I guess if you’re going to use bacteria as part of your gene editing technology (CRISPR [clustered regularly interspaced short palindromic repeats]/Cas9) then, you might half expect the body’s immune system may have developed some defenses. A Jan. 9, 2018 article by Sarah Zhang for The Atlantic provides some insight into what the new research suggests (Note: Links have been removed),

2018 is supposed to be the year of CRISPR in humans. The first U.S. and European clinical trials that test the gene-editing tool’s ability to treat diseases—such as sickle-cell anemia, beta thalassemia, and a type of inherited blindness—are slated to begin this year.

But the year has begun on a cautionary note. On Friday [January 5, 2018], Stanford researchers posted a preprint (which has not been peer reviewed) to the website biorXiv highlighting a potential obstacle to using CRISPR in humans: Many of us may already be immune to it. That’s because CRISPR actually comes from bacteria that often live on or infect humans, and we have built up immunity to the proteins from these bacteria over our lives.

…

Not all CRISPR therapies in humans will be doomed. “We don’t think this is the end of the story. This is the start of the story,” says Porteus [Matthew Porteus, a pediatrician and stem-cell researcher at Stanford]. There are likely ways around the problem of immunity to CRISPR proteins, and many of the early clinical trials appear to be designed around this problem.

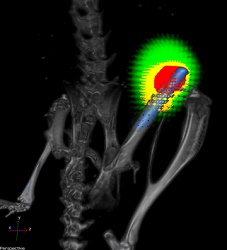

Porteus and his colleagues focused on two versions of Cas9, the bacterial protein mostly commonly used in CRISPR gene editing. One comes from Staphylococcus aureus, which often harmlessly lives on skin but can sometimes causes staph infections, and another from Streptococcus pyogenes, which causes strep throat but can also become “flesh-eating bacteria” when it spreads to other parts of the body. So yeah, you want your immune system to be on guard against these bacteria.

The human immune system has a couple different ways of recognizing foreign proteins, and the team tested for both. First, they looked to see if people have molecules in their blood called antibodies that can specifically bind to Cas9. Among 34 people they tested, 79 percent had antibodies against the staph Cas9 and 65 percent against the strep Cas9.

The Stanford team only tested for preexisting immunity against Cas9, but anytime you inject a large bacterial protein into the human body, it can provoke an immune response. After all, that’s how the immune system learns to fight off bacteria it’s never seen before. (Preexisting immunity can make the response faster and more robust, though.)

…

The danger of the immune system turning on a patient’s body hangs over a lot of research into correcting genes. In the late 1990s and 2000s, research into gene therapy was derailed by the death of 18-year-old Jesse Gelsinger, who died from an immune reaction to the virus used to deliver the corrected gene. This is the worst-case scenario that the CRISPR world hopes to avoid.

Here’s a link to and a citation for the preprint,

Identification of Pre-Existing Adaptive Immunity to Cas9 Proteins in Humans by Carsten Trevor Charlesworth, Priyanka S Deshpande, Daniel P Dever, Beruh Dejene, Natalia Gomez-Ospina, Sruthi Mantri, Mara Pavel-Dinu, Joab Camarena, Kenneth I Weinberg, Matthew H Porteus. bioRxiv posted January 5, 2018 doi: https://doi.org/10.1101/243345

This article is a preprint and has not been peer-reviewed …

This preprint (not yet published paper) is open access and open for feedback.

Meanwhile, the year of CRISPR takes off (from a January 10, 2018 American Chemical Society news release on EurekAlert),

This year could be a defining one for CRISPR, the gene editing technique, which has been hailed as an important breakthrough in laboratory research. That’s because the first company-sponsored clinical studies will be conducted to see if it can help treat diseases in humans, according to an article in Chemical & Engineering News (C&EN), the weekly newsmagazine of the American Chemical Society.

C&EN Assistant Editor Ryan Cross reports that a big push is coming from industry, specifically from three companies that are each partly founded by one of the three inventors of the method. They are zeroing in on the blood diseases called sickle-cell anemia and β-thalassemia, mostly because their precise cause is known. In these diseases, hemoglobin doesn’t function properly, leading to severe health issues in some people. Crispr Therapeutics and Intellia Therapeutics plan to test the technique to boost levels of an alternative version of healthy hemoglobin. Editas Medicine, however, will also use CRISPR to correct mutations in the faulty hemoglobin gene. Labs led by university researchers are also joining the mix, starting or continuing clinical trials with the approach in 2018.

Because CRISPR is being used to cut a cell’s DNA and insert a new sequence, concerns have been raised about the potential for accidents. A cut in the wrong place could mean introducing a new mutation that could be benign — or cancerous. But according to proponents of the method, researchers are conducting extensive computer predictions and in vitro tests to help avoid this outcome.

The January 8, 2018 Chemical and Engineering News (C&EN) open access article by Ryan Cross is here.

Finally, if you are interested in how this affects research as it’s being developed, there’s University of British Columbia researcher Rosie Redfield’s January 16, 2018 posting on RRResearch blog,

Thursday’s [January 11, 2018] post described the hypothesis that bacteria might use gene transfer agent particles to inoculate other cells in the population with fragments of phage DNA, and outlined an experiment to test this. Now I’m realizing that I need to know a lot more about the kind of immunity I should expect to see if this GTA-as-vaccine hypothesis is correct.

That should give you some idea of what I meant by “research as it’s being developed.” Redfield’s blog is not for the mildly interested.

Redfield is well-known internationally as being one of the first to refute research which suggested the existence of an ‘arsenic bacterium’ (see my Dec. 8, 2010 posting: My apologies for arsenic blooper. She’s first mentioned in the second excerpt, second paragraph.) The affair was known online as #arseniclife. There’s a May 27, 2011 essay by Carl Zimmer on Slate titled: The Discovery of Arsenic-Based Twitter: How #arseniclife changed science.