Part 1 covered some of the more formal aspects science culture in Canada, such as science communication education programmes, mainstream media, children’s science magazines, music, etc. Part 2 covered science festivals, art/sci or sciart (depending on who’s talking, informal science get togethers such ‘Cafe Sccientifque’, etc.

This became a much bigger enterprise than I anticipated and so part 3 is stuffed with the do-it-yourself (DIY) biology movement in Canada, individual art/sci or lit/sci projects, a look at what the mathematicians have done and are doing, etc. But first there’s the comedy.

Comedy, humour, and science

Weirdly, Canadians like to mix their science fiction (scifi) movies with humour. (I will touch on more scifi later in this post but it’s too big a topic to cover inadequately, let alone adequately, in this review.) I post as my evidence of the popularity of comedy science fiction films, this from the Category: Canadian science fiction films Wikipedia webpage,

A

Canadian science fiction action films (8 P)

Canadian science fiction adventure films (5 P)

Canadian animated science fiction films (13 P)

C

Canadian science fiction comedy films (19 P)

H

Canadian science fiction horror films (1 C, 58 P)

M

Canadian monster movies (1 P)

T

As you see, comedy science fiction is the second most populated category. Also, the Wikipedia time frame is much broader than mine but I did check one Canadian science fiction comedy film, Bang Bang Baby, a 2014 film, which, as it turns out, is also a musical.

The 2019 iteration of the Vancouver Podcast Festival included the podcast duo, Daniel Chai and Jeff Porter, behind The Fear of Science (which seems to be a science podcast of a humourous bent). They participated in a live https://www.vanpodfest.ca/event/live-podcast-fear-science-vs-vancolour podcast titled, Live Podcast: Fear of Science vs. This is VANCOLOUR.

On further investigation,

Daniel Chai is a Vancouver-based writer, comedian, actor and podcaster. He is co-host of The Fear of Science podcast, which combines his love of learning with his love of being on a microphone. Daniel is also co-founder of The Fictionals Comedy Co and the creator of Improv Against Humanity, and teaches improv at Kwantlen Polytechnic University. He is very excited to be part of Vancouver Podcast Festival, and thanks everyone for listening!

Jeff is the producer and co-host of The Fear of Science. By day, he is a graphic designer/digital developer [according to his LinkedIn profile, he works at Science World], and by night he is a cosplayer, board gamer and full-time geek. Jeff is passionate about all things science, and has been working in science communication for over 4 years. He brings a general science knowledge point of view to The Fear of Science.

Here’s more about The Fear of Science from its homepage (where you will also find links to their podcasts),

A podcast that brings together experts and comedians for an unfiltered discussion about complicated and sometimes controversial science fears in a fun and respectful way.

This podcast seems to have taken life in August 2018.(Well, that’s as far back as the Archived episodes stretch on the website.)

This is Vancolour is a podcast hosted by Mo Amir and you will find this description on the website,

THIS IS A PODCAST ABOUT VANCOUVER AND THE PEOPLE WHO MAKE THIS CITY COLOURFUL

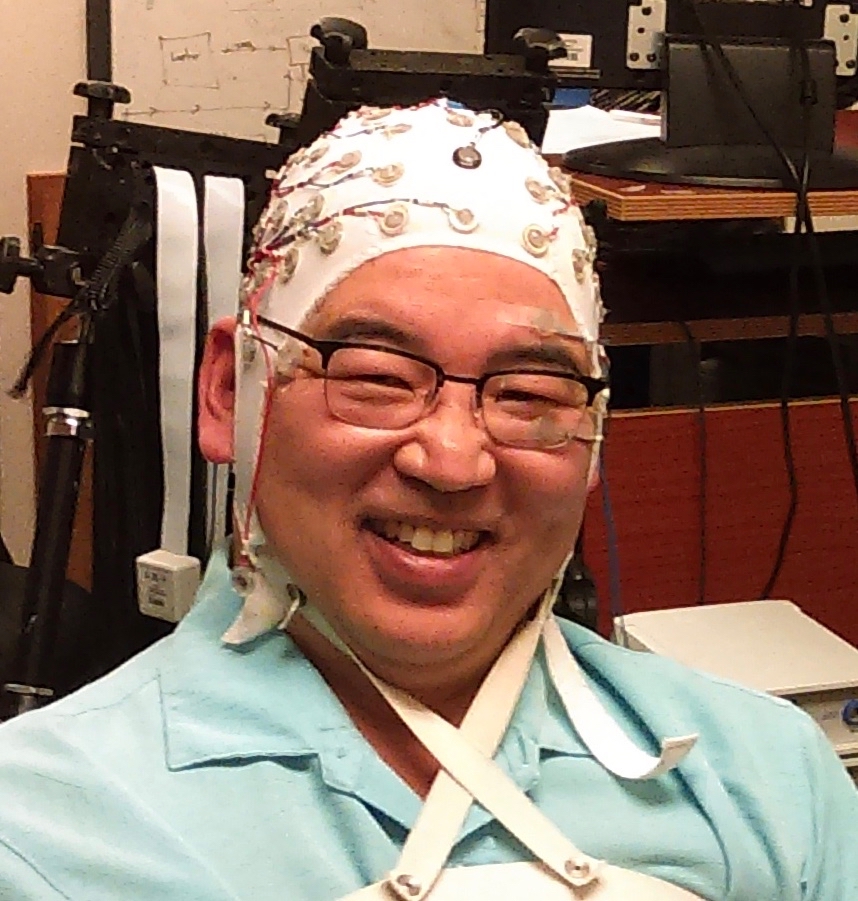

Cartoonist, writer, and educator, Raymond Nakamura produces work for Telus Science World and the Science Borealis science aggregator. His website is known as Raymond’s Brain features this image,

Should you be interested in science comics, a Science Borealis July 8, 2019 blog posting by Raymond Nakamura and Katrina Vera Wong, SciComic: A comic about science comics, offers examples of different styles. Raymond’s twitter feed can be found here. Given the current COVID-19 situation, you might also find Raymond’s April 10, 2020 ‘coping with COVID’ post on SciWhy amusing.

DIY Biology

Much has been happening on this front. First for anyone unfamiliar with do-it-yourself biology, here’s more from its Wikipedia entry,

Do-it-yourself biology (DIY biology, DIY bio) is a growing biotechnological social movement in which individuals, communities, and small organizations study biology and life science using the same methods as traditional research institutions. DIY biology is primarily undertaken by individuals with extensive research training from academia or corporations, who then mentor and oversee other DIY biologists with little or no formal training. This may be done as a hobby, as a not-for-profit endeavour for community learning and open-science innovation, or for profit, to start a business.

A January 21, 2020 posting here listed the second Canadian DIY Biology Summit organized by the Public Health Agency of Canada (PHAC). It was possible to attend virtually from any part of Canada. The first meeting was in 2016 (you can see the agenda here). You’ll see in the agenda for the 2nd meeting in 2020 that there have been a few changes as groups rise into and fall out of existence.

From the 2020 agenda, here’s a list representing the players in Canada’s DIYbio scene,

- Victoria Makerspace (Derek Jacoby)

- Synbiota (Conor Dickie)

- Bricobio (Kevin Chen)

- Open Science Network* (Scott Pownall)

- FREDsense (David Lloyd)

- DIY Bio Toronto (Alaina Hardie)

- Andrew Pelling (Pelling Lab: Augmented Biology; University of Ottawa)

- Marianne Heisz (PHAC Centre for Biosecurity)

- Ruthanne Huising (formerly with McGill University [2008-17]; currently at Emlyon Business School [France])

- Ayoob Ghalami (University of Toronto; senior biosafety officer)

- Stephanie Connolly [formerlyThomson] (University of British Columbia manager Research Safety)

- Marc Saner (University of Ottawa Director, Institute for Science, Society & Policy)

- Hans-Joachim Weiden (Synbridge; Synthetic Biology Maker Space University of Lethbridge)

- Justin Prahara Synbiota

- John Pezacki (Pezacki Lab University of Ottawa)

- Tagny Duff Centre for Applied Synthetic Biology Concordia University

Most of these organizations (e.g., Victoria Makerspace, Synbiota, Bricobio, etc.) seem to be relatively new (founded in 2009 or later) which is quite exciting to think about. This March 13, 2016 article in the Vancouver Observer gives you a pretty good overview of the DIY biology scene in Canada at the time while providing a preview of the then upcoming first DIY Biology summit.

*The Open Science Network in Vancouver was formerly known as DIYbio YVR. I’m not sure when the name change occurred but this July 17, 2018 article by Emily Ng for The Ubyssey (a University of British Columbia student newspaper) gives a little history,

…

In 2009, a group of UBC students and staff recognized these barriers and teamed up to democratize science, increase its accessibility and create an interdisciplinary platform for idea exchange. They created the Open Science Network (OSN).

The Open Science Network is a non-profit society that serves the science and maker community through education, outreach and the provision of space. Currently, they run an open community lab out of the MakerLabs space on East Cordova and Main street, which is a compact space housing microscopes, a freezer, basic lab equipment and an impressive amount of activity.

The lab is home to a community of citizen scientists, professional scientists, artists, designers and makers of all ages who are pursuing their own science projects.

…

Members who are interested in lab work can receive some training in “basic microbiology techniques like pipetting, growing bacteria, using the Polymerase Chain Reaction machine (PCR) [to amplify DNA] and running gels [through a gel ectrophoresis machine to separate DNA fragments by size] from Scott Pownall, a PhD graduate from UBC and the resident microbiologist,” said Wong [ Wes Wong, a staff member of UBC Botany and a founding member of OSN].

The group has also made further efforts to serve their members by offering more advanced synthetic biology classes and workshops at their lab.

…

There is another organization called ‘Open Science Network’ (an ethnobiology group and not part of the Vancouver organization). Here is a link to the Vancouver-based Open Science Network (a community science lab) where they provide further links to all their activities including a regular ‘meetup’.

The word

I have poetry, a book, a television adaptation, three plays with mathematics and/or physics themes and more.

Poetry

In 2012 there was a night of poetry readings in Vancouver. What made it special was that five poets had collaborated with five scientists (later amended to four scientists and a landscape architect) according to my December 4, 2012 posting. The whole thing was conceptualized and organized by Aileen Penner who went on to produce a chapbook of the poetry. She doesn’t have any copies available currently but you can contact her on her website’s art/science page if you are interested in obtaining a copy. She doesn’t seem to have organized any art/science projects since. For more about Aileen Penner who is a writer and poet, go to her website here.

The Banff International Research Station (BIRS) it’s all about the mathematics) hosted a workshop for poets and mathematicians way back in 2011. I featured it (Mathematics: Muse, Maker, and Measure of the Arts) after the fact in my January 9, 2012 posting (scroll down about 30% of the way). If you have the time, do click on my link to Nassif Ghoussoub’s post on his blog (Piece of Mind) about mathematicians, poetry, and the arts. It’s especially interesting in retrospect as he is now the executive director for BIRS, which no longer seems to have workshops that meld any of the arts with mathematics, and science.

One of the guests at that 2011 meeting was Alice Major, former poet laureate for Edmonton and the author of a 2011 book titled, Intersecting Sets: A Poet Looks at Science.

That sadly seems to be it for poetry and the sciences, including mathematics. If you know of any other poetry/science projects or readings, etc. in Canada during the 2010-9 decade, please let me know in the comments.

Books

Karl Schroeder, a Canadian science fiction author, has written many books but of particular interest here are two futuristic novels for the Canadian military.The 2005 novel, Crisis in Zefra, doesn’t fit the time frame I’ve established for this review but the the 2014 novel, Crisis in Urla (scroll down) fits in nicely. His writing is considered ‘realistic’ science fiction in that it’s based on science research and his work is also associated with speculative realism (from his Wikipedia entry; Note: Links have been removed),

Karl Schroeder (born September 4, 1962) is a Canadianscience fiction author. His novels present far-future speculations on topics such as nanotechnology, terraforming, augmented reality, and interstellar travel, and are deeply philosophical.

I wrote about Schroeder and his books for the Canadian military in a two-part posting, Patt One: November 28, 2014 and Part Two: November 28, 2014.

The other author I’m mentioning here is Margaret Atwood. The television adaptation of her book, ‘The Handmaid’s Tale’ has turned a Canadian literary superstar into a supernova (an exploding star whose luminosity can be the equivalent of an entire galaxy). In 2019, she won the Booker Prize, for the second time for ‘The Testaments’ (a followup to ‘The Handmaid’s Tale’), sharing it with Bernardine Evaristo and her book ‘Girl, Woman, Other’. Atwood has described her work (The Handmaid’s Tale, and others) as speculative fiction rather than science fiction. For me, she bases her speculation on the social sciences and humanities, specifically history (read her Wikipedia entry for more).

In 2017 with the television adaptation of ‘The Handmaid’s Tale’, Atwood’s speculative fiction novel became a pop culture phenomenon. Originally published in 1985, the novel was also adapted for a film in 1990 and for an opera in 2000 before it came to television, according to its Wikipedia entry.

There’s a lot more out there, Schroeder and Atwood are just two I’ve stumbled across.

Theatre

I have drama, musical comedy and acting items.

Drama

Pi Theatre’s (Vancouver) mathematically-inclined show, ‘Long Division‘, ran in April 2017 and was mentioned in my April 20, 2017 posting (scroll down about 50% of the way).

This theatrical performance of concepts in mathematics runs from April 26 – 30, 2017 (check here for the times as they vary) at the Annex at 823 Seymour St. From the Georgia Straight’s April 12, 2017 Arts notice,

“Mathematics is an art form in itself, as proven by Pi Theatre’s number-charged Long Division. This is a “refreshed remount” of Peter Dickinson’s ambitious work, one that circles around seven seemingly unrelated characters (including a high-school math teacher, a soccer-loving imam, and a lesbian bar owner) bound together by a single traumatic incident. Directed by Richard Wolfe, with choreography by Lesley Telford and musical score by Owen Belton, it’s a multimedia, movement-driven piece that has a strong cast. … “

You can read more about the production here. As far as I’m aware, there are no upcoming show dates.

There seems to be some sort of affinity between theatre and mathematics, I recently featured (January 3, 2020 posting) a theatrical piece by Hannah Moscovitch titled, ‘Infinity‘, about time, physics, math and more. It had its first production in Toronto in 2015.

John Mighton, a playwright and mathematician, wrote ‘The Little Years’ which has been produced in both Vancouver and Toronto. From a May 9, 2005 article by Kathleen Oliver for the Georgia Straight,

The Little Years is a little jewel of a play: small but multifaceted, and beautifully crafted.

John Mighton’s script gives us glimpses into different stages in the life of Kate, a woman whose early promise as a mathematician is cut short. At age 13, she’s a gifted student whose natural abilities are overlooked by 1950s society, which has difficulty conceiving of women as scientists. Instead, she’s sent to vocational school while her older brother, William, grows up to become one of the most widely praised poets of his generation.

Bruce DeMara had this to say about the play in a November 9, 2012 article for The Star,

John Mighton is a successful playwright and mathematician, yet at times in his life, he’s struggled with doubt. However, he also learned there was hope, and that’s the genesis of The Little Years, which opens at the Tarragon Theatre on Nov. 16 and runs to Dec. 16 [2012].

In keeping (more or less) with this subsection’s theme ‘The Word’, Mighton has recently had a new book published, ‘All Things Being Equal: Why Math is the Key to a Better World’, according to a January 24, 2020 article (online version) by Jamie Portman for Postmedia,

It’s more than two decades since Canadian mathematician and playwright John Mighton found himself playing a small role in the film, Good Will Hunting. What he didn’t expect when he took on the job was that he would end up making a vital contribution to a screenplay that would go on to win an Oscar for its writers, Ben Affleck and Matt Damon.

What happened on that occasion tells you a great deal about Mighton’s commitment to the belief that society grossly underestimates the intellectual capacity of human beings — a belief reiterated with quiet eloquence in his latest book, All Things Being Equal.

…

Mighton loved the experience but as shooting continued he became troubled over his involvement in a movie that played “heavily on the idea that geniuses like Will are born and not made.” This was anathema to his own beliefs as a mathematician and he finally summoned up the courage to ask Affleck and Damon if he could write a few extra lines for his character. This speech was the result: “Most people never get the chance to see how brilliant they can be. They don’t find teachers who believe in them. They get convinced they’re stupid.”

At a time of growing controversy across Canada over the teaching of mathematics in school and continuing evidence of diminishing student results, Mighton continues to feel gratitude to the makers of Good Will Hunting for heeding his concerns. [I will be writing a post about the latest PISA scores where Canadian students have again slipped in their mathematics scores.]

…

Mighton is on the phone from from Toronto, his voice soft-spoken but still edged with fervour. He pursues two successful careers — as an award-winning Canadian playwright and as a renowned mathematician and philosopher who has devoted a lifetime to developing strategies that foster the intellectual potential of all children through learning math. But even as he talks about his 2001 founding of JUMP Math, a respected charity that offers a radical alternative to conventional teaching of the subject, he’s anxious to remind you that he’s a guy who almost failed calculus at university and who once struggled to overcome his “own massive math anxiety.”

…

You can find out more about John Mighton in his Wikipedia entry (mostly about his academic accomplishments) and on the JUMP Math website (better overall biography).

Musical Comedy

It’s called ‘Math Out Loud’ and was first mentioned here in a January 9, 2012 posting (the same post also featured the BIRS poetry workshop),

I found out about the math musical in a Jan. 5, 2012 community newspaper article by Martha Perkins (for the WestEnder),

“When Mackenzie Gray talks about the way Paul McCartney used a recursive sequence to make the song “I Want You (She’s So Heavy)” seem to last forever, you realize that part of the Beatles’ phenomenal success might have sprung from McCartney’s genius as a mathematician.

When Roger Kemp draws on a napkin to illustrate that you just have to change the way you think about numbers to come up with a binary code for pi (as in 3.14 ad infinitum), you get a sense that math can actually be a lot of fun.”

Produced by MITACS which in 2012 was known as ‘Mathematics of Information Technology and Complex Systems’, a not-for-profit research organization, the musical went on tour in the Fall of 2012 (according to my September 7, 2012 posting). Unusually, I did not embed the promotional trailer for this 2012 musical so, here it is now,

Since 2012, Mitacs has gone through some sort of rebranding process and it’s now described as a nonprofit national research organization. For more you can read its Wikipedia entry or go to its website.

Acting and storytelling

It turns out there was an acting class (five sessions) for scientists at the University of Calgary in 2017. Here’s more from the course’s information sheet,

Act Your Science: Improve Your Communication Skills with Training in Improvisation

2 hours a session, 5 sessions, every Wednesday starting November 14 [2017]

…Dr. Jeff Dunn, Faculty of Graduate Studies, Graduate Students Association, the Canadian Science Writers Association [also known as Science Writers and Communicators of Canada] and the Loose Moose Theatre have teamed together to provide training in a skill which will be useful where ever your career takes you.

The goal of this project is to improve the science communication skills of graduate students in science fields. We will improve your communication through the art of training in improvisation. Training will help with speech and body awareness. Improvisation will provide life‐long skills in communication, in a fun interactive environment.

For many years, Alan Alda, a well-known actor (originally of the “MASH” television series fame), has applied his acting skills and improvisation training to help scientists improve their communication. He developed the Alan Alda Centre for Communicating Science at Stony Brook University.

…

The training will involve five 2hr improvisation workshop sessions led by one of Canada’s top professional improvisation trainers, Dennis Cahill, the Artistic Director from Loose Moose Theatre. Dennis has an international reputation for developing the theatrical style of improvisation. Training involves a lot of moving around (and possibly rolling on the floor!) so dress casually. Be prepared to release your inhibitions!

…

The information sheet includes a link to this University of Chicago video (posted on Youtube February 24, 2014) of actor Alan Alda discussing science communication,

Dr. Jeff Dunn, mentioned in the information sheet, has his own website and it’s worth checking out (he has some very interesting ideas). You can also find out more about him and his brain imaging research here.

As for the storytelling, we’re back at the University of Calgary. A student video and storytelling workshop and contest (Innovation Untold) was held on Tuesday, February 4, 2020. Here’s more from the University of Calgary event page for Storytelling Workshop: Do photos and videos have voices?,

…

About the speaker:

Victoria Bouvier, a Michif-Metis woman, is of the Red River Settlement and Boggy Creek, Manitoba, and born and raised in Calgary. She is an Assistant professor in Indigenous Studies at Mount Royal University and a doctoral candidate in Educational Research [emphasis mine] at the University of Calgary. Her research is exploring how Michif/Métis people, born and raised in urban environments, practice and express their self-understandings, both individually and collectively through using an Indigenous oral system and visual media as methodology.

This event is supported by the Research Support Fund and Incremental Project Grant.

Cost: Free

Here’s more about the workshop,

…

In a technology-laden society, people are capturing millions of photographs and videos that document their lived experiences, followed by uploading them to social media sites. As mass amounts of media is being shared each day, the question becomes: are we utilizing photos and videos to derive meaning from our everyday lived experiences, while settling in to a deeper sense of our self-in-relation?

This session will explore how photos and videos, positioned within an Indigenous oral system, are viewed and interacted with as a third perspective in the role of storytelling.

…

More details can be found at the University of Calgary event page for Storytelling Workshop: Do photos and videos have voices?

Finally, h/t to Jennifer Bon Bernard’s April 19, 2017 article (reposted Dec. 11, 2019) about Act Your Science for the Science Writers and Communicators blog. The original date doesn’t look right to me but perhaps she participated in a pilot project.

Neuroscience, science policy, and science advice

The end of this part is almost in sight

Knitting in Toronto and drawings in Vancouver (neuroscience)

In 2017, Toronto hosted a neuroscience event which combined storytelling and knitting (from my October 12, 2017 posting (Note: the portion below is an excerpt from an ArtSci Salon announcement),

With NARRATING NEUROSCIENCE we plan to initiate a discussion on the role and the use of storytelling and art (both in verbal and visual forms) to communicate abstract and complex concepts in neuroscience to very different audiences, ranging from fellow scientists, clinicians and patients, to social scientists and the general public. We invited four guests to share their research through case studies and experiences stemming directly from their research or from other practices they have adopted and incorporated into their research, where storytelling and the arts have played a crucial role not only in communicating cutting edge research in neuroscience, but also in developing and advancing it.

Here’s where the knitting came in (also from my October 12, 2017 posting ,

The ArtSci Salon folks also announced this (from the Sept. 25, 2017 ArtSci Salon announcement; received via email),

ATTENTION ARTSCI SALONISTAS AND FANS OF ART AND SCIENCE!!

CALL FOR KNITTING AND CROCHET LOVERS!In addition to being a PhD student at the University of Toronto, Tahani Baakdhah is a prolific knitter and crocheter and has been the motor behind two successful Knit-a-Neuron Toronto initiatives. We invite all Knitters and Crocheters among our ArtSci Salonistas to pick a pattern

(link below) and knit a neuron (or 2! Or as many as you want!!)BRING THEM TO OUR OCTOBER 20 ARTSCI SALON!

Come to the ArtSci Salon and knit there!

That link to the patterns is still working.

Called “The Beautiful Brain” and held in the same time frame as Toronto’s neuro event, Vancouver hosted an exhibition of Santiago Ramon y Cajal’s drawings from September 5 to December 3, 2017. In concert with the exhibition, the local ‘neuro’ community held a number of outreach events. Here’s what I had in my September 11, 2017 posting where I quoted from the promotional material for the exhibition,

…

The Beautiful Brain is the first North American museum exhibition to present the extraordinary drawings of Santiago Ramón y Cajal (1852–1934), a Spanish pathologist, histologist and neuroscientist renowned for his discovery of neuron cells and their structure, for which he was awarded the Nobel Prize in Physiology and Medicine in 1906. Known as the father of modern neuroscience, Cajal was also an exceptional artist. He combined scientific and artistic skills to produce arresting drawings with extraordinary scientific and aesthetic qualities.

A century after their completion, Cajal’s drawings are still used in contemporary medical publications to illustrate important neuroscience principles, and continue to fascinate artists and visual art audiences. …

Pictured: Santiago Ramón y Cajal, injured Purkinje neurons, 1914, ink and pencil on paper. Courtesy of Instituto Cajal (CSIC).

From Vancouver, the exhibition traveled to a gallery in New York City and then onto the Massachusetts Institute of Technology (MIT).

Science policy

The Canadian Science Policy Centre (CSPC)* sprung to life in 2009 when it held its first science policy conference according to my April 22, 2010 posting (scroll down about 60^ of the way).

Mehrdad Hariri has done a an extraordinary job as its founder and chief executive officer. The CSPC has developed from a single annual conference to an organization that hosts different events throughout the year and publishes articles and opinion pieces on Canadian science policy and has been instrumental in the development of a Canadian science policy community.

The magnitude of Hariri’s accomplishment becomes clear when reading J.w. Grove’s [sic] article, Science Policy, in The Canadian Encyclopedia and seeing that the most recent reports on a national science policy seem to be the Science Council’s (now defunct) 4th report in 1968, Towards a National Science Policy in Canada, the OECD’s (Organization for Economic Cooperation and Development) 1969 Review of [Canada’s] Science Policy, and 3 reports from the Senate’s Lamontagne Committee (Special Committee on Science Policy). Grove’s article takes us only to 1988 but I have been unable to find any more recent reports focused on a national science policy for Canada. (If you have any information about a more recent report, please do let me know in the comments.)

A November 5, 2019 piece (#VoteScience: lessons learned and building science advocacy beyond the election cycle) on the CSPC website further illustrates how the Canadian science policy community has gained ground (Note: Links have been removed),

… on August 8, 2019, a coalition of Canadian science organizations and student groups came together to launch the #VoteScience campaign: a national, non-partisan effort to advocate for science in the federal elections, and make science an election issue.

Specifically, we — aka Evidence for Democracy, Science & Policy Exchange (SPE), and the Toronto Science Policy Network (TSPN) [emphases mine] — built a collection of tools and resources to empower Canadian scientists and science supporters to engage with their local candidates on science issues and the importance of evidence-informed decision-making. Our goal was to make it easy for as many Canadians as possible to engage with their candidates — and they did.

Over the past three months, our #VoteScience portal received over 3,600 visitors, including 600 visitors who used our email form to reach out directly to their local candidates. Collectively, we took #VoteScience selfies, distributed postcards to supporters across Canada, and even wrote postcards to every sitting Member of Parliament (in addition to candidates from all parties in each of our own ridings). Also of note, we distributed a science policy questionnaire to the federal parties, to help better inform Canadians about where the federal parties stand on relevant science issues, and received responses from all but one party. We’ve also advocated for science through various media outlets, including commenting for articles appearing in The Narwhal and Nature News, and penning op-eds for outlets such as the National Observer, University Affairs, Le Devoir, and Découvrir.

…

Also in 2009, the Science & Policy Exchange (SPE) was founded by students in Montréal; in 2012, Evidence for Democracy (E4D) evolved from a protest movement into a permanent organization; and, in 2018, the Toronto Science Policy Network (TSPN) at the University of Toronto sprang into existence.

While the 2019 federal election did not feature a debate about science in Canada, the 2015 election did as I noted in an October 7, 2015 posting.

At the provincial level, there’s the Science & Policy Integration Network (SPIN), which is in British Columbia and was founded some time in 2018. (SPIN’s 2018 conference was featured in an April 5, 2018 posting.)

Prior to SPIN, the Council of Canadian Academies (CCA; more about them in part 4), issued a 2017 report titled, Science Policy: Considerations for Subnational Governments. The report was the outcome of a 2016 CCA workshop originally titled, Towards a Science Policy in Alberta. I gather the scope broadened.

Interesting trajectory, yes?

Chief Science advisors/scientists

In September 2017, the Canadian federal government announced that a Chief Science Advisor, Dr. Mona Nemer, had been appointed. I have more about the position and Dr. Nemer in my September 26, 2017 posting. (Prior to Dr. Nemer’s appointment a previous government had discontinued a National Science Advisor position that existed from 2004 to 2008.)

The Office of the Chief Science Advisor released it first annual report in 2019 and was covered here in a March 19, 2019 posting.

Québec is the only province (as far as I know) to have a Chief Scientist, Rémi Quirion who was appointed in 2011.

Onto Part 4 where you’ll find we’ve gone to the birds and more.

For anyone who missed them:

Part 1 covers science communication, science media (mainstream and others such as blogging) and arts as exemplified by music and dance: The decade that was (2010-19) and the decade to come (2020-29): Science culture in Canada (1 of 5).

Part 2 covers art/science (or art/sci or sciart) efforts, science festivals both national and local, international art and technology conferences held in Canada, and various bar/pub/café events: The decade that was (2010-19) and the decade to come (2020-29): Science culture in Canada (2 of 5).

*The Canadian Science Policy Centre (CSPC) section was written sometime in February 2020. I believe they are planning to publish an editorial piece I submitted to them on April 20, 202 (in other words, before this post was published) in response to their call for submissions (see my April 1, 2020 post for details about the call). In short, I did not praise the organization with any intention of having my work published by them. (sigh) Awkward timing.