This research into longer lasting bandages described in an August 12, 2022 news item on phys.org comes from McGill University (Montréal, Canada)

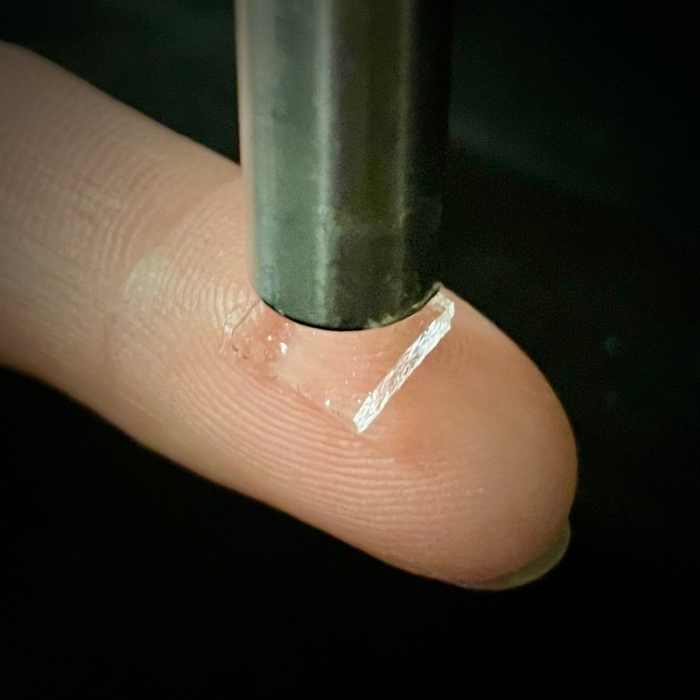

Researchers have discovered that they can control the stickiness of adhesive bandages using ultrasound waves and bubbles. This breakthrough could lead to new advances in medical adhesives, especially in cases where adhesives are difficult to apply such as on wet skin.

“Bandages, glues, and stickers are common bioadhesives that are used at home or in clinics. However, they don’t usually adhere well on wet skin. It’s also challenging to control where they are applied and the strength and duration of the formed adhesion,” says McGill University Professor Jianyu Li, who led the research team of engineers, physicists, chemists, and clinicians.

…

An August 12, 2022 McGill University news release (also on EurekAlert), which originated the news item, delves further into the work,

“We were surprised to find that by simply playing around with ultrasonic intensity, we can control very precisely the stickiness of adhesive bandages on many tissues,” says lead author Zhenwei Ma, a former student of Professor Li and now a Killam Postdoctoral Fellow at the University of British Columbia.

Ultrasound induced bubbles control stickiness

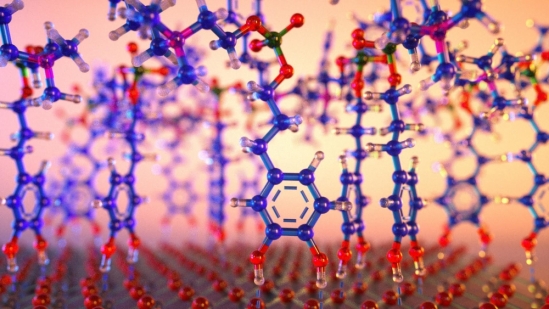

In collaboration with physicists Professor Outi Supponen and Claire Bourquard from the Institute of Fluid Dynamics at ETH Zurich, the team experimented with ultrasound induced microbubbles to make adhesives stickier. “The ultrasound induces many microbubbles, which transiently push the adhesives into the skin for stronger bioadhesion,” says Professor Supponen. “We can even use theoretical modeling to estimate exactly where the adhesion will happen.”

Their study, published in the journal Science, shows that the adhesives are compatible with living tissue in rats. The adhesives can also potentially be used to deliver drugs through the skin. “This paradigm-shifting technology will have great implications in many branches of medicine,” says University of British Columbia Professor Zu-hua Gao. “We’re very excited to translate this technology for applications in clinics for tissue repair, cancer therapy, and precision medicine.”

“By merging mechanics, materials and biomedical engineering, we envision the broad impact of our bioadhesive technology in wearable devices, wound management, and regenerative medicine,” says Professor Li, who is also a Canada Research Chair in Biomaterials and Musculoskeletal Health.

Here’s a link to and a citation for the paper,

Controlled tough bioadhesion mediated by ultrasound by Zhenwei Ma, Claire Bourquard, Qiman Gao, Shuaibing Jiang, Tristan De Iure-Grimmel, Ran Huo, Xuan Li, Zixin He, Zhen Yang, Galen Yang, Yixiang Wang, Edmond Lam, Zu-hua Gao, Outi Supponen and Jianyu Li. Science 11 Aug 2022 Vol 377, Issue 6607 pp. 751-755 DOI: 10.1126/science.abn8699

This paper is behind a paywall.

I haven’t seen this before but it seems that one of the journal’s editors decided to add a standalone paragraph to hype some of the other papers about adhesives in the issue,

A sound way to make it stick

Tissue adhesives play a role in temporary or permanent tissue repair, wound management, and the attachment of wearable electronics. However, it can be challenging to tailor the adhesive strength to ensure reversibility when desired and to maintain permeability. Ma et al. designed hydrogels made of polyacrylamide or poly(N-isopropylacrylamide) combined with alginate that are primed using a solution containing nanoparticles of chitosan, gelatin, or cellulose nanocrystals (see the Perspective by Es Sayed and Kamperman). The application of ultrasound causes cavitation that pushes the primer molecules into the tissue. The mechanical interlocking of the anchors eventually results in strong adhesion between hydrogel and tissue without the need for chemical bonding. Tests on porcine or rat skin showed enhanced adhesion energy and interfacial fatigue resistance with on-demand detachment. —MSL

I like the wordplay and am guessing that MSL is:

Marc S. Lavine

Senior Editor

Education: BASc, University of Toronto; PhD, University of Cambridge

Areas of responsibility: Reviews; materials science, biomaterials, engineering