Caption: Novel nanolaser leverages the same color-changing mechanism that a chameleon uses to camouflage its skin. Credit: Egor Kamelev Courtesy: Northwestern University

I wish there was some detail included about how those colo(u)rs were achieved in that photograph. Strangely, Northwestern University (Chicago, Illinois, US) is more interested in describing the technology that chameleons have inspired. A June 20, 2018 news item on ScienceDaily announces the research,

As a chameleon shifts its color from turquoise to pink to orange to green, nature’s design principles are at play. Complex nano-mechanics are quietly and effortlessly working to camouflage the lizard’s skin to match its environment.

Inspired by nature, a Northwestern University team has developed a novel nanolaser that changes colors using the same mechanism as chameleons. The work could open the door for advances in flexible optical displays in smartphones and televisions, wearable photonic devices and ultra-sensitive sensors that measure strain.

A June 20, 2018 Northwestern University news release (also on EurekAlert) by Amanda Morris, which originated the news item, expands on the theme,

“Chameleons can easily change their colors by controlling the spacing among the nanocrystals on their skin, which determines the color we observe,” said Teri W. Odom, Charles E. and Emma H. Morrison Professor of Chemistry in Northwestern’s Weinberg College of Arts and Sciences. “This coloring based on surface structure is chemically stable and robust.”

The research was published online yesterday [June 19, 2018] in the journal Nano Letters. Odom, who is the associate director of Northwestern’s International Institute of Nanotechnology, and George C. Schatz, Charles E. and Emma H. Morrison Professor of Chemistry in Weinberg, served as the paper’s co-corresponding authors.

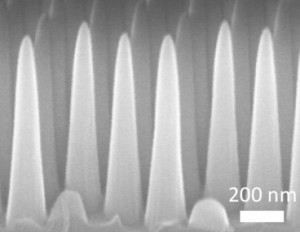

The same way a chameleon controls the spacing of nanocrystals on its skin, the Northwestern team’s laser exploits periodic arrays of metal nanoparticles on a stretchable, polymer matrix. As the matrix either stretches to pull the nanoparticles farther apart or contracts to push them closer together, the wavelength emitted from the laser changes wavelength, which also changes its color.

“Hence, by stretching and releasing the elastomer substrate, we could select the emission color at will,” Odom said.

The resulting laser is robust, tunable, reversible and has a high sensitivity to strain. These properties are critical for applications in responsive optical displays, on-chip photonic circuits and multiplexed optical communication.

Here’s a link to and a citation for the paper,

Stretchable Nanolasing from Hybrid Quadrupole Plasmons by Danqing Wang, Marc R. Bourgeois, Won-Kyu Lee, Ran Li, Dhara Trivedi, Michael P. Knudson, Weijia Wang, George C. Schatz, and Teri W. Odom. Nano Lett., Article ASAP DOI: 10.1021/acs.nanolett.8b01774 Publication Date (Web): June 18, 2018

Copyright © 2018 American Chemical Society

This paper is behind a paywall.