Earlier this week in a March 30, 2015 post, I was bemoaning the dearth of applications for cellulose nanocrystals (CNC) with concomitant poor prospects for commercialization and problems for producers such as Canada’s CelluForce. Possibly this work at Purdue University (Indiana, US) will help address some of those issues (from a March 31, 2015 news item on Nanowerk),

Cellulose nanocrystals derived from industrial byproducts have been shown to increase the strength of concrete, representing a potential renewable additive to improve the ubiquitous construction material.

The cellulose nanocrystals (CNCs) could be refined from byproducts generated in the paper, bioenergy, agriculture and pulp industries. They are extracted from structures called cellulose microfibrils, which help to give plants and trees their high strength, lightweight and resilience. Now, researchers at Purdue University have demonstrated that the cellulose nanocrystals can increase the tensile strength of concrete by 30 percent.

A March 31, 2015 Purdue University news release by Emil Venere, which originated the news item, further describes the research published in print as of February 2015 (Note: A link has been removed),

One factor limiting the strength and durability of today’s concrete is that not all of the cement particles are hydrated after being mixed, leaving pores and defects that hamper strength and durability.

“So, in essence, we are not using 100 percent of the cement,” Zavattieri [Pablo Zavattieri, an associate professor in the Lyles School of Civil Engineering] said.

However, the researchers have discovered that the cellulose nanocrystals increase the hydration of the concrete mixture, allowing more of it to cure and potentially altering the structure of concrete and strengthening it. As a result, less concrete needs to be used.

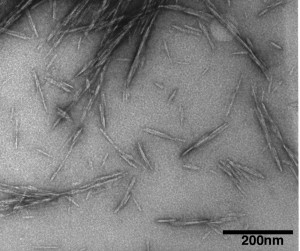

The cellulose nanocrystals are about 3 to 20 nanometers wide by 50-500 nanometers long – or about 1/1,000th the width of a grain of sand – making them too small to study with light microscopes and difficult to measure with laboratory instruments. They come from a variety of biological sources, primarily trees and plants.

The concrete was studied using several analytical and imaging techniques. Because chemical reactions in concrete hardening are exothermic, some of the tests measured the amount of heat released, indicating an increase in hydration of the concrete. The researchers also hypothesized the precise location of the nanocrystals in the cement matrix and learned how they interact with cement particles in both fresh and hardened concrete. The nanocrystals were shown to form little inlets for water to better penetrate the concrete.

The research dovetails with the goals of P3Nano, a public-private partnership supporting development and use of wood-based nanomaterial for a wide-range of commercial products.

“The idea is to support and help Purdue further advance the CNC-Cement technology for full-scale field trials and the potential for commercialization,” Zavattieri said.

The researchers have provided an image,

This transmission electron microscope image shows cellulose nanocrystals, tiny structures derived from renewable sources that might be used to create a new class of biomaterials with many potential applications. The structures have been shown to increase the strength of concrete. (Purdue Life Sciences Microscopy Center)

Here’s a link to and a citation for the paper,

The influence of cellulose nanocrystal additions on the performance of cement paste by Yizheng Cao, Pablo Zavaterri, Jeff Youngblood, Robert Moon, and Jason Weiss. Cement and Concrete Composites, Volume 56, February 2015, Pages 73–83 DOI: 10.1016/j.cemconcomp.2014.11.008 Available online 18 November 2014

The paper is behind a paywall.

One final note, cellulose nanocrystals (CNC) may also be referred to nanocrystalline cellulose (NCC).