I love the look and the theme for this “Living Machines” conference, which seems to be water,

A June 28, 2023 Istituto Italiano di Tecnologia (IIT) press release (also on EurekAlert) provides more detail about the conference,

Now in its twelfth year, the international conference “Living Machines”, organised by Istituto Italiano di Tecnologia (Italian Institute of Technology, IIT), returns to Italy and comes to Genoa for the first time, from 10 to 13 July. Around one hundred experts from all over the world are expected, and they will present their achievements in the field of bio-inspired science and technology. The conference will take place in an exceptional venue, the Acquario di Genova (Genoa Aquarium), which, having reached its 30th birthday, is the ideal location at which to bring together various subject areas, from biology to artificial intelligence and robotics, with a focus on sustainability and environmental protection.

The scientific organiser of the event is Barbara Mazzolai, Associate Director for Robotics and head of the Bioinspired Soft Robotics Lab at IIT, along with Fabian Meder, researcher in the Bioinspired Soft Robotics Lab group and co-chair of the conference programme.

The conference will include two events open to the public: an exhibition area, which will be accessible from 11 to 13 July in the afternoon (from 2 to 4.30 pm); and a scientific café, which will take place on the 12 July at 5 pm. The conference will be an opportunity for international guests to appreciate the region’s beauty and talents, and it will also include the participation of students from the Niccolò Paganini Conservatory of Music. In addition, a satellite event of the conference will be the ISPA – Italian Sustainability Photo Award – exhibition, which will open at Palazzo Ducale on 10 July at 6 p.m.

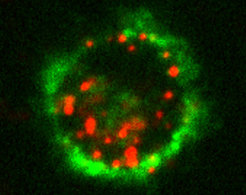

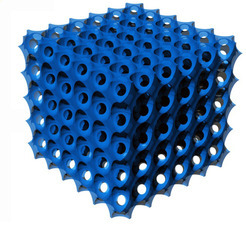

The “Living Machines” conference is the landmark event for the international scientific community which bases its research on living organisms, such as human beings and other animal species – terrestrial, marine, and airborne – in addition to plants, fungi, and bacteria, in order to create so-called “living machines”, in other words, forms of technology capable of replicating their structure and mechanisms of operation.

“The conference is rooted in the union between robotics and neuroscience, using man and other animal species as a model for the study of intelligence and control systems,” said Barbara Mazzolai, Associate Director for Robotics at IIT. “This year the conference will focus on the role of biomimicry in the creation of robots that are more sustainable, with applications for the challenges of environmental protection and human health. Discussions will revolve around the development of robots with a lower energy impact, made using recyclable and biodegradable materials, and that can be used in emergency situations or extreme environments, such as deep sea, soil, space, or environmental disasters, but also for precision agriculture, environmental surveillance, infrastructure monitoring, human care and medical-surgical assistance.”

In the conference programme, experts will take part in a first day of parallel workshop and tutorial sessions (on 10 July), during which the topics of bioinspiration and biohybrid technology in the fields of medicine and the marine environment will be addressed. This first day will be followed by three days of plenary sessions, featuring talks by internationally-renowned scientists. More specifically: Oussama Khatib, one of the pioneers of robotics and director of the Robotics Laboratory at Stanford University; Marco Dorigo, professor at the Université Libre de Bruxelles and one of the pioneers of collective intelligence; Peter Fratzl, director of the Max Planck Institute of Colloids and Interfaces, working on research into osteoporosis and tissue regeneration; Eleni Stavrinidou, coordinator of the “Electronic Plants” group at Linköping University and an expert in bioelectronic and biohybrid systems; Olga Speck, Principal Researcher at the University of Freiburg, specialising in biomimetic materials and the regenerative capabilities of plants; and Kyu-Jin Cho, director of the Research Centre for Soft Robotics and the Biorobotics Laboratory at Seoul National University, one of the world’s leading experts on soft robotics.

For conference participants only, the programme includes: a visit to the Acquario, guided by the facility’s scientific staff, who will illustrate the work and practices needed for the protection and conservation of marine species and the undergoing research projects; an exhibition area for prototypes and products by research groups and companies operating in this field; and a dinner at Villa Lo Zerbino, with a musical contribution by students from the Niccolò Paganini Conservatory.

Open to the general public, on 12 July from 5 p.m. to 6 p.m. there will be a round table entitled “Living Machines: The Origin and the Future” chaired by science journalist Nicola Nosengo, Chief Editor of Nature Italy. Speakers will include Cecilia Laschi from the National University of Singapore, Vickie Webster-Wood from Carnegie Mellon University, Thomas Speck from the University of Freiburg and Paul Verschure from Radboud University Nijmegen.

A satellite initiative of the conference will be the exhibition for ISPA, the Italian Sustainability Photo Award, which will open at Palazzo Ducale on 10 July at 6.00 p.m. ISPA is the photographic award created by the Parallelozero agency in cooperation with the main sponsor PIMCO, to raise public awareness of environmental, social, and governance sustainability issues, encapsulated in the acronym ESG. The works of the winning photographers and finalists in the last three editions will be on display in Genoa: a selection of images that depict the emblematic stories of Italy, a nation moving towards a more sustainable future, a visual narrative that makes it easier to understand the country’s progress in research and innovation.

The organisations supporting the event include, in addition to the principal organiser Istituto Italiano di Tecnologia (Italian Institute of Technology), the international Convergent Science Network [emphasis mine], the Office of Naval Research, Radboud University Nijmegen, and the Living, Adaptive and Energy-autonomous Materials Systems Cluster of Excellence in Freiburg.

Event website: https://livingmachinesconference.eu/2023/

I was particularly struck by this quote, “The conference is rooted in the union between robotics and neuroscience [emphasis mine], using man and other animal species as a model for the study of intelligence and control systems,” from Barbara Mazzolai as I have an as yet unpublished post for a UNESCO neurotechnology event coming up on July 13, 2023. These events come on the heels of a May 16, 2023 Canadian Science Policy Centre panel discussion on responsible neurotechnology (see my May 12, 2023 posting).

For the curious, you can find the Convergent Science Network here.