I have two sea-inspired news bits both of which concern adhesion.

Mussels and titanium implants

A July 8, 2016 news item on ScienceDaily features some mussel-inspired research from Japan into how to make better titanium implants,

Titanium is used medically in applications such as artificial joints and dental implants. While it is strong and is not harmful to tissues, the metal lacks some of the beneficial biological properties of natural tissues such as bones and natural teeth. Now, based on insights from mussels–which are able to attach themselves very tightly to even metallic surfaces due to special proteins found in their byssal threads–scientists from RIKEN have successfully attached a biologically active molecule to a titanium surface, paving the way for implants that can be more biologically beneficial.

A July 11, 2016 RIKEN press release (also on EurekAlert but dated July 8, 2016), which originated the news item, provides more information,

The work began from earlier discoveries that mussels can attach to smooth surfaces so effectively thanks to a protein, L-DOPA, which is known to be able to bind very strongly to smooth surfaces such as rocks, ceramics, or metals (…). Interestingly, the same protein functions in humans as a precursor to dopamine, and is used as a treatment for Parkinson’s disease.

According to Chen Zhang of the RIKEN Nano Medical Engineering Laboratory, the first author of the paper published in Angewandte Chemie, “We thought it would be interesting to try to use various techniques to attach a biologically active protein—in our case we chose insulin-like growth factor-1, a promoter of cell proliferation—to a titanium surface like those used in implants” (…).

Using a combination of recombinant DNA technology and treatment with tyrosinase, they were able to create a hybrid protein that contained active parts of both the growth factor and L-DOPA. Tests showed that the proteins were able to fold normally, and further experiments in cell cultures demonstrated that the IGF-1 was still functioning normally. Thanks to the incorporation of the L-DOPA, the team was able to confirm that the proteins bound strongly to the titanium surface, and remained attached even when the metal was washed with phosphate-buffered saline, a water-based solution. Zhang says, “This is similar to the powerful properties of mussel adhesive, which can remain fixed to metallic materials even underwater.”

According to Yoshihiro Ito, Team Leader of the Emergent Bioengineering Research Team of the RIKEN Center for Emergent Matter Science, “We are very excited by this finding, because the modification process is a universal one that could be used with other proteins. It could allow us to prepare new cell-growth enhancing materials, with potential applications in cell culture systems and regenerative medicine. And it is particularly interesting that this is an example of biomimetics, where nature can teach us new ways to do things. The mussel has given us insights that could be used to allow us to live healthier lives.”

The work was done by RIKEN researchers in collaboration with Professor Peibiao Zhang of the Changchun Institute of Applied Chemistry, Chinese Academy of Sciences, and Professor Yi Wang of the School of Pharmaceutical Sciences, Jilin University. The work was partially supported by the Japan Society for the Promotion of Science KAKENHI (Grant Number 15H01810 and 22220009), CAS-JSPS joint fund (GJHZ1519), and RIKEN MOST joint project.

Here’s a link to and a citation for the paper,

A Bioorthogonal Approach for the Preparation of a Titanium-Binding Insulin-like Growth-Factor-1 Derivative by using Tyrosinase by Chen Zhang, Hideyuki Miyatake, Yu Wang, Takehiko Inaba, Yi Wang, Peibiao Zhang, and Prof. Yoshihiro Ito. Angewandte Chemie International Edition DOI: 10.1002/anie.201603155 Version of Record online: 6 JUL 2016

© 2016 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

This paper is behind a paywall.

Octopuses/octopi/octopodes and adhesive panels

Before launching into the science part of this news bit, here’s some grammar (from the Octopus Wikipedia entry; Note: Links have been removed),

The standard pluralized form of “octopus” in the English language is “octopuses” /ˈɒktəpʊsɪz/,[10] although the Ancient Greek plural “octopodes” /ɒkˈtɒpədiːz/, has also been used historically.[9] The alternative plural “octopi” — which misguidedly assumes it is a Latin “-us”-word — is considered grammatically incorrect.[11][12][13][14] It is nevertheless used enough to make it notable, and was formally acknowledged by the descriptivist Merriam-Webster 11th Collegiate Dictionary and Webster’s New World College Dictionary. The Oxford English Dictionary (2008 Draft Revision)[15] lists “octopuses”, “octopi”, and “octopodes”, in that order, labelling “octopodes” as rare and noting that “octopi” derives from the apprehension that octōpus comes from Latin.[16] In contrast, New Oxford American Dictionary (3rd Edition 2010) lists “octopuses” as the only acceptable pluralization, with a usage note indicating “octopodes” as being still occasionally used but “octopi” as being incorrect.[17]

Now the news. A July 12, 2016 news item on Nanowerk highlights some research into adhesives and octopuses,

With increased study of bio-adhesives, a significant effort has been made in search for novel adhesives that will combine reversibility, repeated usage, stronger bonds and faster bonding time, non-toxic, and more importantly be effective in wet and other extreme conditions.

A team of Korean scientists-made up of scientists from Korea Institute of Science and Technology (KIST) and UNIST has recently found a way to make building flexible pressure sensors easier–by mimicking the suction cups on octopus’s tentacles.

A July 5, 2016 UNIST (Ulsan National Institute of Science and Technology) press release, which originated the news item, provides more information,

According to the research team, “Although flexible pressure sensors might give future prosthetics and robots a better sense of touch, building them requires a lot of laborious transferring of nano- and microribbons of inorganic semiconductor materials onto polymer sheets.”

In search of an easier way to process this transfer printing, Prof. Hyunhyub Ko (School of Energy and Chemical Engineering, UNIST) and his colleagues turned to the octopus suction cups for inspiration.

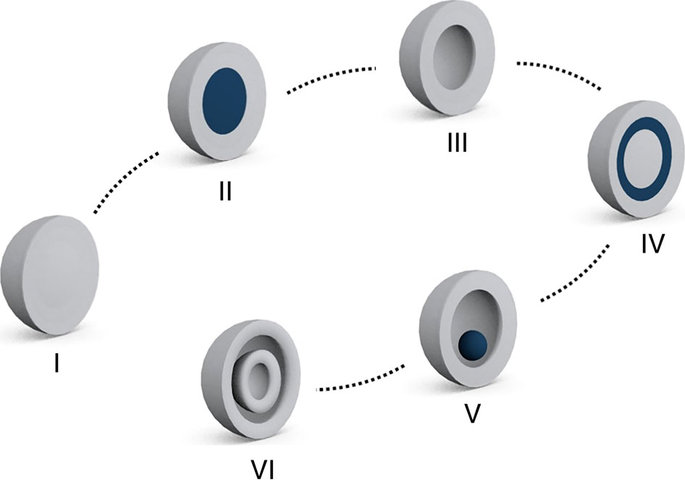

An octopus uses its tentacles to move to a new location and uses suction cups underneath each tentacle to grab onto something. Each suction cup contains a cavity whose pressure is controlled by surrounding muscles. These can be made thinner or thicker on demand, increasing or decreasing air pressure inside the cup, allowing for sucking and releasing as desired.

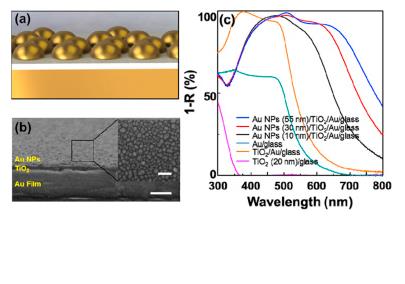

By mimicking muscle actuation to control cavity-pressure-induced adhesion of octopus suckers, Prof. Ko and his team engineered octopus-inspired smart adhesive pads. They used the rubbery material polydimethylsiloxane (PDMS) to create an array of microscale suckers, which included pores that are coated with a thermally responsive polymer to create sucker-like walls.

The team discovered that the best way to replicate organic nature of muscle contractions would be through applied heat. Indeed, at room temperature, the walls of each pit sit in an ‘open’ state, but when the mat is heated to 32°C, the walls contract, creating suction, therby allowing the entire mate to adhere to a material (mimicking the suction function of an octopus). The adhesive strength also spiked from .32 kilopascals to 94 kilopascals at high temperature.

The team reports that the mat worked as envisioned—they made some indium gallium arsenide transistors that sat on a flexible substrate and also used it to move some nanomaterials to a different type of flexible material.

Prof. Ko and his team expect that their smart adhesive pads can be used as the substrate for wearable health sensors, such as Band-Aids or sensors that stick to the skin at normal body temperatures but fall off when rinsed under cold water.

Here’s a link to and a citation for the paper,

Octopus-Inspired Smart Adhesive Pads for Transfer Printing of Semiconducting Nanomembranes by Hochan Lee, Doo-Seung Um, Youngsu Lee, Seongdong Lim, Hyung-jun Kim, and Hyunhyub Ko. Advanced Materials DOI: 10.1002/adma.201601407 Version of Record online: 20 JUN 2016

© 2016 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

This paper is behind a paywall.