It doesn’t look like much but who cares when it does the job and is being made available commercially,

A May 11, 2023 news item on Nanowerk announces the research,

Northwestern University engineers have developed a new sponge that can remove metals — including toxic heavy metals like lead and critical metals like cobalt — from contaminated water, leaving safe, drinkable water behind.

In proof-of-concept experiments, the researchers tested their new sponge on a highly contaminated sample of tap water, containing more than 1 part per million of lead. With one use, the sponge filtered lead to below detectable levels.

After using the sponge, researchers also were able to successfully recover metals and reuse the sponge for multiple cycles. The new sponge shows promise for future use as an inexpensive, easy-to-use tool in home water filters or large-scale environmental remediation efforts.

…

A May 10, 2023 Northwestern University news release on EurekAlert (also received via email) provides more detail, Note: Links have been removed,

The study was published late yesterday (May 10 [2023]) in the journal ACS ES&T Water. The paper outlines the new research and sets design rules for optimizing similar platforms for removing — and recovering — other heavy-metal toxins, including cadmium, arsenic, cobalt and chromium.

“The presence of heavy metals in the water supply is an enormous public health challenge for the entire globe,” said Northwestern’s Vinayak Dravid, senior author of the study. “It is a gigaton problem that requires solutions that can be deployed easily, effectively and inexpensively. That’s where our sponge comes in. It can remove the pollution and then be used again and again.”

Dravid is the Abraham Harris Professor of Materials Science and Engineering at Northwestern’s McCormick School of Engineering and director of global initiatives at the International Institute for Nanotechnology.

Sopping up spills

The project builds on Dravid’s previous work to develop highly porous sponges for various aspects of environmental remediation. In May 2020, his team unveiled a new sponge designed to clean up oil spills. [Note: My June 25, 2020 posting highlights the work and includes an embedded video demonstration of the technology.] The nanoparticle-coated sponge, which is now being commercialized by Northwestern spinoff MFNS Tech, offers a more efficient, economic, ecofriendly and reusable alternative to current approaches to oil spills.

But Dravid knew it wasn’t enough.

“When there is an oil spill, you can remove the oil,” he said. “But there also are toxic heavy metals — like mercury, cadmium, sulfur and lead — in those spills. So, even when you remove the oil, some of the other toxins might remain.

Rinse and repeat

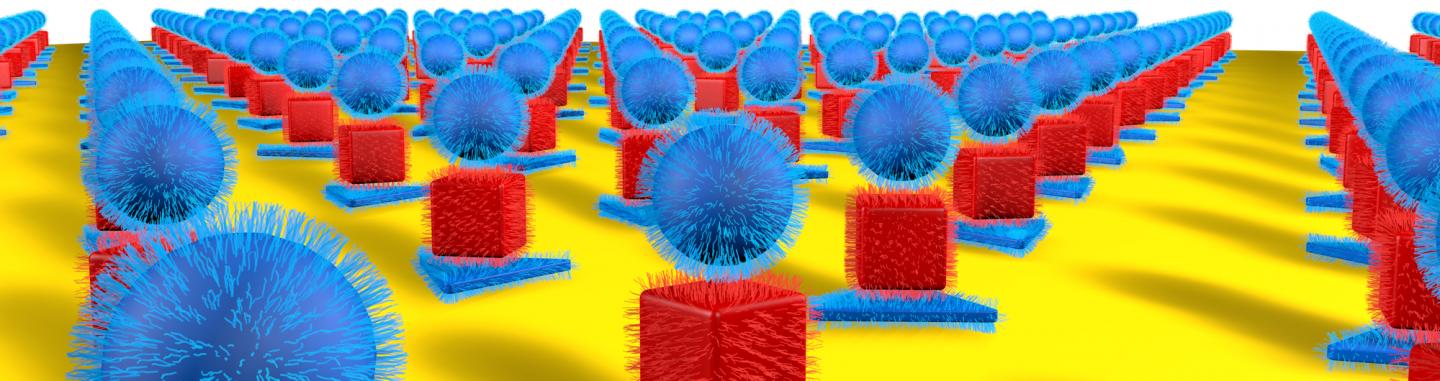

To tackle this aspect of the issue, Dravid’s team, again, turned to sponges coated with an ultrathin layer of nanoparticles. After testing many different types of nanoparticles, the team found that a manganese-doped goethite coating worked best. Not only are manganese-doped goethite nanoparticles inexpensive to make, easily available and nontoxic to human, they also have the properties necessary to selectively remediate heavy metals.

“You want a material with a high surface area, so there’s more room for the lead ions to stick to it,” said Benjamin Shindel, a Ph.D. student in Dravid’s lab and the paper’s first author. “These nanoparticles have high-surface areas and abundant reactive surface sites for adsorption and are stable, so they can be reused many times.”

The team synthesized slurries of manganese-doped goethite nanoparticles, as well as several other compositions of nanoparticles, and coated commercially available cellulose sponges with these slurries. Then, they rinsed the coated sponges with water in order to wash away any loose particles. The final coatings measured just tens of nanometers in thickness.

When submerged into contaminated water, the nanoparticle-coated sponge effectively sequested lead ions. The U.S. Food and Drug Administration requires that bottled drinking water is below 5 parts per billion of lead. In filtration trials, the sponge lowered the amount of lead to approximately 2 parts per billion, making it safe to drink.

“We’re really happy with that,” Shindel said. “Of course, this performance can vary based on several factors. For instance, if you have a large sponge in a tiny volume of water, it will perform better than a tiny sponge in a huge lake.”

Recovery bypasses mining

From there, the team rinsed the sponge with mildly acidified water, which Shindel likened to “having the same acidity of lemonade.” The acidic solution caused the sponge to release the lead ions and be ready for another use. Although the sponge’s performance declined after the first use, it still recovered more than 90% of the ions during subsequent use cycles.

This ability to gather and then recover heavy metals is particularly valuable for removing rare, critical metals, such as cobalt, from water sources. A common ingredient in lithium-ion batteries, cobalt is energetically expensive to mine and accompanied by a laundry list of environmental and human costs.

If researchers could develop a sponge that selectively removes rare metals, including cobalt, from water, then those metals could be recycled into products like batteries.

“For renewable energy technologies, like batteries and fuel cells, there is a need for metal recovery,” Dravid said. “Otherwise, there is not enough cobalt in the world for the growing number of batteries. We must find ways to recover metals from very dilute solutions. Otherwise, it becomes poisonous and toxic, just sitting there in the water. We might as well make something valuable with it.”

Standardized scale

As a part of the study, Dravid and his team set new design rules to help others develop tools to target particular metals, including cobalt. Specifically, they pinpointed which low-cost and nontoxic nanoparticles also have high-surface areas and affinities for sticking to metal ions. They studied the performance of coatings of manganese, iron, aluminum and zinc oxides on lead adsorption. Then, they established relationships between the structures of these nanoparticles and their adsorptive properties.

Called Nanomaterial Sponge Coatings for Heavy Metals (or “Nano-SCHeMe”), the environmental remediation platform can help other researchers differentiate which nanomaterials are best suited for particular applications.

“I’ve read a lot of literature that compares different coatings and adsorbents,” said Caroline Harms, an undergraduate student in Dravid’s lab and paper co-author. “There really is a lack of standardization in the field. By analyzing different types of nanoparticles, we developed a comparative scale that actually works for all of them. It could have a lot of implications in moving the field forward.”

Dravid and his team imagine that their sponge could be used in commercial water filters, for environmental clean-up or as an added step in water reclamation and treatment facilities.

“This work may be pertinent to water quality issues both locally and globally,” Shindel said. “We want to see this out in the world, where it can make a real impact.”

The study, “Nano-SCHeME: Nanomaterial Sponge Coatings for Heavy Metals, an environmental remediation platform,” was supported by the National Science Foundation and U.S. Department of Energy.

Editor’s note: Dravid and Northwestern have financial interests (equities, royalties) in MFNS Tech.

Here’s a link to and a citation for the paper,

Nano-SCHeme: Nanomaterial Sponge Coatings for Heavy Metals, an Environmental Remediation Platform by Benjamin Shindel, Stephanie M. Ribet, Caroline Harms, Vikas Nandwana, and Vinayak P. Dravid. ACS EST Water 2023, XXXX, XXX, XXX-XXX DOI: https://doi.org/10.1021/acsestwater.2c00646 Publication Date:May 10, 2023 © 2023 American Chemical Society

This paper is behind a paywall.

You can find the MFNS Tech website here.