Unlike today’s (April 28, 2016) earlier piece about dealing with bacteria, the focus for this research is on superbugs and not the bacteria which form biofilm on medical implants and such. An April 21, 2016 news item on RTE News makes the announcement about a new means of dealing with superbugs,

A discovery by a team of scientists in Ireland could stem the spread of deadly superbugs predicted to kill millions of people worldwide over the coming decades.

The research has found an agent that can be baked into everyday items like smart-phones and door handles to combat the likes of MRSA and E. coli.

The nanotechnology has a 99.9 % kill rate of potentially lethal and drug-resistant bacteria, they say.

Lead scientist Professor Suresh C. Pillai, of Sligo Institute of Technology’s Nanotechnology Research Group, says the discovery is the culmination of 12 years work.

“This is a game changer,” he said.

“This breakthrough will change the whole fight against superbugs. It can effectively control the spread of bacteria.”

An April 21, 2016 Sligo Institute of Technology press release provides some context for the work and a few details about the coating,

News of the discovery comes just days after UK Chancellor of the Exchequer George Osborne warned that superbugs could become deadlier than cancer and are on course to kill 10 million people globally by 2050.

Speaking at the International Monetary Fund (IMF) in Washington, Mr Osborne warned that the problem would slash global GDP by around €100 trillion if it was not tackled.

Using nanotechnology, the discovery is an effective and practical antimicrobial solution — an agent that kills microorganisms or inhibits their growth — that can be used to protect a range of everyday items.

Items include anything made from glass, metallics and ceramics including computer or tablet screens, smartphones, ATMs, door handles, TVs, handrails, lifts, urinals, toilet seats, fridges, microwaves and ceramic floor or wall tiles.

It will be of particular use in hospitals and medical facilities which are losing the battle against the spread of killer superbugs.

Other common uses would include in swimming pools and public buildings, on glass in public buses and trains, sneeze guards protecting food in delis and restaurants as well as in clean rooms in the medical sector.

…

“It’s absolutely wonderful to finally be at this stage. This breakthrough will change the whole fight against superbugs. It can effectvely control the spread of bacteria,” said Prof. Pillai.

He continued: “Every single person has a sea of bacteria on their hands. The mobile phone is the most contaminated personal item that we can have. Bacteria grows on the phone and can live there for up to five months. As it is contaminated with proteins from saliva and from the hand, It’s fertile land for bacteria and has been shown to carry 30 times more bacteria than a toilet seat.”

The research started at Dublin Institute of Technology (DIT)’s CREST and involves scientists now based at IT Sligo, Dublin City University (DCU) and the University of Surrey. Major researchers included Dr Joanna Carroll and Dr Nigel S. Leyland.

It has been funded for the past eight years by John Browne, founder and CEO of Kastus Technologies Ltd, who is bringing the product to a global market. He was also supported by significant investment from Enterprise Ireland.

As there is nothing that will effectively kill antibiotic-resistant superbugs completely from the surface of items, scientists have been searching for a way to prevent the spread.

This has been in the form of building or ‘baking’ antimicrobial surfaces into products during the manufacturing process.

However, until now, all these materials were toxic or needed UV light in order to make them work. This meant they were not practical for indoor use and had limited commercial application.

“The challenge was the preparation of a solution that was activated by indoor light rather than UV light and we have now done that,” said Prof Pillai.

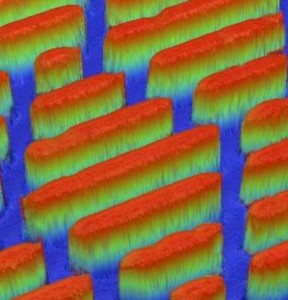

The new water-based solution can be sprayed onto any glass, ceramic or metallic surface during the production process, rendering the surface 99.9 per cent resistant to superbugs like MRSA, E. coli and other fungi. [emphasis mine]

The solution is sprayed on the product — such as a smartphone glass surface — and then ‘baked’ into it, forming a super-hard surface. The coating is transparent, permanent and scratch resistant and actually forms a harder surface than the original glass or ceramic material.

The team first developed the revolutionary material to work on ceramics and has spent the last five years adapting the formula – which is non-toxic and has no harmful bi-products ‑- to make it work on glass and metallic surfaces.

Research is now underway by the group on how to adapt the solution for use in plastics and paint, allowing even wider use of the protective material.

Prof Pillai, Kastus and the team have obtained a US and a UK patent on the unique process with a number of global patent applications pending. It is rare for such an academic scientific discovery to have such commercial viability.

“I was sold on this from the first moment I heard about it. It’s been a long road to here but it was such a compelling story that it was hard to walk away from so I had to see it through to the end,” said John Browne, Kastus CEO.

He continued: “This is a game changer. The uniqueness of antimicrobia surface treatment means that the applications for it in the real world are endless. The multinational glass manufacturers we are in negotiations with to sell the product to have been searching for years to come up with such a solution but have failed.”

If the coating kills 99.9%, doesn’t that mean 0.1% are immune? If that’s the case, won’t they reproduce and eventually establish themselves as a new kind of superbug?

Here’s a link to and a citation for the paper,

Highly Efficient F, Cu doped TiO2 anti-bacterial visible light active photocatalytic coatings to combat hospital-acquired infections by Nigel S. Leyland, Joanna Podporska-Carroll, John Browne, Steven J. Hinder, Brid Quilty, & Suresh C. Pillai. Scientific Reports 6, Article number: 24770 (2016) doi:10.1038/srep24770 Published online: 21 April 2016

This paper is open access.