Whoever wrote the headline for an Aug. 1, 2016 article about our nanotechnology-enabled future by Jason Lam (headlines are not always written by the author) for South China Morning Post had some fun with words, “Scientists are flushed with success: sunshine to replace the need to wash clothes, while toilets will no longer need water,” (Note: A link has been removed)

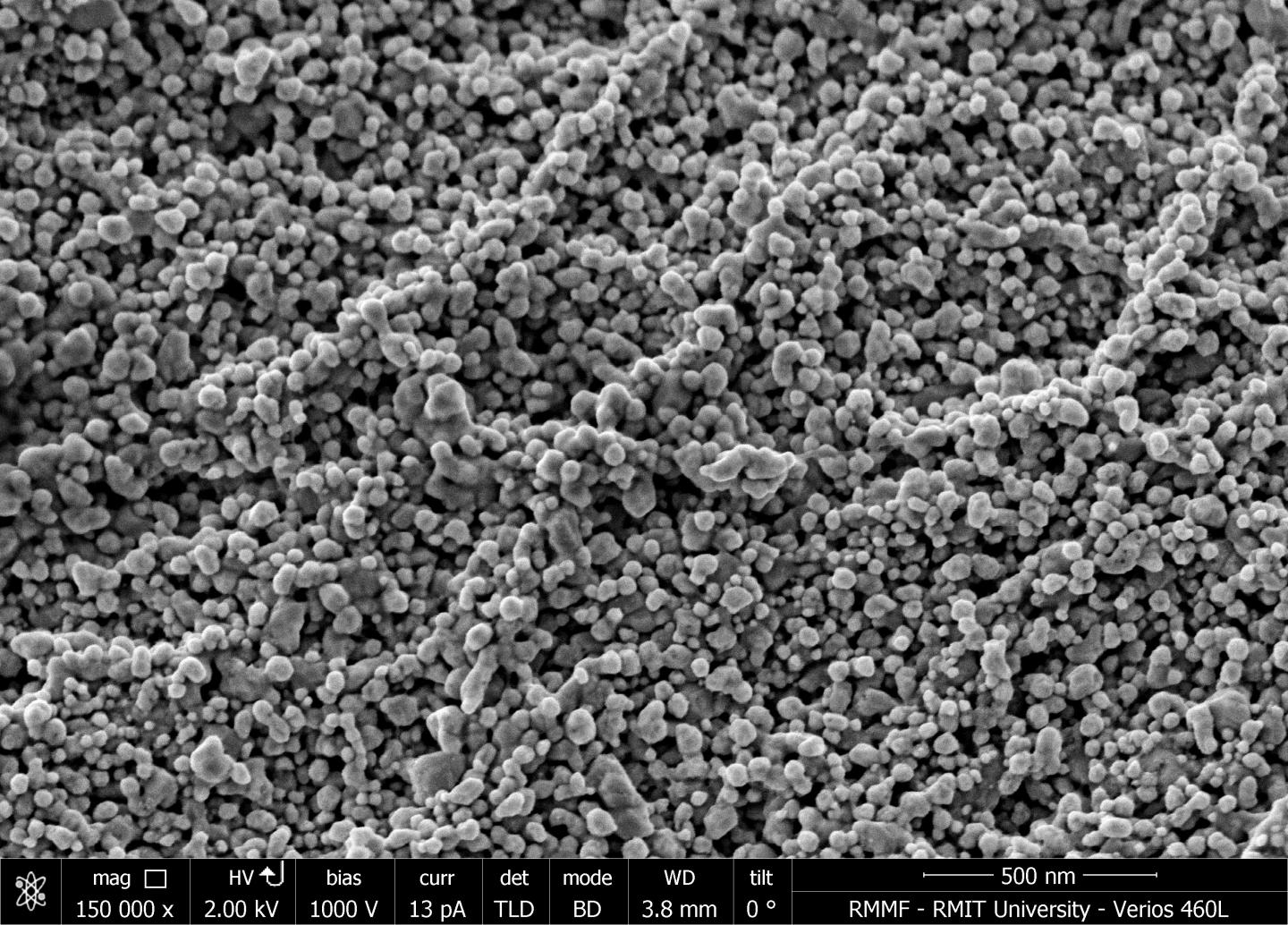

Self-cleaning textiles are being explored at RMIT University in Melbourne, Australia. In this pioneering technology, researchers have been growing nanostructures on cotton fabric which, when exposed to light, release a burst of energy that then degrades organic matter. So a little ray or sunshine – or even a light bulb – could, in effect, clean your clothes for you.

As the scientists explain it, the nanostructure is metal-based, so it can absorb visible light. This creates energy, which is able to degrade organic matter on which it is present [the textile], “so that’s how it’ll get rid of stains”.

Tests on stains have proven promising, say the scientists, with results achieved within between six and 30 minutes of light exposure, depending on the material. The research is now moving on to sweat testing.

…

Stain-free fabrics have been around for a while, but they haven’t felt as comfortable as traditional textiles. Dropel Fabrics, a creator of hydrophobic natural textiles, is working to overcome that. It has developed a patented nanotechnology process infuses cotton fibres with water, stain, and odour repellent properties, while maintaining, the company says, the textile’s softness and breathability.

Apparently, it involves a “simple process” which encapsulates polymers within the textile fibres, and creates a protective layer. Invisible to the hand and eye, this protective layer does not affect the fabric’s texture, so its softness and construction is maintained. The company says it is exploring partnerships with high-end fashion brands.

…

Two Mexican industrial designers are working on their own solution for a waterless toilet, this time designed for urban areas. Reasoning that even some apartment dwellers have no access to sewage, their concept turns human waste into greywater which can safely be disposed of down the household drain.

…

I’m glad to have found Lam’s article as getting the perspective from Asia helps to balance this US-, Canada-, Euro-, and UK-centric science blog.