I’ve been meaning to get to this news item from late 2019 as it features work from a team that I’ve been following for a number of years now. First mentioned here in an October 17, 2011 posting, James Gimzewski has been working with researchers at the University of California at Los Angeles (UCLA) and researchers at Japan’s National Institute for Materials Science (NIMS) on neuromorphic computing.

This particular research had a protracted rollout with the paper being published in October 2019 and the last news item about it being published in mid-December 2019.

A December 17, 2029 news item on Nanowerk was the first to alert me to this new work (Note: A link has been removed),

UCLA scientists James Gimzewski and Adam Stieg are part of an international research team that has taken a significant stride toward the goal of creating thinking machines.

Led by researchers at Japan’s National Institute for Materials Science, the team created an experimental device that exhibited characteristics analogous to certain behaviors of the brain — learning, memorization, forgetting, wakefulness and sleep. The paper, published in Scientific Reports (“Emergent dynamics of neuromorphic nanowire networks”), describes a network in a state of continuous flux.

…

A December 16, 2019 UCLA news release, which originated the news item, offers more detail (Note: A link has been removed),

“This is a system between order and chaos, on the edge of chaos,” said Gimzewski, a UCLA distinguished professor of chemistry and biochemistry, a member of the California NanoSystems Institute at UCLA and a co-author of the study. “The way that the device constantly evolves and shifts mimics the human brain. It can come up with different types of behavior patterns that don’t repeat themselves.”

The research is one early step along a path that could eventually lead to computers that physically and functionally resemble the brain — machines that may be capable of solving problems that contemporary computers struggle with, and that may require much less power than today’s computers do.

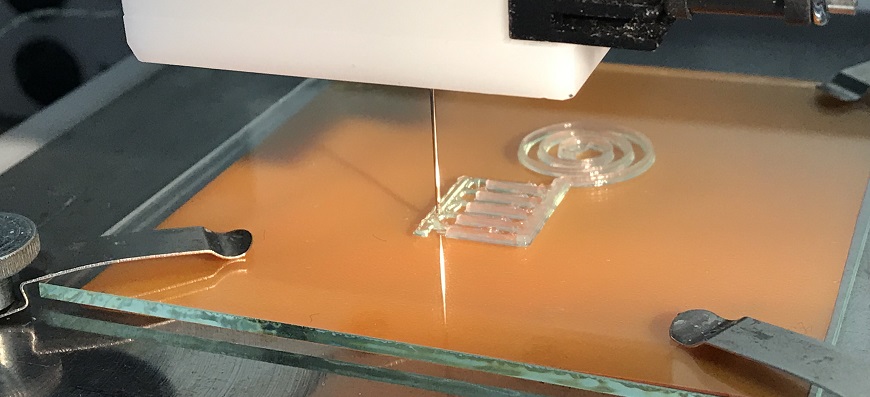

The device the researchers studied is made of a tangle of silver nanowires — with an average diameter of just 360 nanometers. (A nanometer is one-billionth of a meter.) The nanowires were coated in an insulating polymer about 1 nanometer thick. Overall, the device itself measured about 10 square millimeters — so small that it would take 25 of them to cover a dime.

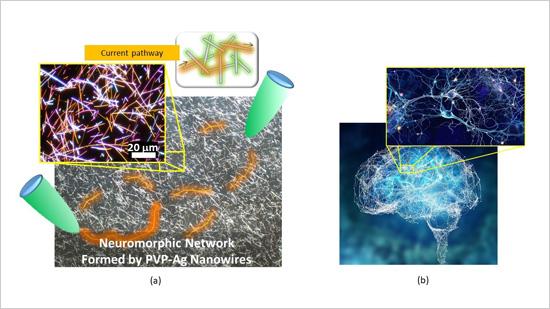

Allowed to randomly self-assemble on a silicon wafer, the nanowires formed highly interconnected structures that are remarkably similar to those that form the neocortex, the part of the brain involved with higher functions such as language, perception and cognition.

One trait that differentiates the nanowire network from conventional electronic circuits is that electrons flowing through them cause the physical configuration of the network to change. In the study, electrical current caused silver atoms to migrate from within the polymer coating and form connections where two nanowires overlap. The system had about 10 million of these junctions, which are analogous to the synapses where brain cells connect and communicate.

The researchers attached two electrodes to the brain-like mesh to profile how the network performed. They observed “emergent behavior,” meaning that the network displayed characteristics as a whole that could not be attributed to the individual parts that make it up. This is another trait that makes the network resemble the brain and sets it apart from conventional computers.

After current flowed through the network, the connections between nanowires persisted for as much as one minute in some cases, which resembled the process of learning and memorization in the brain. Other times, the connections shut down abruptly after the charge ended, mimicking the brain’s process of forgetting.

In other experiments, the research team found that with less power flowing in, the device exhibited behavior that corresponds to what neuroscientists see when they use functional MRI scanning to take images of the brain of a sleeping person. With more power, the nanowire network’s behavior corresponded to that of the wakeful brain.

The paper is the latest in a series of publications examining nanowire networks as a brain-inspired system, an area of research that Gimzewski helped pioneer along with Stieg, a UCLA research scientist and an associate director of CNSI.

“Our approach may be useful for generating new types of hardware that are both energy-efficient and capable of processing complex datasets that challenge the limits of modern computers,” said Stieg, a co-author of the study.

The borderline-chaotic activity of the nanowire network resembles not only signaling within the brain but also other natural systems such as weather patterns. That could mean that, with further development, future versions of the device could help model such complex systems.

In other experiments, Gimzewski and Stieg already have coaxed a silver nanowire device to successfully predict statistical trends in Los Angeles traffic patterns based on previous years’ traffic data.

Because of their similarities to the inner workings of the brain, future devices based on nanowire technology could also demonstrate energy efficiency like the brain’s own processing. The human brain operates on power roughly equivalent to what’s used by a 20-watt incandescent bulb. By contrast, computer servers where work-intensive tasks take place — from training for machine learning to executing internet searches — can use the equivalent of many households’ worth of energy, with the attendant carbon footprint.

“In our studies, we have a broader mission than just reprogramming existing computers,” Gimzewski said. “Our vision is a system that will eventually be able to handle tasks that are closer to the way the human being operates.”

The study’s first author, Adrian Diaz-Alvarez, is from the International Center for Material Nanoarchitectonics at Japan’s National Institute for Materials Science. Co-authors include Tomonobu Nakayama and Rintaro Higuchi, also of NIMS; and Zdenka Kuncic at the University of Sydney in Australia.

A November 11, 2019 National Institute for Materials Science (Japan) press release (also on EurekAlert but dated December 25, 2019) first announced the news,

An international joint research team led by NIMS succeeded in fabricating a neuromorphic network composed of numerous metallic nanowires. Using this network, the team was able to generate electrical characteristics similar to those associated with higher order brain functions unique to humans, such as memorization, learning, forgetting, becoming alert and returning to calm. The team then clarified the mechanisms that induced these electrical characteristics.

The development of artificial intelligence (AI) techniques has been rapidly advancing in recent years and has begun impacting our lives in various ways. Although AI processes information in a manner similar to the human brain, the mechanisms by which human brains operate are still largely unknown. Fundamental brain components, such as neurons and the junctions between them (synapses), have been studied in detail. However, many questions concerning the brain as a collective whole need to be answered. For example, we still do not fully understand how the brain performs such functions as memorization, learning and forgetting, and how the brain becomes alert and returns to calm. In addition, live brains are difficult to manipulate in experimental research. For these reasons, the brain remains a “mysterious organ.” A different approach to brain research?in which materials and systems capable of performing brain-like functions are created and their mechanisms are investigated?may be effective in identifying new applications of brain-like information processing and advancing brain science.

The joint research team recently built a complex brain-like network by integrating numerous silver (Ag) nanowires coated with a polymer (PVP) insulating layer approximately 1 nanometer in thickness. A junction between two nanowires forms a variable resistive element (i.e., a synaptic element) that behaves like a neuronal synapse. This nanowire network, which contains a large number of intricately interacting synaptic elements, forms a “neuromorphic network”. When a voltage was applied to the neuromorphic network, it appeared to “struggle” to find optimal current pathways (i.e., the most electrically efficient pathways). The research team measured the processes of current pathway formation, retention and deactivation while electric current was flowing through the network and found that these processes always fluctuate as they progress, similar to the human brain’s memorization, learning, and forgetting processes. The observed temporal fluctuations also resemble the processes by which the brain becomes alert or returns to calm. Brain-like functions simulated by the neuromorphic network were found to occur as the huge number of synaptic elements in the network collectively work to optimize current transport, in the other words, as a result of self-organized and emerging dynamic processes..

The research team is currently developing a brain-like memory device using the neuromorphic network material. The team intends to design the memory device to operate using fundamentally different principles than those used in current computers. For example, while computers are currently designed to spend as much time and electricity as necessary in pursuit of absolutely optimum solutions, the new memory device is intended to make a quick decision within particular limits even though the solution generated may not be absolutely optimum. The team also hopes that this research will facilitate understanding of the brain’s information processing mechanisms.

This project was carried out by an international joint research team led by Tomonobu Nakayama (Deputy Director, International Center for Materials Nanoarchitectonics (WPI-MANA), NIMS), Adrian Diaz Alvarez (Postdoctoral Researcher, WPI-MANA, NIMS), Zdenka Kuncic (Professor, School of Physics, University of Sydney, Australia) and James K. Gimzewski (Professor, California NanoSystems Institute, University of California Los Angeles, USA).

Here at last is a link to and a citation for the paper,

Emergent dynamics of neuromorphic nanowire networks by Adrian Diaz-Alvarez, Rintaro Higuchi, Paula Sanz-Leon, Ido Marcus, Yoshitaka Shingaya, Adam Z. Stieg, James K. Gimzewski, Zdenka Kuncic & Tomonobu Nakayama. Scientific Reports volume 9, Article number: 14920 (2019) DOI: https://doi.org/10.1038/s41598-019-51330-6 Published: 17 October 2019

This paper is open access.