Researchers at the University of Toronto (Ontario) and St. Francis Xavier University (Nova Scotia) have received funding from Carbon Management Canada (a Network Centre for Excellence [NCE]) to develop an ultra-sensitive and affordable CO2 nanosensor. From the Feb. 4, 2013 news item on Nanowerk,

Researchers at the Universities of Toronto and St. Francis Xavier are developing an affordable, energy efficient and ultra-sensitive nano-sensor that has the potential to detect even one molecule of carbon dioxide (CO2).

Current sensors used to detect CO2 at surface sites are either very expensive or they use a lot of energy. And they’re not as accurate as they could be. Improving the accuracy of measuring and monitoring stored CO2 is seen as key to winning public acceptance of carbon capture and storage as a greenhouse gas mitigation method.

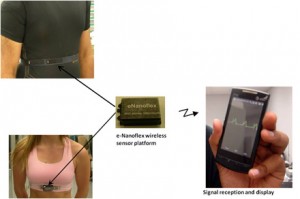

With funding from Carbon Management Canada (CMC), Dr. Harry Ruda of the Centre for Nanotechnology at the University of Toronto and Dr. David Risk of St. Francis Xavier are working on single nanowire transistors that should have unprecedented sensitivity for detecting CO2 emissions.

The Carbon Management Canada (CMC) Feb. 4, 2013 news release, which originated the news item, provides details about the funding and reasons for the research,

CMC, a national network that supports game-changing research to reduce CO2 emissions in the fossil energy industry as well as from other large stationary emitters, is providing Ruda and his team $350,000 over three years. [emphasis mine] The grant is part of CMC’s third round of funding which saw the network award $3.75 million to Canadian researchers working on eight different projects.

The sensor technology needed to monitor and validate the amount of CO2 being emitted has not kept pace with the development of other technologies required for carbon capture and storage (CCS), says Ruda.

“This is especially true when it comes to surface monitoring verification and accounting (MVA),” he says. “Improving MVA is essential to meet the potential of carbon capture and storage.”

And that’s where the ultra-sensitive sensor comes in. “It’s good for sounding the alarm but it’s also good from a regulatory point of view because you want to able to tell people to keep things to a certain level and you need sensors to ensure accurate monitoring of industrial and subsurface environments,” Ruda says.

Given CMC’s vision for ‘game-changing research to reduce carbon emissions’, it bears noting that this organization is located in Calgary (the street address ‘EEEL 403, 2500 University Drive NW Calgary‘ as per my search today [Feb.4.13] on Google [https://www.google.ca/search?q=CMC+address+Calgary&ie=utf-8&oe=utf-8&aq=t&rls=org.mozilla:en-US:official&client=firefox-a] suggests the University of Calgary houses the organization). Calgary is the home of the Canadian fossil fuel industry and a centre boasting many US-based fossil fuel-based companies due to its size and relative proximity to the Alberta oil sands (aka, Athabaska oil sands). From the Wikipedia essay (Note: Links and footnotes have been removed),

The Athabasca oil sands or Athabasca tar sands are large deposits of bitumen or extremely heavy crude oil, located in northeastern Alberta, Canada – roughly centred on the boomtown of Fort McMurray. These oil sands, hosted in the McMurray Formation, consist of a mixture of crude bitumen (a semi-solid form of crude oil), silica sand, clay minerals, and water. The Athabasca deposit is the largest known reservoir of crude bitumen in the world and the largest of three major oil sands deposits in Alberta, along with the nearby Peace River and Cold Lake deposits.

Together, these oil sand deposits lie under 141,000 square kilometres (54,000 sq mi) of boreal forest and muskeg (peat bogs) and contain about 1.7 trillion barrels (270×109 m3) of bitumen in-place, comparable in magnitude to the world’s total proven reserves of conventional petroleum. Although the former CEO of Shell Canada, Clive Mather, estimated Canada’s reserves to be 2 trillion barrels (320 km3) or more, the International Energy Agency (IEA) lists Canada’s reserves as being 178 billion barrels (2.83×1010 m3).

As for locating a carbon management organization in Calgary, it does make sense of a sort. Here’s a somewhat calmer description of Carbon Management Canada on the website’s About CMC page,

Carbon Management Canada CMC-NCE [Network Centre for Escellence] is a national network of academic researchers working with experts in the fossil energy industry, government, and the not-for-profit sector. Together, we are developing the technologies, the knowledge and the human capacity to radically reduce carbon dioxide emissions in the fossil energy industry and other large stationary emitters.

Carbon emissions and the growing global concern about its effects present a unique opportunity for innovation and collaboration, especially in the fossil energy industry. Rapidly increasing global complexity demands robust, responsive innovation that can only develop in a highly collaborative context involving industry, scientists, policy makers, politicians and industry leaders in concert with an informed, supportive public.

Carbon Management Canada is the national body charged with harnessing the collective energy of this diverse group in order to push forward an ambitious agenda of innovation and commercialization to bring research from the lab into the world of practice.

Funding

Funding for CMC was provided through the federal Networks of Centres of Excellence ($25 million) and the Province of Alberta through Alberta Environment ($25 million). Industry has also provided $5.7 million in contributions.

The Network has over 160 investigators at 27 Canadian academic institutions and close to 300 graduate and postdoctoral students working on research projects. CMC currently has invested $22 million in 44 research projects.

Our Themes

CMC is an interdisciplinary network with scientists working in fields that range from engineering to nanotechnology to geoscience to business to political science and communications. These investigators work in 4 themes: Recovery, Processing and Capture; Enabling and Emerging Technologies; Secure Carbon Storage; and Accelerating Appropriate Deployment of Low Carbon Emission Technologies.

Given that CMC is largely government-funded, it seems odd (almost as if they don’t want anyone to know) that the website does not feature a street address. In addition to trying a web search, you can find the information on the last page of the 2012 annual/financial report. One final note, the chair of CMC’s board is Gordon Lambert who is also Vice President, Sustainable Development, Suncor Energy. From Suncor’s About Us webpage,

n 1967, we pioneered commercial development of Canada’s oil sands — one of the largest petroleum resource basins in the world. Since then, Suncor has grown to become a globally competitive integrated energy company with a balanced portfolio of high-quality assets, a strong balance sheet and significant growth prospects. Across our operations, we intend to achieve production of one million barrels of oil equivalent per day.

Then, there’s this on the company’s home page,

We create energy for a better world

Suncor’s vision is to be trusted stewards of valuable natural resources. Guided by our values, we will lead the way to deliver economic prosperity, improved social well-being and a healthy environment for today and tomorrow.

The difficulty I’m highlighting is the number of competing interests. Governments which are dependent on industry for producing jobs and tax dollars are also funding ‘carbon management’. The fossil fuel-dependent industry make a great deal money from fossil fuels and doesn’t have much incentive to explore carbon management as that costs money and doesn’t add to profit. Regardless of how enlightened any individuals within that industry may be they have a fundamental problem similar to an asthmatic who’s being poisoned by the medication they need to breathe. Do you get immediate relief from the medication, i.e., breathe, or do you refuse the medication which causes damage years in the future and continue struggling for air?

All of these institutions (CMC, Suncor, etc.) would have more credibility if they addressed the difficulties rather than ignoring them.