Combating a drug addiction ‘crisis’ with a nanotechnology-enabled solution is the main topic although the technology is being implemented for another problem first according to this May 4, 2016 article by John Luciew for pennlive.com (Note: Links have been removed),

Treating pain is a constant in medicine. It’s part of the human condition, known as the “fifth vital sign” among physicians. Effectively treating pain will continue to play a central role in medicine, despite the societal shock waves brought on by the rapid rise in opioid addiction across America.

The fallout from our nation’s opioid addiction crisis is roiling the medical and pharmaceutical industries, where regulatory action is rapidly reining in opioid painkiller prescriptions with new guidelines and stricter controls.

…

By harnessing nanotechnology and small-particles physics, Iroko Pharmaceuticals is developing a new class of low-dose prescription painkillers. Company executives say their line of nonsteroidal anti-inflammatory drugs could be the opioid alternative that the medical community has been looking for amid America’s addiction crisis.

The pharmaceutical company is Pennsylvania-based (US) and it isn’t tackling the ‘opioid addiction crisis’ yet. First, there’s this,

Its new line of prescription painkillers are predicated upon a highly patented process of pulverizing drug molecules so they are up to 100 times smaller, which markedly increases their pain-killing effectiveness at dramatically lower doses.

Right now, Iroko is focusing this nanotechnology on creating a full line of low-dose prescription painkillers based upon the class of drugs known as nonsteroidal anti-inflammatories, or NSAIDs. There are six NSAID molecules, the most common being Ibuprofen. Iroko is planning nanotechnology technology versions for all six NSAID molecules, three of which have already received approval from the Food and Drug Administration.

Luciew has done some homework on the technology,

“We solved a chemistry problem by using physics,” explained Iroko Chairman Osagie Imasogie, who founded the company [Iroko Pharmaceuticals] in 2007.

Yet, the company that actually solved the physics problem was iCeutica, founded in Australia and now based in King of Prussia, Pa.

iCeutica owns the patented SoluMatrix fine particle process that pulverizes drug molecules into nano-sized particles, enabling low doses of a drug to be better absorbed by the body, thus providing faster and far more effective pain relief.

Of course, the practice of crushing and grinding drug powders is as old as the pharmacist’s mortar and pestle. But there’s never been a way of pulverizing a drug molecule into nano particles that was scalable for industrial production — not until iCeutica created its SoluMatrix process, that is.

iCeutica provides a description of the technology on its SoluMatrix webpage,

iCeutica’s proprietary SoluMatrix™ Fine Particle Technology fuels new product development and solves problems of bioavailability, variability, side effects and delivery of marketed or development-stage pharmaceuticals.

The SoluMatrix technology is a scaleable and cost-effective manufacturing process that can produce submicron-sized drug particles that are 10 to 200 times smaller than conventional drug particles. The particles generated using this technology, which both grinds the drug particles into a superfine powder and protects those submicron particles from subsequent agglomeration (or clumping together into big particles), comprise a single unit operation and can be manufactured into tablets, capsules and other dosage forms without further processing.

…

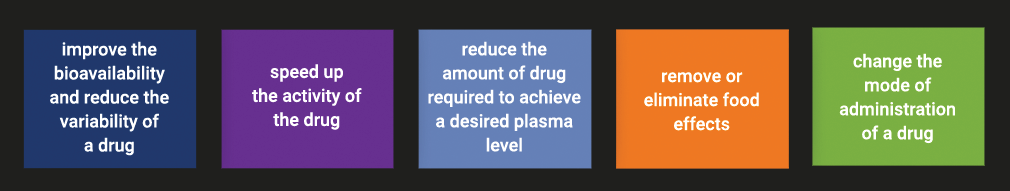

The SoluMatrix technology improves the performance of pharmaceuticals by dramatically changing how the drug dissolves and is absorbed. By making submicron-sized particles of a drug, it is possible to:

Unfortunately there aren’t more details. I’m somewhat puzzled by the submicron measurement why not state the size using the term nanometre?

Getting back to Iroko, Imasogie, impressed with the SoluMatrix technology, has made a major investment in iCeutica and is chair of iCeutica’s board. His homebase company, Iroko holds exclusive global rights to SoluMatrix.

Luciew’s article describes the current situation in the NSAID market,

Iroko officials acknowledge that NSAID painkillers carry their own health risks, including the potential for stomach ulcers, kidney problems and cardio-vascular ailments, up to and including stroke and heart attack. The fears associated with NSAIDs peaked a decade ago with the Vioxx case, a popular prescription NSAID that was eventually taken off the market due to associated cardiac and other risks.

The latest FDA guidelines for NSAID use calls for the lowest effective dose, which precisely describes the nanotechnology-driven low-dose NSAID drugs Iroko is rolling out. What is more, due to the ongoing opioid crisis, both the FDA and the Centers for Disease Control are heavily emphasizing non-opioid alternatives for pain relief, further opening to door for Iroko’s pain products.

That said about the issues with NSAIDs, Luciew outlines Iroko’s current offerings and explains what makes this technology so attractive,

According to Imasogie, Iroko’s line of low-dose, nanotechnology NSAIDs fits both sets of regulatory safety criteria. The new drugs are the lowest effective dose for NSAIDs, and are a viable pain-killing alternative to opioids, especially when it comes to treating osteoarthritis and other moderate pain.

“No one is going to give an NSAID if you have cancer,” Imasogie says. “But for chronic low back pain, yes.”

Three of Iroko’s six low-dose NSAID offerings have already received FDA approval and are on the market:

- Zorvolex (diclofenac), approved in October 2013 for the management of mild to moderate acute pain in adults and in August 2014 for the management of osteoarthritis pain.

- Tivorbex, approved in February 2014 for treatment of mild to moderate acute pain in adults.

- Vivlodex, approved in October 2015 as another option for treatment of osteoarthritis pain. Three more of Iroko’s low-dose NSAIDs are awaiting approval.

These nano drugs are effective at doses of 35 to 40 milligrams to as low as 10 milligrams, the company says. That’s compared to other NSAID doses that start at 200 milligrams. As a result, Iroko’s low-dose NSAID drugs are being marketed as providing a prescription alternative to opioids at the precise moment everyone from the White House to the white-coat-clad family physician is searching for one.

If you the have time and interest, I encourage you to read Luciew’s article in its entirety. He covers more market issues and includes an enbedded video in his piece.

One last note about Iroko Pharmaceuticals, the company is named after a tree found on the African continent and executives of the company have hinted they are experimenting with SoluMatrix to make low-dose opioids available in the future.

While I have my doubts about the opioid addiction ‘crisis’, I do believe that lower, more effective doses of painkillers, regardless of their drug class, can only benefit patients.