Not all science research and breakthroughs require massive investments of money, sometimes all you need is a home DVD burner as this Feb. 19, 2013 news release on EurekAlert notes,

While the demand for ever-smaller electronic devices has spurred the miniaturization of a variety of technologies, one area has lagged behind in this downsizing revolution: energy-storage units, such as batteries and capacitors.

Now, Richard Kaner, a member of the California NanoSystems Institute at UCLA and a professor of chemistry and biochemistry, and Maher El-Kady, a graduate student in Kaner’s laboratory, may have changed the game.

The UCLA researchers have developed a groundbreaking technique that uses a DVD burner to fabricate micro-scale graphene-based supercapacitors — devices that can charge and discharge a hundred to a thousand times faster than standard batteries. These micro-supercapacitors, made from a one-atom–thick layer of graphitic carbon, can be easily manufactured and readily integrated into small devices such as next-generation pacemakers.

The new cost-effective fabrication method, described in a study published this week in the journal Nature Communications, holds promise for the mass production of these supercapacitors, which have the potential to transform electronics and other fields.

…

“Traditional methods for the fabrication of micro-supercapacitors involve labor-intensive lithographic techniques that have proven difficult for building cost-effective devices, thus limiting their commercial application,” El-Kady said. “Instead, we used a consumer-grade LightScribe DVD burner to produce graphene micro-supercapacitors over large areas at a fraction of the cost of traditional devices. [emphasis mine] Using this technique, we have been able to produce more than 100 micro-supercapacitors on a single disc in less than 30 minutes, using inexpensive materials.”

The University of California at Los Angeles (UCLA) Feb. 19, 2013 news release written by David Malasarn, the origin of the EurekAlert news release, features more information about the process,

The process of miniaturization often relies on flattening technology, making devices thinner and more like a geometric plane that has only two dimensions. In developing their new micro-supercapacitor, Kaner and El-Kady used a two-dimensional sheet of carbon, known as graphene, which only has the thickness of a single atom in the third dimension.Kaner and El-Kady took advantage of a new structural design during the fabrication. For any supercapacitor to be effective, two separated electrodes have to be positioned so that the available surface area between them is maximized. This allows the supercapacitor to store a greater charge. A previous design stacked the layers of graphene serving as electrodes, like the slices of bread on a sandwich. While this design was functional, however, it was not compatible with integrated circuits.In their new design, the researchers placed the electrodes side by side using an interdigitated pattern, akin to interwoven fingers. This helped to maximize the accessible surface area available for each of the two electrodes while also reducing the path over which ions in the electrolyte would need to diffuse. As a result, the new supercapacitors have more charge capacity and rate capability than their stacked counterparts.Interestingly, the researchers found that by placing more electrodes per unit area, they boosted the micro-supercapacitor’s ability to store even more charge.Kaner and El-Kady were able to fabricate these intricate supercapacitors using an affordable and scalable technique that they had developed earlier. They glued a layer of plastic onto the surface of a DVD and then coated the plastic with a layer of graphite oxide. Then, they simply inserted the coated disc into a commercially available LightScribe optical drive — traditionally used to label DVDs — and took advantage of the drive’s own laser to create the interdigitated pattern. The laser scribing is so precise that none of the “interwoven fingers” touch each other, which would short-circuit the supercapacitor.“To label discs using LightScribe, the surface of the disc is coated with a reactive dye that changes color on exposure to the laser light. Instead of printing on this specialized coating, our approach is to coat the disc with a film of graphite oxide, which then can be directly printed on,” Kaner said. “We previously found an unusual photo-thermal effect in which graphite oxide absorbs the laser light and is converted into graphene in a similar fashion to the commercial LightScribe process. With the precision of the laser, the drive renders the computer-designed pattern onto the graphite oxide film to produce the desired graphene circuits.”“The process is straightforward, cost-effective and can be done at home,” El-Kady said. “One only needs a DVD burner and graphite oxide dispersion in water, which is commercially available at a moderate cost.”The new micro-supercapacitors are also highly bendable and twistable, making them potentially useful as energy-storage devices in flexible electronics like roll-up displays and TVs, e-paper, and even wearable electronics.

The reference to e-paper and roll-up displays calls to mind work being done at Queen’s University (Kingston, Canada) and Roel Vertegaal’s work on bendable, flexible phones and computers (my Jan. 9, 2013 posting). Could this work on micro-supercapacitors have an impact on that work?

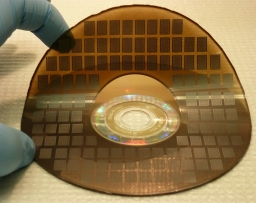

Here’s an image (supplied by UCLA) of the micro-supercapacitors ,

UCLA has also supplied a video of Kaner and El-Kady discussing their work,

Interestingly this video has been supported by GE (General Electric), a company which seems to be doing a great deal to be seen on the internet these days as per my Feb. 11, 2013 posting titled, Visualizing nanotechnology data with Seed Media Group and GE (General Electric).

Getting back to the researchers, they are looking for industry partners as per Malasarn’s news release.