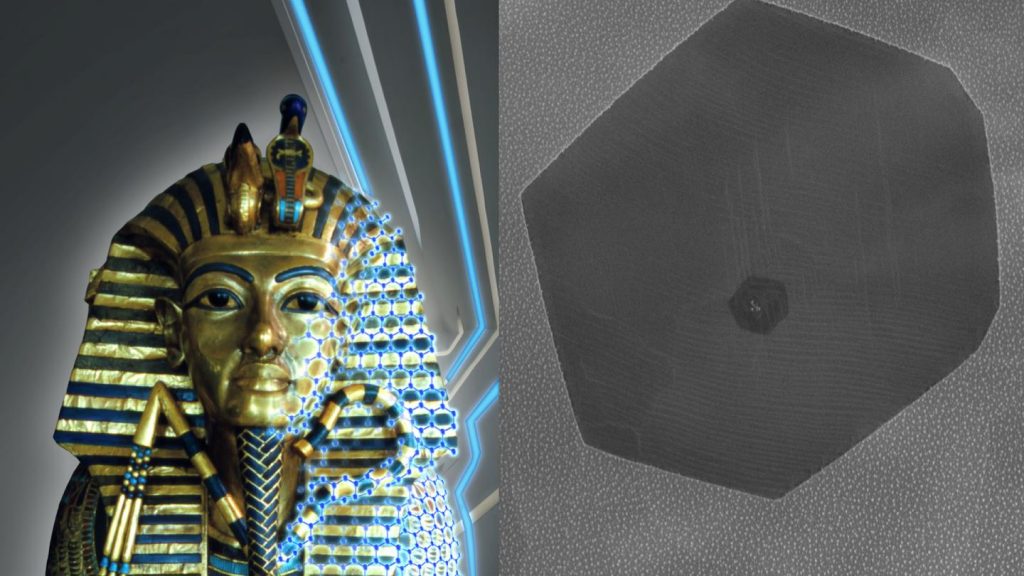

As icons go, Tutankhamun’s middle coffin ranks highly and it’s a great image to use as an example of what might be accomplished with graphene gilding. From a Sept. 10, 2018 news item on Nanowerk,

Gilding is the process of coating intricate artifacts with precious metals. Ancient Egyptians and Chinese coated their sculptures with thin metal films using gilding—and these golden sculptures have resisted corrosion, wear, and environmental degradation for thousands of years. The middle and outer coffins of Tutankhamun, for instance, are gold leaf gilded, as are many other ancient treasures.

In a new study, Illinois’ Sameh Tawfick, from the Department of Mechanical Science & Engineering (MechSE) and the Beckman Institute, inspired by this ancient process, has added a single layer of carbon atoms, known as graphene, on top of metal leaves—doubling the protective quality of gilding against wear and tear.

A Sept. 10, 2018 University of Illinois news release (also on EurekAlert), which originated the news item, offers more details,

Metal leaves, or foils, offer many advantages as a scalable coating material, including their commercial availability in large rolls and their comparatively low price. By bonding a single layer of graphene to the leaves, Tawfick and his team demonstrated unexpected benefits, including enhanced mechanical resistance. Their work presents exciting opportunities for protective coating applications on large structures like buildings or ship hulls, metal surfaces of consumer electronics, and small precious artifacts or jewelry.

“Adding one more layer of graphene atoms onto the palladium made it twice as resistant to indents than the bare leaves alone,” said Tawfick. “It’s also very attractive from a cost perspective. The amount of graphene needed to cover the gilded structures of the Carbide & Carbon Building in Chicago, for example, would be the size of the head of a pin.”

Additionally, the team developed a new technology to grow high-quality graphene directly on the surface of 150 nanometer-thin palladium leaves—in just 30 seconds. Using a process called chemical vapor deposition, in which the metal leaf is processed in a 1,100°C furnace, the bare palladium leaf acts as a catalyst, allowing the gases to react quickly.

“Chemical vapor deposition of graphene requires a very high temperature, which could melt the leaves or cause them to bead up by a process called solid state dewetting,” said Kaihao Zhang, PhD candidate in MechSE and lead author of the study. “The process we developed deposits the graphene quickly enough to avoid high-temperature degradation, it’s scalable, and it produces graphene of very high quality.”

Here’s a link to and a citation for the paper,

Gilding with Graphene: Rapid Chemical Vapor Deposition Synthesis of Graphene on Thin Metal Leaves by Kaihao Zhang, Charalampos Androulidakis, Mingze Chen, Sameh Tawfick. Advanced Functional Materials DOI: https://doi.org/10.1002/adfm.201804068 First published: 06 September 2018

This paper is behind a paywall.

![Image used to illustrate abstract (downloaded from http://pubs.acs.org/doi/abs/10.1021/ar300232e]](http://www.frogheart.ca/wp-content/uploads/2013/07/Gilded-Ring-140x300.gif)