An April 4, 2014 news item on Azonano describes some nanotube research at the University of Florida that reaches past carbon to a new kind of nanotube,

Researchers with the University of Florida’s [UF] Institute of Food and Agricultural Sciences took what some would consider garbage and made a remarkable scientific tool, one that could someday help to correct genetic disorders or treat cancer without chemotherapy’s nasty side effects.

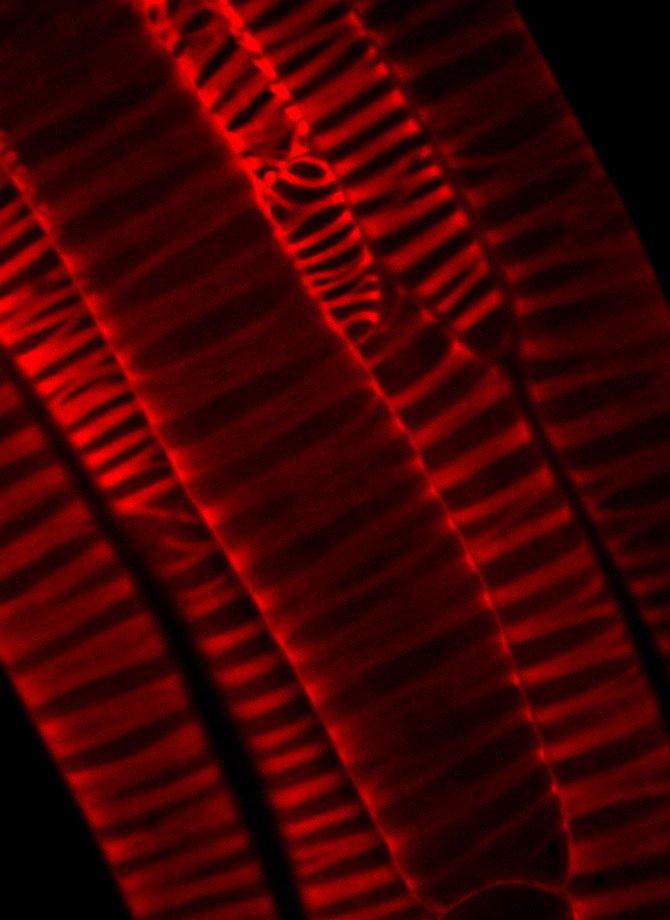

Wilfred Vermerris, an associate professor in UF’s department of microbiology and cell science, and Elena Ten, a postdoctoral research associate, created from plant waste a novel nanotube, one that is much more flexible than rigid carbon nanotubes currently used. The researchers say the lignin nanotubes – about 500 times smaller than a human eyelash – can deliver DNA directly into the nucleus of human cells in tissue culture, where this DNA could then correct genetic conditions. Experiments with DNA injection are currently being done with carbon nanotubes, as well.

“That was a surprising result,” Vermerris said. “If you can do this in actual human beings you could fix defective genes that cause disease symptoms and replace them with functional DNA delivered with these nanotubes.”

An April 3, 2014 University of Florida’s Institute of Food and Agricultural Sciences news release, which originated the news item, describes the lignin nanotubes (LNTs) and future applications in more detail,

The nanotube is made up of lignin from plant material obtained from a UF biofuel pilot facility in Perry, Fla. Lignin is an integral part of the secondary cell walls of plants and enables water movement from the roots to the leaves, but it is not used to make biofuels and would otherwise be burned to generate heat or electricity at the biofuel plant. The lignin nanotubes can be made from a variety of plant residues, including sorghum, poplar, loblolly pine and sugar cane. [emphasis mine]

The researchers first tested to see if the nanotubes were toxic to human cells and were surprised to find that they were less so than carbon nanotubes. Thus, they could deliver a higher dose of medicine to the human cell tissue. Then they researched if the nanotubes could deliver plasmid DNA to the same cells and that was successful, too. A plasmid is a small DNA molecule that is physically separate from, and can replicate independently of, chromosomal DNA within a cell.

“It’s not a very smooth road because we had to try different experiments to confirm the results,” Ten said. “But it was very fruitful.”

In cases of genetic disorders, the nanotube would be loaded with a functioning copy of a gene, and injected into the body, where it would target the affected tissue, which then makes the missing protein and corrects the genetic disorder.

Although Vermerris cautioned that treatment in humans is many years away, among the conditions that these gene-carrying nanotubes could correct include cystic fibrosis and muscular dystrophy. But, he added, that patients would have to take the corrective DNA via nanotubes on a continuing basis.

Another application under consideration is to use the lignin nanotubes for the delivery of chemotherapy drugs in cancer patients. The nanotubes would ensure the drugs only get to the tumor without affecting healthy tissues.

Vermerris said they created different types of nanotubes, depending on the experiment. They could also adapt nanotubes to a patient’s specific needs, a process called customization.

“You can think about it as a chest of drawers and, depending on the application, you open one drawer or use materials from a different drawer to get things just right for your specific application,” he said. “It’s not very difficult to do the customization.”

The next step in the research process is for Vermerris and Ten to begin experiments on mice. They are in the application process for those experiments, which would take several years to complete. If those are successful, permits would need to be obtained for their medical school colleagues to conduct research on human patients, with Vermerris and Ten providing the nanotubes for that research.

“We are a long way from that point,” Vermerris said. “That’s the optimistic long-term trajectory.”

I hope they have good luck with this work. I have emphasized the plant waste the University of Florida scientists studied due to the inclusion of poplar, which is featured in the University of British Columbia research work also being mentioned in this post.

Getting back to Florida for a moment, here’s a link to and a citation for the paper,

Lignin Nanotubes As Vehicles for Gene Delivery into Human Cells by Elena Ten, Chen Ling, Yuan Wang, Arun Srivastava, Luisa Amelia Dempere, and Wilfred Vermerris. Biomacromolecules, 2014, 15 (1), pp 327–338 DOI: 10.1021/bm401555p Publication Date (Web): December 5, 2013

Copyright © 2013 American Chemical Society

This is an open access paper.

Meanwhile, researchers at the University of British Columbia (UBC) are trying to limit the amount of lignin in trees (specifically poplars, which are not mentioned in this excerpt but in the next). From an April 3, 2014 UBC news release,

Researchers have genetically engineered trees that will be easier to break down to produce paper and biofuel, a breakthrough that will mean using fewer chemicals, less energy and creating fewer environmental pollutants.

“One of the largest impediments for the pulp and paper industry as well as the emerging biofuel industry is a polymer found in wood known as lignin,” says Shawn Mansfield, a professor of Wood Science at the University of British Columbia.

Lignin makes up a substantial portion of the cell wall of most plants and is a processing impediment for pulp, paper and biofuel. Currently the lignin must be removed, a process that requires significant chemicals and energy and causes undesirable waste.

Researchers used genetic engineering to modify the lignin to make it easier to break down without adversely affecting the tree’s strength.

“We’re designing trees to be processed with less energy and fewer chemicals, and ultimately recovering more wood carbohydrate than is currently possible,” says Mansfield.

Researchers had previously tried to tackle this problem by reducing the quantity of lignin in trees by suppressing genes, which often resulted in trees that are stunted in growth or were susceptible to wind, snow, pests and pathogens.

“It is truly a unique achievement to design trees for deconstruction while maintaining their growth potential and strength.”

The study, a collaboration between researchers at the University of British Columbia, the University of Wisconsin-Madison, Michigan State University, is a collaboration funded by Great Lakes Bioenergy Research Center, was published today in Science.

Here’s more about lignin and how a decrease would free up more material for biofuels in a more environmentally sustainable fashion, from the news release,

The structure of lignin naturally contains ether bonds that are difficult to degrade. Researchers used genetic engineering to introduce ester bonds into the lignin backbone that are easier to break down chemically.

The new technique means that the lignin may be recovered more effectively and used in other applications, such as adhesives, insolation, carbon fibres and paint additives.

Genetic modification

The genetic modification strategy employed in this study could also be used on other plants like grasses to be used as a new kind of fuel to replace petroleum.

Genetic modification can be a contentious issue, but there are ways to ensure that the genes do not spread to the forest. These techniques include growing crops away from native stands so cross-pollination isn’t possible; introducing genes to make both the male and female trees or plants sterile; and harvesting trees before they reach reproductive maturity.

In the future, genetically modified trees could be planted like an agricultural crop, not in our native forests. Poplar is a potential energy crop for the biofuel industry because the tree grows quickly and on marginal farmland. [emphasis mine] Lignin makes up 20 to 25 per cent of the tree.

“We’re a petroleum reliant society,” says Mansfield. “We rely on the same resource for everything from smartphones to gasoline. We need to diversify and take the pressure off of fossil fuels. Trees and plants have enormous potential to contribute carbon to our society.”

As noted earlier, the researchers in Florida mention poplars in their paper (Note: Links have been removed),

Gymnosperms such as loblolly pine (Pinus taeda L.) contain lignin that is composed almost exclusively of G-residues, whereas lignin from angiosperm dicots, including poplar (Populus spp.) contains a mixture of G- and S-residues. [emphasis mine] Due to the radical-mediated addition of monolignols to the growing lignin polymer, lignin contains a variety of interunit bonds, including aryl–aryl, aryl–alkyl, and alkyl–alkyl bonds.(3) This feature, combined with the association between lignin and cell-wall polysaccharides, which involves both physical and chemical interactions, make the isolation of lignin from plant cell walls challenging. Various isolation methods exist, each relying on breaking certain types of chemical bonds within the lignin, and derivatizations to solubilize the resulting fragments.(5) Several of these methods are used on a large scale in pulp and paper mills and biorefineries, where lignin needs to be removed from woody biomass and crop residues(6) in order to use the cellulose for the production of paper, biofuels, and biobased polymers. The lignin is present in the waste stream and has limited intrinsic economic value.(7)

Since hydroxyl and carboxyl groups in lignin facilitate functionalization, its compatibility with natural and synthetic polymers for different commercial applications have been extensively studied.(8-12) One of the promising directions toward the cost reduction associated with biofuel production is the use of lignin for low-cost carbon fibers.(13) Other recent studies reported development and characterization of lignin nanocomposites for multiple value-added applications. For example, cellulose nanocrystals/lignin nanocomposites were developed for improved optical, antireflective properties(14, 15) and thermal stability of the nanocomposites.(16) [emphasis mine] Model ultrathin bicomponent films prepared from cellulose and lignin derivatives were used to monitor enzyme binding and cellulolytic reactions for sensing platform applications.(17) Enzymes/“synthetic lignin” (dehydrogenation polymer (DHP)) interactions were also investigated to understand how lignin impairs enzymatic hydrolysis during the biomass conversion processes.(18)

The synthesis of lignin nanotubes and nanowires was based on cross-linking a lignin base layer to an alumina membrane, followed by peroxidase-mediated addition of DHP and subsequent dissolution of the membrane in phosphoric acid.(1) Depending upon monomers used for the deposition of DHP, solid nanowires, or hollow nanotubes could be manufactured and easily functionalized due to the presence of many reactive groups. Due to their autofluorescence, lignin nanotubes permit label-free detection under UV radiation.(1) These features make lignin nanotubes suitable candidates for numerous biomedical applications, such as the delivery of therapeutic agents and DNA to specific cells.

…

The synthesis of LNTs in a sacrificial template membrane is not limited to a single source of lignin or a single lignin isolation procedure. Dimensions of the LNTs and their cytotoxicity to HeLa cells appear to be determined primarily by the lignin isolation procedure, whereas the transfection efficiency is also influenced by the source of the lignin (plant species and genotype). This means that LNTs can be tailored to the application for which they are intended. [emphasis mine] The ability to design LNTs for specific purposes will benefit from a more thorough understanding of the relationship between the structure and the MW of the lignin used to prepare the LNTs, the nanomechanical properties, and the surface characteristics.

We have shown that DNA is physically associated with the LNTs and that the LNTs enter the cytosol, and in some case the nucleus. The LNTs made from NaOH-extracted lignin are of special interest, as they were the shortest in length, substantially reduced HeLa cell viability at levels above approximately 50 mg/mL, and, in the case of pine and poplar, were the most effective in the transfection [penetrating the cell with a bacterial plasmid to leave genetic material in this case] experiments. [emphasis mine]

As I see the issues presented with these two research efforts, there are environmental and energy issues with extracting the lignin while there seem to be some very promising medical applications possible with lignin ‘waste’. These two research efforts aren’t necessarily antithetical but they do raise some very interesting issues as to how we approach our use of resources and future policies.

ETA May 16, 2014: The beat goes on with the Georgia (US) Institute of Technology issues a roadmap for making money from lignin. From a Georgia Tech May 15, 2014 news release on EurekAlert,

When making cellulosic ethanol from plants, one problem is what to do with a woody agricultural waste product called lignin. The old adage in the pulp industry has been that one can make anything from lignin except money.

A new review article in the journal Science points the way toward a future where lignin is transformed from a waste product into valuable materials such as low-cost carbon fiber for cars or bio-based plastics. Using lignin in this way would create new markets for the forest products industry and make ethanol-to-fuel conversion more cost-effective.

“We’ve developed a roadmap for integrating genetic engineering with analytical chemistry tools to tailor the structure of lignin and its isolation so it can be used for materials, chemicals and fuels,” said Arthur Ragauskas, a professor in the School of Chemistry and Biochemistry at the Georgia Institute of Technology. Ragauskas is also part of the Institute for Paper Science and Technology at Georgia Tech.

The roadmap was published May 15 [2014] in the journal Science. …

Here’s a link to and citation for the ‘roadmap’,

Lignin Valorization: Improving Lignin Processing in the Biorefinery by Arthur J. Ragauskas, Gregg T. Beckham, Mary J. Biddy, Richard Chandra, Fang Chen, Mark F. Davis, Brian H. Davison, Richard A. Dixon, Paul Gilna, Martin Keller, Paul Langan, Amit K. Naskar, Jack N. Saddler, Timothy J. Tschaplinski, Gerald A. Tuskan, and Charles E. Wyman. Science 16 May 2014: Vol. 344 no. 6185 DOI: 10.1126/science.1246843

This paper is behind a paywall.