It looks more like a swimming pool with pool toys to me but I imagine that nobody wants to say that they’re sending ‘pool toys’ through your bloodstream. Nanoflowers or flower-shaped nanoparticles sounds nicer.

From a January 10, 2019 news item on Nanowerk,

Washington State University [WSU] researchers have developed a novel way to deliver drugs and therapies into cells at the nanoscale without causing toxic effects that have stymied other such efforts.

The work could someday lead to more effective therapies and diagnostics for cancer and other illnesses.

Led by Yuehe Lin, professor in WSU’s School of Mechanical and Materials Engineering, and Chunlong Chen, senior scientist at the Department of Energy’s Pacific Northwest National Laboratory (PNNL), the research team developed biologically inspired materials at the nanoscale that were able to effectively deliver model therapeutic genes into tumor cells. …

A January 10, 2019 WSU news release (also on EurekAlert) by Tina Hilding, which originated the news item, describes the work in greater detail,

Researchers have been working to develop nanomaterials that can effectively carry therapeutic genes directly into the cells for the treatment of diseases such as cancer. The key issues for gene delivery using nanomaterials are their low delivery efficiency of medicine and potential toxicity.

“To develop nanotechnology for medical purposes, the first thing to consider is toxicity — That is the first concern for doctors,” said Lin.

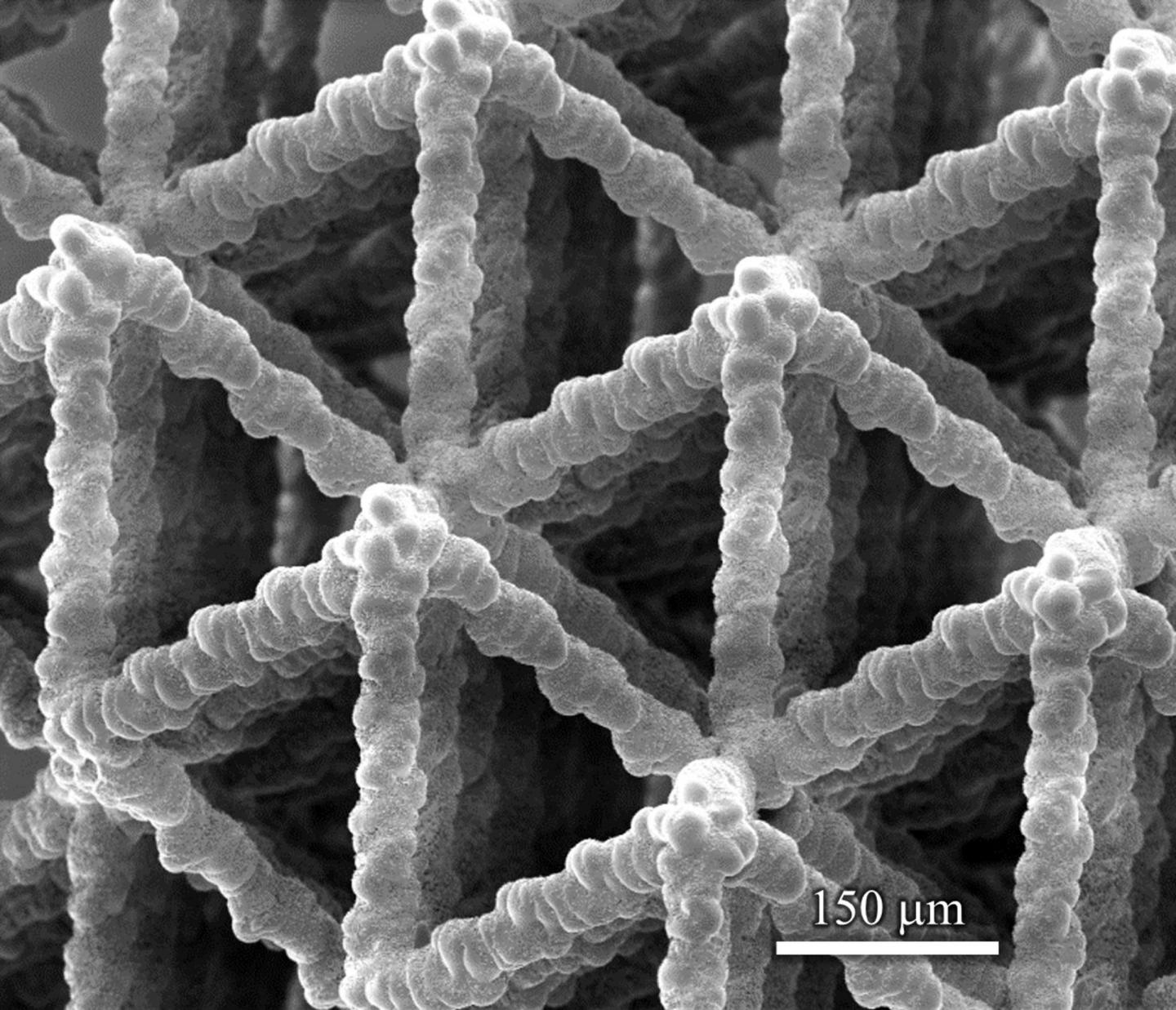

The flower-like particle the WSU and PNNL team developed is about 150 nanometers in size, or about one thousand times smaller than the width of a piece of paper. It is made of sheets of peptoids, which are similar to natural peptides that make up proteins. The peptoids make for a good drug delivery particle because they’re fairly easy to synthesize and, because they’re similar to natural biological materials, work well in biological systems.

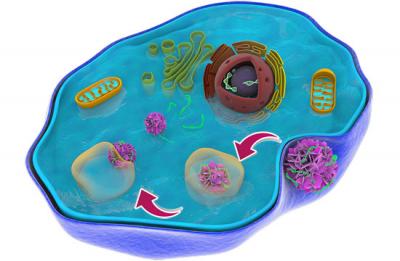

The researchers added fluorescent probes in their peptoid nanoflowers, so they could trace them as they made their way through cells, and they added the element fluorine, which helped the nanoflowers more easily escape from tricky cellular traps that often impede drug delivery.

The flower-like particles loaded with therapeutic genes were able to make their way smoothly out of the predicted cellular trap, enter the heart of the cell, and release their drug there.

“The nanoflowers successfully and rapidly escaped (the cell trap) and exhibited minimal cytotoxicity,” said Lin.

After their initial testing with model drug molecules, the researchers hope to conduct further studies using real medicines.

“This paves a new way for us to develop nanocargoes that can efficiently deliver drug molecules into the cell and offers new opportunities for targeted gene therapies,” he said.

The WSU and PNNL team have filed a patent application for the new technology, and they are seeking industrial partners for further development.

Should you and your company be interested in partnering with the researchers, contact:

- Yuehe Lin, professor, School of Mechanical and Materials Engineering, 509‑335‑8523, yuehe.lin@wsu.edu

- Tina Hilding, communications director, Voiland College of Engineering and Architecture, 509‑335‑5095, thilding@wsu.edu

For those who’d like more information, here’s a link to and a citation for the paper,

Efficient Cytosolic Delivery Using Crystalline Nanoflowers Assembled from Fluorinated Peptoids by Yang Song, Mingming Wang, Suiqiong Li, Haibao Jin, Xiaoli Cai, Dan Du, He Li, Chun‐Long Chen, Yuehe Lin. Small DOI: https://doi.org/10.1002/smll.201803544 First published: 22 November 2018

This paper is behind a paywall.