A Dec. 7, 2015 news item on ScienceDaily announces a new phase for gold has been identified,

A new and stable phase of gold with different physical and optical properties from those of conventional gold has been synthesized by Agency for Science, Technology and Research (A*STAR) researchers [1], Singapore, and promises to be useful for a wide range of applications, including plasmonics and catalysis.

Many materials exist in a variety of crystal structures, known as phases or polymorphs. These different phases have the same chemical composition but different physical structures, which give rise to different properties. For example, two well-known polymorphs of carbon, graphite and diamond, arranged differently, have radically different physical properties, despite being the same element.

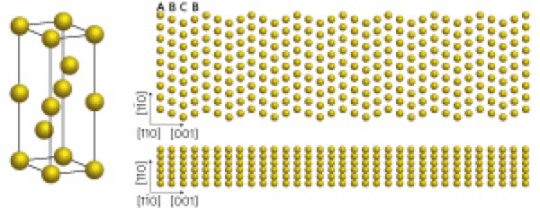

Gold has been used for many purposes throughout history, including jewelry, electronics and catalysis. Until now it has always been produced in one phase ― a face-centered cubic structure in which atoms are located at the corners and the center of each face of the constituent cubes.

Now, Lin Wu and colleagues at the Institute of the A*STAR Institute of High Performance Computing have modeled the optical and plasmonic properties of nanoscale ribbons of a new phase of gold — the 4H hexagonal phase (…) — produced and characterized by collaborators at other institutes in Singapore, China and the USA. The team synthesized nanoribbons of the new phase by simply heating the gold (III) chloride hydrate (HAuCl4) with a mixture of three organic solvents and then centrifuging and washing the product. This gave a high yield of about 60 per cent.

Here’s an image supplied by the researchers,

The atomic structure of the new phase of gold synthesized by A*STAR researchers. Reproduced from Ref. 1 and licensed under CC BY 4.0 © 2015 Z. Fan et al.

A Dec. 2, 2015 A*STAR news release, which originated the news item, provides more details,

The researchers also produced 4H hexagonal phases of the precious metals silver, platinum and palladium by growing them on top of the gold 4H hexagonal phase.

The cubic phase looks identical when viewed front on, from one side or from above. In contrast, the new 4H hexagonal phase lacks this cubic symmetry and hence varies more with direction — a property known as anisotropy. This lower symmetry gives it more directionally varying optical properties, which may make it useful for plasmonic applications. “Our finding is not only is of fundamental interest, but it also provides a new avenue for unconventional applications of plasmonic devices,” says Wu.

The team is keen to explore the potential of their new phase. “In the future, we hope to leverage the unconventional anisotropic properties of the new gold phase and design new devices with excellent performances not achievable with conventional face-centered-cubic gold,” says Wu. The synthesis method also gives rise to the potential for new strategies for controlling the crystalline phase of nanomaterials made from the noble metals.

Here’s a link to and a citation for the paper,

Stabilization of 4H hexagonal phase in gold nanoribbons by Zhanxi Fan, Michel Bosman, Xiao Huang, Ding Huang, Yi Yu, Khuong P. Ong, Yuriy A. Akimov, Lin Wu, Bing Li, Jumiati Wu, Ying Huang, Qing Liu, Ching Eng Png, Chee Lip Gan, Peidong Yang & Hua Zhang. Nature Communications 6, Article number: 7684 doi:10.1038/ncomms8684 Published 28 July 2015

This is an open access paper.