Before launching into the news item and if you’re as ignorant about the term as I was, here’s what it means to be a dandelion clock, from the dandelion clock definition on Wiktionary [Note: Links have been removed]),

A single stem of a dandelion in its post-flowering state with the downy covering of its head intact. The term is applied when the flower is used, or is thought of as suitable for use, in a children’s pastime by which the number of puffs needed to blow the filamentous achenes from a dandelion is supposed to tell the time.

A March 3, 2021 news item on phys.org announces dandelion research (Note: A link has been removed),

Fields are covered with dandelions in spring, a very common plant with yellow-gold flowers and toothed leaves. When they wither, the flowers turn into fluffy white seed heads that, like tiny parachutes, are scattered around by the wind. Taraxacum officinale—its scientific name—inspired legends and poems and has been used for centuries as a natural remedy for many ailments.

Now, thanks to a study conducted at the University of Trento [Università di Trento], dandelions will inspire new engineered materials. The air trapping capacity of dandelion clocks [emphasis mine] submerged in water has been measured in the lab for the first time. The discovery paves the way for the development of new and advanced devices and technologies that could be used in a broad range of applications, for example, to create devices or materials that retain air bubbles under water.

…

I found the dandelion squeezing sequence to be quite fascinating.

A March 3, 2021 Università di Trento press release (also on EurekAlert), which originated the news item, provides more detail,

The study was coordinated by Nicola Pugno, professor of the University of Trento and coordinator of the Laboratory of Bio-inspired, Bionic, Nano, Meta Materials & Mechanics at the Department of Civil, Environmental and Mechanical Engineering.

The discovery was given international prominence by “Materials Today Bio”, a multidisciplinary journal focused on the interface between biology and materials science, chemistry, physics, engineering, and medicine.Nicola Pugno outlined how the research unfolded: “Diego Misseroni and I started to work on a discovery that my daughter made, in her first year in high school. She noticed that dandelion clocks, when submerged by water, turn silvery because they trap air. We have quantified this discovery. For the first time, we have measured the air trapping capacity of dandelion clocks in a laboratory setting. This paper demonstrated that kids and young adults can make significant discoveries by observing nature”.

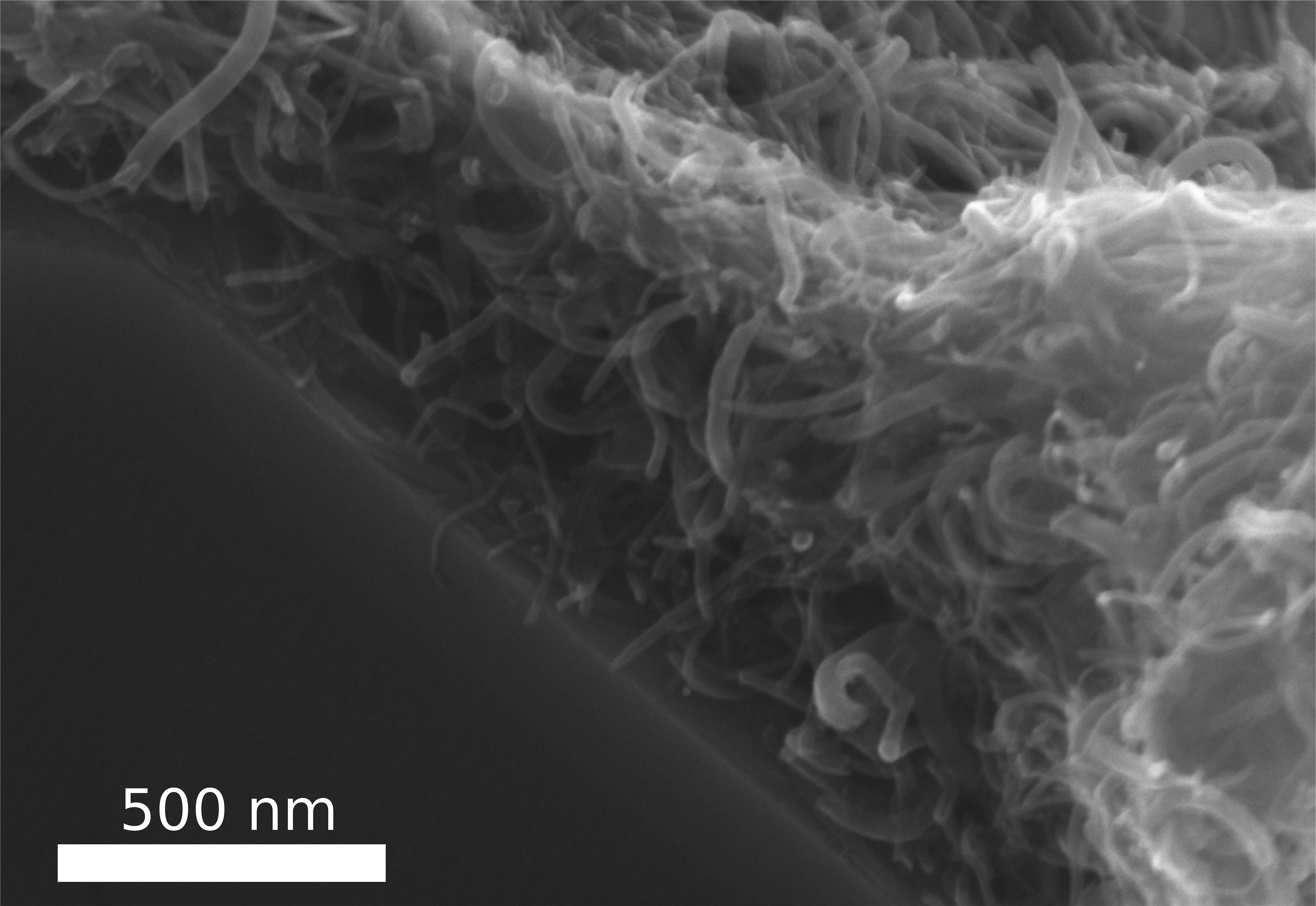

When submerged in water, the research team observed, the soft seed heads turn silver in color, become thinner and take on a rhombus-like shape. The team then developed an analytical model to measure the mechanical properties of the flower, in order to mimic them and create re-engineered dandelion-like materials.

Bioinspired engineering can explore different opportunities thanks to this discovery, such as miniaturized parachute-like elements to develop innovative devices and advanced, light and low-cost technological solutions to trap and transport air bubbles underwater. These materials could be used, for example, in underwater operations.

It’s been a while (see my Nov. 21, 2018 posting ‘Regenerating tooth enamel’) since I’ve featured research from Nicola Pugno here.

Here’s a link to and a citation for Pugno’s dandelion-ispired work

Air-encapsulating elastic mechanism of submerged Taraxacum blowballs by M.C.Pugno, D.Misseroni, N.M.Pugno. Materials Today Bio Volume 9, January 2021, 100095 DOI: 10.1016/j.mtbio.2021.100095

This paper is open access.