A Jan. 13, 2017 news item on ScienceDaily announces a discovery about self-assembly of 102-atom gold nanoclusters,

Self-assembly of matter is one of the fundamental principles of nature, directing the growth of larger ordered and functional systems from smaller building blocks. Self-assembly can be observed in all length scales from molecules to galaxies. Now, researchers at the Nanoscience Centre of the University of Jyväskylä and the HYBER Centre of Excellence of Aalto University in Finland report a novel discovery of self-assembling two- and three-dimensional materials that are formed by tiny gold nanoclusters of just a couple of nanometres in size, each having 102 gold atoms and a surface layer of 44 thiol molecules. The study, conducted with funding from the Academy of Finland and the European Research Council, has been published in Angewandte Chemie.

A Jan. 13, 2017 Academy of Finland press release, which originated the news item, provides more technical information about the work,

The atomic structure of the 102-atom gold nanocluster was first resolved by the group of Roger D Kornberg at Stanford University in 2007 (2). Since then, several further studies of its properties have been conducted in the Jyväskylä Nanoscience Centre, where it has also been used for electron microscopy imaging of virus structures (3). The thiol surface of the nanocluster has a large number of acidic groups that can form directed hydrogen bonds to neighbouring nanoclusters and initiate directed self-assembly.

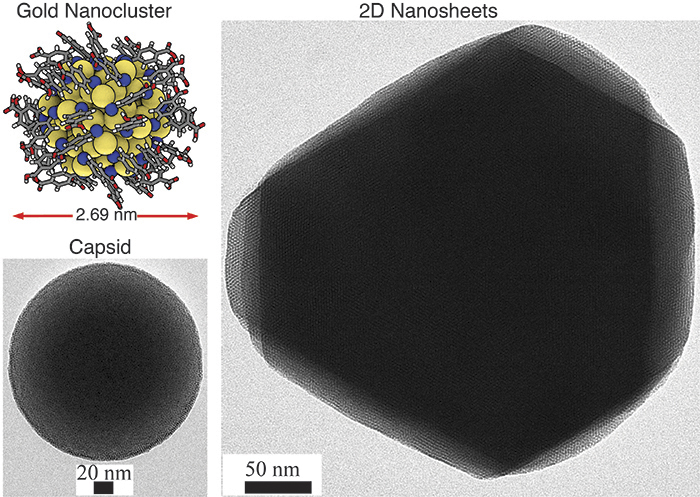

The self-assembly of gold nanoclusters took place in a water-methanol mixture and produced two distinctly different superstructures that were imaged in a high-resolution electron microscope at Aalto University. In one of the structures, two-dimensional hexagonally ordered layers of gold nanoclusters were stacked together, each layer being just one nanocluster thick. Modifying the synthesis conditions, also three-dimensional spherical, hollow capsid structures were observed, where the thickness of the capsid wall corresponds again to just one nanocluster size (see figure).

While the details of the formation mechanisms of these superstructures warrant further systemic investigations, the initial observations open several new views into synthetically made self-assembling nanomaterials.

“Today, we know of several tens of different types of atomistically precise gold nanoclusters, and I believe they can exhibit a wide variety of self-assembling growth patterns that could produce a range of new meta-materials,” said Academy Professor Hannu Häkkinen, who coordinated the research at the Nanoscience Centre. “In biology, typical examples of self-assembling functional systems are viruses and vesicles. Biological self-assembled structures can also be de-assembled by gentle changes in the surrounding biochemical conditions. It’ll be of great interest to see whether these gold-based materials can be de-assembled and then re-assembled to different structures by changing something in the chemistry of the surrounding solvent.”

“The free-standing two-dimensional nanosheets will bring opportunities towards new-generation functional materials, and the hollow capsids will pave the way for highly lightweight colloidal framework materials,” Postdoctoral Researcher Nonappa (Aalto University) said.

Professor Olli Ikkala of Aalto University said: “In a broader framework, it has remained as a grand challenge to master the self-assemblies through all length scales to tune the functional properties of materials in a rational way. So far, it has been commonly considered sufficient to achieve sufficiently narrow size distributions of the constituent nanoscale structural units to achieve well-defined structures. The present findings suggest a paradigm change to pursue strictly defined nanoscale units for self-assemblies.”

…

References:

(1) Nonappa, T. Lahtinen, J.S. Haataja, T.-R. Tero, H. Häkkinen and O. Ikkala, “Template-Free Supracolloidal Self-Assembly of Atomically Precise Gold Nanoclusters: From 2D Colloidal Crystals to Spherical Capsids”, Angewandte Chemie International Edition, published online 23 November 2016, DOI: 10.1002/anie.201609036

(2) P. Jadzinsky et al., “Structure of a thiol-monolayer protected gold nanoparticle at 1.1Å resolution”, Science 318, 430 (2007)

(3) V. Marjomäki et al., “Site-specific targeting of enterovirus capsid by functionalized monodispersed gold nanoclusters”, PNAS 111, 1277 (2014)

Here’s the figure mentioned in the news release,

Figure: 2D hexagonal sheet-like and 3D capsid structures based on atomically precise gold nanoclusters as guided by hydrogen bonding between the ligands. The inset in the top left corner shows the atomic structure of one gold nanocluster.

Here’s a link to and a citation for the paper,

Template-Free Supracolloidal Self-Assembly of Atomically Precise Gold Nanoclusters: From 2D Colloidal Crystals to Spherical Capsids by Dr. Nonappa, Dr. Tanja Lahtinen, M. Sc. Johannes. S. Haataja, Dr. Tiia-Riikka Tero, Prof. Hannu Häkkinen, and Prof. Olli Ikkala. Angewandte Chemie International Edition Volume 55, Issue 52, pages 16035–16038, December 23, 2016 Version of Record online: 23 NOV 2016 DOI: 10.1002/anie.201609036

© 2016 Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

This paper is behind a paywall.