It seems water can play an important role when using nanocatalysts made of gold nanoparticles combined with metal oxides. From a July 27, 2020 news item on ScienceDaily,

Nanocatalysts made of gold nanoparticles dispersed on metal oxides are very promising for the industrial, selective oxidation of compounds, including alcohols, into valuable chemicals. They show high catalytic activity, particularly in aqueous solution. A team of researchers from Ruhr-Universität Bochum (RUB) has been able to explain why: Water molecules play an active role in facilitating the oxygen dissociation needed for the oxidation reaction. The team of Professor Dominik Marx, Chair of Theoretical Chemistry, reports in the high-impact journal ACS Catalysis on 14 July 2020.

…

A July 27, 2020 Ruhr-University Bochum (RUB) press release (also on EurekAlert), which originated the news item, offers more detail,

Rushing for gold

Most industrial oxidation processes involve the use of agents, such as chlorine or organic peroxides, that produce toxic or useless by-products. Instead, using molecular oxygen, O2, and splitting it to obtain the oxygen atoms needed to produce specific products would be a greener and more attractive solution. A promising medium for this approach is the gold/metal oxide (Au/TiO2) system, where the metal oxide titania (TiO2) supports nanoparticles of gold. These nanocatalysts can catalyse the selective oxidation of molecular hydrogen, carbon monoxide and especially alcohols, among others. A crucial step behind all reactions is the dissociation of O2, which comprises a usually high energy barrier. And a crucial unknown in the process is the role of water, since the reactions take place in aqueous solutions.

In a 2018 study, the RUB group of Dominik Marx, Chair of Theoretical Chemistry and Research Area coordinator in the Cluster of Excellence Ruhr Explores Solvation (Resolv), already hinted that water molecules actively participate in the oxidative reaction: They enable a stepwise charge-transfer process that leads to oxygen dissociation in the aqueous phase. Now, the same team reveals that solvation facilitates the activation of molecular oxygen (O2) at the gold/metal oxide (Au/TiO2) nanocatalyst: In fact, water molecules help to decrease the energy barrier for the O2 dissociation. The researchers quantified that the solvent curbs the energy costs by 25 per cent compared to the gas phase. “For the first time, it has been possible to gain insights into the quantitative impact of water on the critical O2 activation reaction for this nanocatalyst – and we also understood why,” says Dominik Marx.

Mind the water molecules

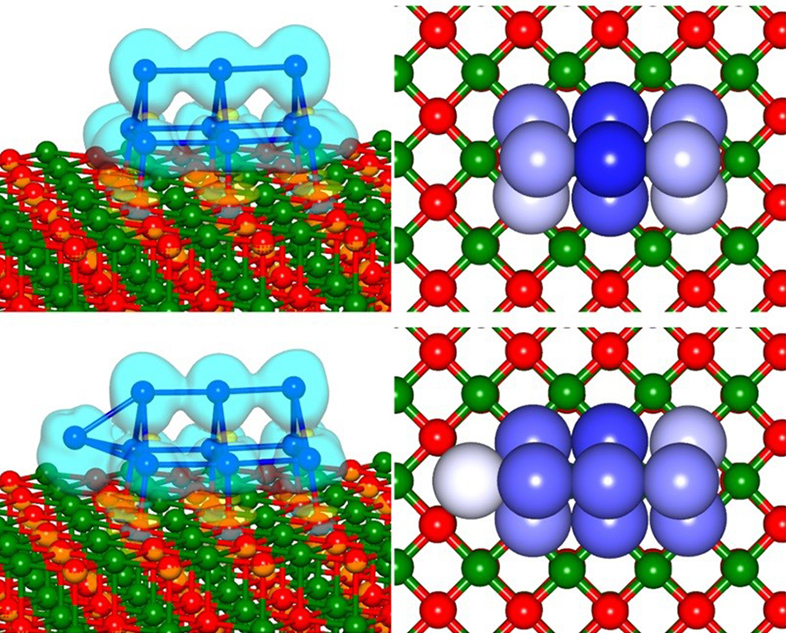

The RUB researchers applied computer simulations, the so-called ab initio molecular dynamics simulations, which explicitly included not only the catalyst but also as many as 80 surrounding water molecules. This was key to gain deep insights into the liquid-phase scenario, which contains water, in direct comparison to the gas phase conditions, where water is absent. “Previous computational work employed significant simplifications or approximations that didn’t account for the true complexity of such a difficult solvent, water,” adds Dr. Niklas Siemer who recently earned his PhD at RUB based on this research.

Scientists simulated the experimental conditions with high temperature and pressure to obtain the free energy profile of O2 in both liquid and gas phase. Finally, they could trace back the mechanistic reason for the solvation effect: Water molecules induce an increase of local electron charge towards oxygen that is anchored at the nanocatalyst perimeter; this in turn leads to the less energetic costs for the dissociation. In the end, say the researchers, it’s all about the unique properties of water: “We found that the polarizability of water and its ability to donate hydrogen bonds are behind oxygen activation,” says Dr. Munoz-Santiburcio. According to the authors, the new computational strategy will help to understand and improve direct oxidation catalysis in water and alcohols.

Here’s a link to and a citation for the paper,

Solvation-Enhanced Oxygen Activation at Gold/Titania Nanocatalysts by Niklas Siemer, Daniel Muñoz-Santiburcio, and Dominik Marx. ACS Catal. 2020, 10, 15, 8530–8534 DOI: https://doi.org/10.1021/acscatal.0c01326 Publication Date: July 14, 2020 Copyright © 2020 American Chemical Society

This paper is behind a paywall.