This bandage not only heals wounds (on rats) much faster; it’s cheap, according to a November 29, 2018 news item on Nanowerk,

A new, low-cost wound dressing developed by University of Wisconsin-Madison engineers could dramatically speed up healing in a surprising way.

The method leverages energy generated from a patient’s own body motions to apply gentle electrical pulses at the site of an injury.

In rodent tests, the dressings reduced healing times to a mere three days compared to nearly two weeks for the normal healing process.

“We were surprised to see such a fast recovery rate,” says Xudong Wang, a professor of materials science and engineering at UW-Madison. “We suspected that the devices would produce some effect, but the magnitude was much more than we expected.”

A November 29, 2018 University of Wisconsin-Madison news release (also on EurekAlert) by Sam Million-Weaver, which originated the news item, expands on the theme,

Researchers have known for several decades that electricity can be beneficial for skin healing, but most electrotherapy units in use today require bulky electrical equipment and complicated wiring to deliver powerful jolts of electricity.

“Acute and chronic wounds represent a substantial burden in healthcare worldwide,” says collaborator Angela Gibson, professor of surgery at UW-Madison and a burn surgeon and director of wound healing services at UW Health. “The use of electrical stimulation in wound healing is uncommon.”

In contrast with existing methods, the new dressing is much more straightforward.

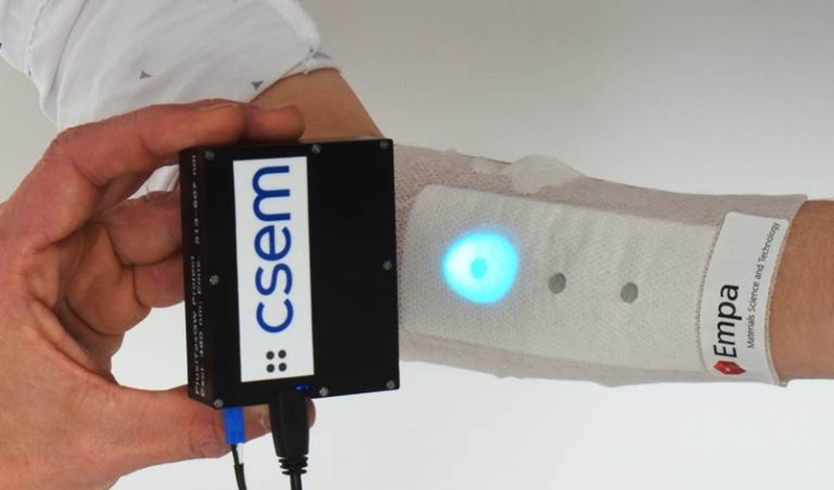

“Our device is as convenient as a bandage you put on your skin,” says Wang.

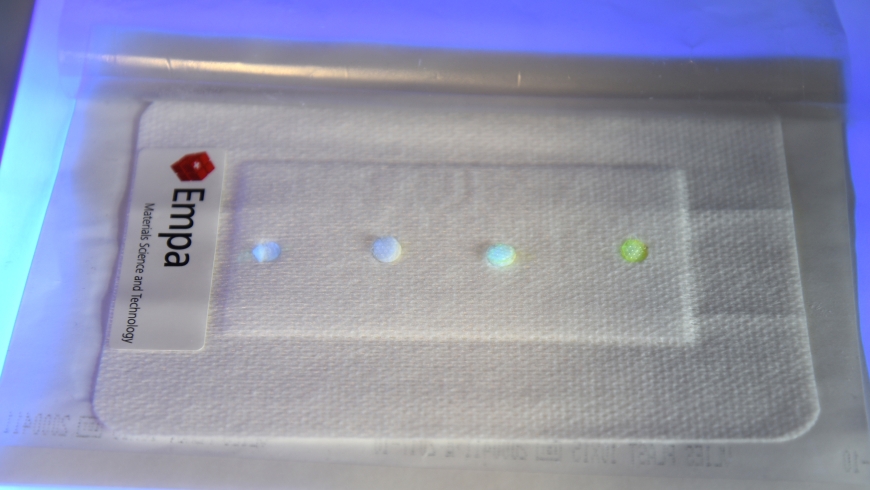

The new dressings consist of small electrodes for the injury site that are linked to a band holding energy-harvesting units called nanogenerators, which are looped around a wearer’s torso. The natural expansion and contraction of the wearer’s ribcage during breathing powers the nanogenerators, which deliver low-intensity electric pulses.

“The nature of these electrical pulses is similar to the way the body generates an internal electric field,” says Wang.

And, those low-power pulses won’t harm healthy tissue like traditional, high-power electrotherapy devices might.

In fact, the researchers showed that exposing cells to high-energy electrical pulses caused them to produce almost five times more reactive oxygen species — major risk factors for cancer and cellular aging — than did cells that were exposed to the nanogenerators.

Also a boon to healing: They determined that the low-power pulses boosted viability for a type of skin cell called fibroblasts, and exposure to the nanogenerator’s pulses encouraged fibroblasts to line up (a crucial step in wound healing) and produce more biochemical substances that promote tissue growth.

“These findings are very exciting,” says collaborator Weibo Cai, a professor of radiology at UW-Madison. “The detailed mechanisms will still need to be elucidated in future work.”

In that vein, the researchers aim to tease out precisely how the gentle pulses aid in healing. The scientists also plan to test the devices on pig skin, which closely mimics human tissue.

And, they are working to give the nanogenerators additional capabilities–tweaking their structure to allow for energy harvesting from small imperceptible twitches in the skin or the thrumming pulse of a heartbeat.

“The impressive results in this study represent an exciting new spin on electrical stimulation for many different wound types, given the simplicity of the design,” says Gibson, who will collaborate with the team to confirm the reproducibility of these results in human skin models.

If the team is successful, the devices could help solve a major challenge for modern medicine.

“We think our nanogenerator could be the most effective electrical stimulation approach for many therapeutic purposes,” says Wang.

And because the nanogenerators consist of relatively common materials, price won’t be an issue.

“I don’t think the cost will be much more than a regular bandage,” says Wang. “The device in itself is very simple and convenient to fabricate.”

Here’s a link to and a citation for the paper,

Effective Wound Healing Enabled by Discrete Alternative Electric Fields from Wearable Nanogenerators by Yin Long, Hao Wei, Jun Li, Guang Yao, Bo Yu, Dalong Ni, Angela LF Gibson, Xiaoli Lan, Yadong Jiang, Weibo Cai, and Xudong Wang. ACS Nano, Article ASAP DOI: 10.1021/acsnano.8b07038 Publication Date (Web): November 29, 2018

Copyright © 2018 American Chemical Society

This paper is open access.

I assume it will be a while before there are human clinical trials.