There’s a very good November 11, 2019 article by Natalie Angier for the New York Times on carbon nanotubes (CNTs) and the colour black,

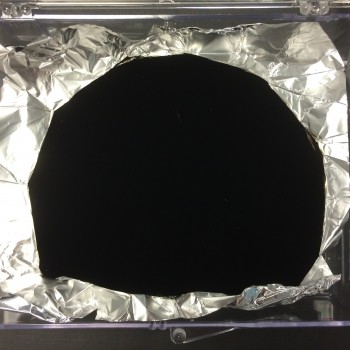

On a laboratory bench at the National Institute of Standards and Technology was a square tray with two black disks inside, each about the width of the top of a Dixie cup. Both disks were undeniably black, yet they didn’t look quite the same.

Solomon Woods, 49, a trim, dark-haired, soft-spoken physicist, was about to demonstrate how different they were, and how serenely voracious a black could be.

“The human eye is extraordinarily sensitive to light,” Dr. Woods said. Throw a few dozen photons its way, a few dozen quantum-sized packets of light, and the eye can readily track them.

Dr. Woods pulled a laser pointer from his pocket. “This pointer,” he said, “puts out 100 trillion photons per second.” He switched on the laser and began slowly sweeping its bright beam across the surface of the tray.

On hitting the white background, the light bounced back almost unimpeded, as rude as a glaring headlight in a rearview mirror.

The beam moved to the first black disk, a rondel of engineered carbon now more than a decade old. The light dimmed significantly, as a sizable tranche of the incident photons were absorbed by the black pigment, yet the glow remained surprisingly strong.

Finally Dr. Woods trained his pointer on the second black disk, and suddenly the laser’s brilliant beam, its brash photonic probe, simply — disappeared. Trillions of light particles were striking the black disk, and virtually none were winking back up again. It was like watching a circus performer swallow a sword, or a husband “share” your plate of French fries: Hey, where did it all go?

N.I.S.T. disk number two was an example of advanced ultra-black technology: elaborately engineered arrays of tiny carbon cylinders, or nanotubes, designed to capture and muzzle any light they encounter. Blacker is the new black, and researchers here and abroad are working to create ever more efficient light traps, which means fabricating materials that look ever darker, ever flatter, ever more ripped from the void.

The N.I.S.T. ultra-black absorbs at least 99.99 percent of the light that stumbles into its nanotube forest. But scientists at the Massachusetts Institute of Technology reported in September the creation of a carbon nanotube coating that they claim captures better than 99.995 of the incident light.

…

… The more fastidious and reliable the ultra-black, the more broadly useful it will prove to be — in solar power generators, radiometers, industrial baffles and telescopes primed to detect the faintest light fluxes as a distant planet traverses the face of its star.

Psychology and metaphors

It’s not all technical, Angier goes on to mention the psychological and metaphorical aspects,

Psychologists have gathered evidence that black is among the most metaphorically loaded of all colors, and that we absorb our often contradictory impressions about black at a young age.

Reporting earlier this year in the Quarterly Journal of Experimental Psychology, Robin Kramer and Joanne Prior of the University of Lincoln in the United Kingdom compared color associations in a group of 104 children, aged 5 to 10, with those of 100 university students.

The researchers showed subjects drawings in which a lineup of six otherwise identical images differed only in some aspect of color. The T-shirt of a boy taking a test, for example, was switched from black to blue to green to red to white to yellow. The same for a businessman’s necktie, a schoolgirl’s dress, a dog’s collar, a boxer’s gloves.

Participants were asked to link images with traits. Which boy was likeliest to cheat on the test? Which man was likely to be in charge at work? Which girl was the smartest in her class, which dog the scariest?

Again and again, among both children and young adults, black pulled ahead of nearly every color but red. Black was the color of cheating, and black was the color of cleverness. A black tie was the mark of a boss, a black collar the sign of a pit bull. Black was the color of strength and of winning. Black was the color of rage.

…

Art

Then, there is the world of art,

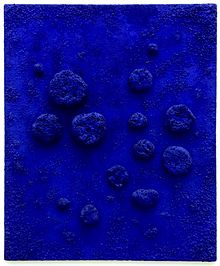

For artists, black is basal and nonnegotiable, the source of shadow, line, volume, perspective and mood. “There is a black which is old and a black which is fresh,” Ad Reinhardt, the abstract expressionist artist, said. “Lustrous black and dull black, black in sunlight and black in shadow.”

So essential is black to any aesthetic act that, as David Scott Kastan and Stephen Farthing describe in their scholarly yet highly entertaining book, “On Color,” modern artists have long squabbled over who pioneered the ultimate visual distillation: the all-black painting.

Was it the Russian Constructivist Aleksandr Rodchenko, who in 1918 created a series of eight seemingly all-black canvases? No, insisted the American artist Barnett Newman: Those works were very dark brown, not black. He, Mr. Newman, deserved credit for his 1949 opus, “Abraham,” which in 1966 he described as “the first and still the only black painting in history.”

But what about Kazimir Malevich’s “Black Square” of 1915? True, it was a black square against a white background, but the black part was the point. Then again, the English polymath Robert Fludd had engraved a black square in a white border back in 1617.

Clearly, said Alfred H. Barr, Jr., the first director of the Museum of Modern Art, “Each generation must paint its own black square.”

…

Structural colour

Solomon and his NIST colleagues and the MIT scientists are all trying to create materials with structural colour, in this case, black. Angier goes on to discuss structural colour in nature mentioning bird feathers and spiders as examples of where you might find superblacks. For anyone unfamiliar with structural colour, the colour is not achieved with pigment or dye but with tiny structures, usually measured at the nanoscale, on a bird’s wing, a spider’s belly, a plant leaf, etc. Structural colour does not fade or change . Still, it’s possible to destroy the structures, i.e., the colour, but light and time will not have any effect since it’s the tiny structures and their optical properties which are producing the colour . (Even after all these years, my favourite structural colour story remains a Feb. 1, 2013 article, Color from Structure, by Cristina Luiggi for The Scientist magazine. For a shorter version, I excerpted parts of Luiggi’s story for my February 7, 2013 posting.)

The examples of structural colour in Angier’s article were new to me. However, there are many, many examples elsewhere,. You can find some here by using the terms ‘structural colour’ or ‘structural color’ in the blog’s search engine.

Angier’s is a really good article and I strongly recommend reading it if you have time but I’m a little surprised she doesn’t mention Vantablack and the artistic feud. More about that in a moment,

Massachusetts Institute of Technology and a ‘blacker black’

According to MIT (Massachusetts Institute of Technology), they have the blackest black. It too is courtesy of carbon nanotubes.

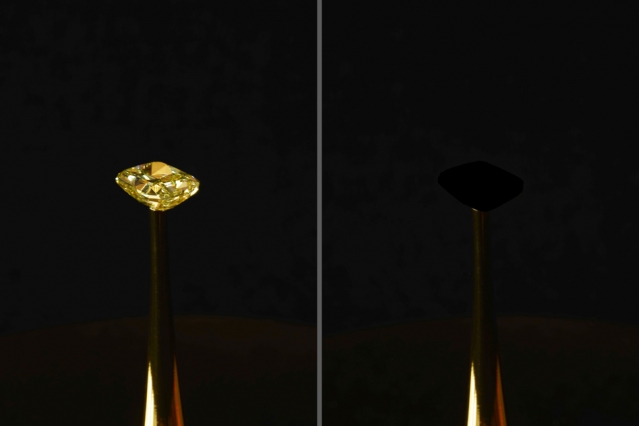

What you see in the above ‘The Redemption of Vanity’ was on show at the New York Stock Exchange (NYSE) from September 13 – November 29, 2019. It’s both an art piece and a demonstration of MIT’s blackest black.

There are two new releases from MIT. The first is the more technical one. From a Sept. 12, 2019 MIT news release,

With apologies to “Spinal Tap,” it appears that black can, indeed, get more black.

MIT engineers report today that they have cooked up a material that is 10 times blacker than anything that has previously been reported. The material is made from vertically aligned carbon nanotubes, or CNTs — microscopic filaments of carbon, like a fuzzy forest of tiny trees, that the team grew on a surface of chlorine-etched aluminum foil. The foil captures at least 99.995 percent* of any incoming light, making it the blackest material on record.

The researchers have published their findings today in the journal ACS-Applied Materials and Interfaces. They are also showcasing the cloak-like material as part of a new exhibit today at the New York Stock Exchange, titled “The Redemption of Vanity.”

The artwork, conceived by Diemut Strebe, an artist-in-residence at the MIT Center for Art, Science, and Technology, in collaboration with Brian Wardle, professor of aeronautics and astronautics at MIT, and his group, and MIT Center for Art, Science, and Technology artist-in-residence Diemut Strebe, features a 16.78-carat natural yellow diamond from LJ West Diamonds, estimated to be worth $2 million, which the team coated with the new, ultrablack CNT material. The effect is arresting: The gem, normally brilliantly faceted, appears as a flat, black void.

Wardle says the CNT material, aside from making an artistic statement, may also be of practical use, for instance in optical blinders that reduce unwanted glare, to help space telescopes spot orbiting exoplanets.

“There are optical and space science applications for very black materials, and of course, artists have been interested in black, going back well before the Renaissance,” Wardle says. “Our material is 10 times blacker than anything that’s ever been reported, but I think the blackest black is a constantly moving target. Someone will find a blacker material, and eventually we’ll understand all the underlying mechanisms, and will be able to properly engineer the ultimate black.”

Wardle’s co-author on the paper is former MIT postdoc Kehang Cui, now a professor at Shanghai Jiao Tong University.

Into the void

Wardle and Cui didn’t intend to engineer an ultrablack material. Instead, they were experimenting with ways to grow carbon nanotubes on electrically conducting materials such as aluminum, to boost their electrical and thermal properties.

But in attempting to grow CNTs on aluminum, Cui ran up against a barrier, literally: an ever-present layer of oxide that coats aluminum when it is exposed to air. This oxide layer acts as an insulator, blocking rather than conducting electricity and heat. As he cast about for ways to remove aluminum’s oxide layer, Cui found a solution in salt, or sodium chloride.

At the time, Wardle’s group was using salt and other pantry products, such as baking soda and detergent, to grow carbon nanotubes. In their tests with salt, Cui noticed that chloride ions were eating away at aluminum’s surface and dissolving its oxide layer.

“This etching process is common for many metals,” Cui says. “For instance, ships suffer from corrosion of chlorine-based ocean water. Now we’re using this process to our advantage.”

Cui found that if he soaked aluminum foil in saltwater, he could remove the oxide layer. He then transferred the foil to an oxygen-free environment to prevent reoxidation, and finally, placed the etched aluminum in an oven, where the group carried out techniques to grow carbon nanotubes via a process called chemical vapor deposition.

By removing the oxide layer, the researchers were able to grow carbon nanotubes on aluminum, at much lower temperatures than they otherwise would, by about 100 degrees Celsius. They also saw that the combination of CNTs on aluminum significantly enhanced the material’s thermal and electrical properties — a finding that they expected.

What surprised them was the material’s color.

“I remember noticing how black it was before growing carbon nanotubes on it, and then after growth, it looked even darker,” Cui recalls. “So I thought I should measure the optical reflectance of the sample.

“Our group does not usually focus on optical properties of materials, but this work was going on at the same time as our art-science collaborations with Diemut, so art influenced science in this case,” says Wardle.

Wardle and Cui, who have applied for a patent on the technology, are making the new CNT process freely available to any artist to use for a noncommercial art project.

“Built to take abuse”

Cui measured the amount of light reflected by the material, not just from directly overhead, but also from every other possible angle. The results showed that the material absorbed at least 99.995 percent of incoming light, from every angle. In other words, it reflected 10 times less light than all other superblack materials, including Vantablack. If the material contained bumps or ridges, or features of any kind, no matter what angle it was viewed from, these features would be invisible, obscured in a void of black.

The researchers aren’t entirely sure of the mechanism contributing to the material’s opacity, but they suspect that it may have something to do with the combination of etched aluminum, which is somewhat blackened, with the carbon nanotubes. Scientists believe that forests of carbon nanotubes can trap and convert most incoming light to heat, reflecting very little of it back out as light, thereby giving CNTs a particularly black shade.

“CNT forests of different varieties are known to be extremely black, but there is a lack of mechanistic understanding as to why this material is the blackest. That needs further study,” Wardle says.

The material is already gaining interest in the aerospace community. Astrophysicist and Nobel laureate John Mather, who was not involved in the research, is exploring the possibility of using Wardle’s material as the basis for a star shade — a massive black shade that would shield a space telescope from stray light.

“Optical instruments like cameras and telescopes have to get rid of unwanted glare, so you can see what you want to see,” Mather says. “Would you like to see an Earth orbiting another star? We need something very black. … And this black has to be tough to withstand a rocket launch. Old versions were fragile forests of fur, but these are more like pot scrubbers — built to take abuse.”

[Note] An earlier version of this story stated that the new material captures more than 99.96 percent of incoming light. That number has been updated to be more precise; the material absorbs at least 99.995 of incoming light.

Here’s an August 29, 2019 news release from MIT announcing the then upcoming show. Usually I’d expect to see a research paper associated with this work but this time it seems to an art exhibit only,

The MIT Center for Art, Science &Technology (CAST) and the New York Stock Exchange (NYSE) will present The Redemption of Vanity,created by artist Diemut Strebe in collaboration with MIT scientist Brian Wardle and his lab, on view at the New York Stock Exchange September 13, 2019 -November 25, 2019. For the work, a 16.78 carat natural yellow diamond valued at $2 million from L.J.West was coated using a new procedure of generating carbon nanotubes (CNTs), recently measured to be the blackest black ever created, which makes the diamond seem to disappear into an invisible void. The patented carbon nanotube technology (CNT) absorbs more than 99.96% of light and was developed by Professor Wardle and his necstlablab at MIT.

“Any object covered with this CNT material loses all its plasticity and appears entirely flat, abbreviated/reduced to a black silhouette. In outright contradiction to this we see that a diamond,while made of the very same element (carbon) performs the most intense reflection of light on earth.Because of the extremely high light absorbtive qualities of the CNTs, any object, in this case a large diamond coated with CNT’s, becomes a kind of black hole absent of shadows,“ explains Strebe.“The unification of extreme opposites in one object and the particular aesthetic features of the CNTs caught my imagination for this art project.”

“Strebe’s art-science collaboration caused us to look at the optical properties of our new CNT growth, and we discovered that these particular CNTs are blacker than all other reported materials by an order of magnitude across the visible spectrum”, says Wardle. The MIT team is offering the process for any artist to use. “We do not believe in exclusive ownership of any material or idea for any artwork and have opened our method to any artist,” say Strebe and Wardle.“

The project explores material and immaterial value attached to objects and concepts in reference to luxury, society and to art. We are presenting the literal devaluation of a diamond, which is highly symbolic and of high economic value.It presents a challenge to art market mechanisms on the one hand, while expressing at the same time questions of the value of art in a broader way. In this sense it manifests an inquiry into the significance of the value of objects of art and the art market,” says Strebe. “We are honored to present this work at The New York Stock Exchange, which I believe to be a most fitting location to consider the ideas embedded in The Redemption of Vanity.”

“The New York Stock Exchange, a center of financial and technological innovation for 227 years, is the perfect venue to display Diemut Strebe and Professor Brian Wardle’s collaboration. Their work brings together cutting-edge nanotube technology and a natural diamond, which is a symbol of both value and longevity,” said John Tuttle, NYSE Group Vice Chairman & Chief Commercial Officer.

“We welcome all scientists and artists to venture into the world of natural color diamonds. The Redemption of Vanity exemplifies the bond between art, science, and luxury. The 16-carat vivid yellow diamond in the exhibit spent millions of years in complete darkness, deep below the earth’s surface. It was only recently unearthed —a once-in-a-lifetime discovery of exquisite size and color. Now the diamond will relive its journey to darkness as it is covered in the blackest of materials. Once again, it will become a reminder that something rare and beautiful can exist even in darkness,”said Larry West.

The “disappearing” diamond in The Redemption of Vanity is a $2 Million Fancy Vivid Yellow SI1 (GIA), Radiant shape, from color diamond specialist, L.J. West Diamonds Inc. of New York.

The Redemption of Vanity, conceived by Diemut Strebe, has been realized with Brian L. Wardle, Professor of Aeronautics and Astronautics and Director of necstlab and Nano-Engineered Composite aerospace STructures (NECST) Consortium and his team Drs. Luiz Acauan and Estelle Cohen, in conjunction with Strebe’s residency at MIT supported by the Center for Art, Science & Technology (CAST).

ABOUT THE ARTISTS

Diemut Strebe is a conceptual artist based in Boston, MA and a MIT CAST Visiting Artist. She has collaborated with several MIT faculty, including Noam Chomsky and Robert Langer on Sugababe (2014), Litmus (2014) and Yeast Expression(2015); Seth Lloyd and Dirk Englund on Wigner’s Friends(2014); Alan Guth on Plötzlich! (2018); researchers in William Tisdale’s Lab on The Origin of the Works of Art(2018); Regina Barzilay and Elchanan Mossel on The Prayer (2019); and Ken Kamrin and John Brisson on The Gymnast (2019). Strebe is represented by the Ronald Feldman Gallery.

Brian L. Wardle is a Professor of Aeronautics and Astronautics at MIT and the director of the necstlab research group and MIT’s Nano-Engineered Composite aerospace STructures (NECST) Consortium. Wardle previously worked with CAST Visiting Artist Trevor Paglen on The Last Picturesproject (2012).

ABOUT THE MIT CENTER FOR ART, SCIENCE & TECHNOLOGY

A major cross-school initiative, the MIT Center for Art, Science & Technology (CAST) creates new opportunities for art, science and technology to thrive as interrelated, mutually informing modes of exploration, knowledge and discovery. CAST’s multidisciplinary platform presents performing and visual arts programs, supports research projects for artists working with science and engineering labs, and sponsors symposia, classes, workshops, design studios, lectures and publications. The Center is funded in part by a generous grant from the Andrew W. Mellon Foundation. Evan Ziporyn is the Faculty Director and Leila W. Kinney is the Executive Director.Since its inception in 2012, CAST has been the catalyst for more than 150 artist residencies and collaborative projects with MIT faculty and students, including numerous cross-disciplinary courses, workshops, concert series, multimedia projects, lectures and symposia. The visiting artists program is a cornerstone of CAST’s activities, which encourages cross-fertilization among disciplines and intensive interaction with MIT’s faculty and students. More info at https://arts.mit.edu/cast/ .

HISTORY OF VISITING ARTISTS AT MIT

Since the late 1960s, MIT has been a leader in integrating the arts and pioneering a model for collaboration among artists, scientists and engineers in a research setting. CAST’s Visiting Artists Program brings internationally acclaimed artists to engage with MIT’s creative community in ways that are mutually enlightening for the artists and for faculty, students and research staff at the Institute. Artists who have worked extensively at MIT include Mel Chin, Olafur Eliasson, Rick Lowe, Vik Muniz, Trevor Paglen, Tomás Saraceno, Maya Beiser, Agnieszka Kurant, and Anicka Yi.

ABOUT L.J. WEST DIAMONDS

L.J. West Diamonds is a three generation natural color diamond whole sale rfounded in the late 1970’s by Larry J. West and based in New York City. L.J. West has established itself as one of the world’s prominent houses for some of the most rare and important exotic natural fancy color diamonds to have ever been unearthed. This collection includes a vast color spectrum of rare pink, blue, yellow, green, orange and red diamonds. L.J. West is an expert in every phase of the jewelry process –from sourcing to the cutting, polishing and final design. Each exceptional jewel is carefully set to become a unique work of art.The Redemption of Vanity is on view at the New York Stock Exchange by appointment only.

Press viewing: September 13, 2019 at 3pmNew York Stock Exchange, 11 Wall Street, New York, NY 10005RSVP required. Please check-in at the blue tent at 2 Broad Street(at the corner of Wall and Broad Streets). All guests are required to show a government issued photo ID and go through airport-like security upon entering the NYSE.NYSE follows a business casual dress code -jeans & sneakers are not permitted.

No word yet if there will be other showings.

An artistic feud (of sorts)

Earlier this year, I updated a story on Vantablack. It was the blackest black, blocking 99.8% of light when I featured it in a March 14, 2016 posting. The UK company making the announcement, Surrey NanoSystems, then laid the groundwork for an artistic feud when it granted exclusive rights to their carbon nanotube-based coating, Vantablack, to Sir Anish Kapoor mentioned here in an April 16, 2016 posting.

This exclusivity outraged some artists notably, Stuart Semple. In his first act of defiance, he created the pinkest pink. Next, came a Kickstarter campaign to fund Semple’s blackest black, which would be available to all artists except Anish Kapoor. You can read all about the pinkest pink and blackest black as per Semple in my February 21, 2019 posting. You can also get a bit of an update in an Oct. 17, 2019 Stuart Semple proffile by Berenice Baker for Verdict,

… so I managed to hire a scientist, Jemima, to work in the studio with me. She got really close to a super black, and we made our own pigment to this recipe and it was awesome, but we couldn’t afford to put it into manufacture because it cost £25,000.”

Semple launched a Kickstarter campaign and was amazed to raise half a million pounds, making it the second most-supported art Kickstarter of all time.

…

The ‘race to the blackest’ is well underway, with MIT researchers recently announcing a carbon nanotube-based black whose light absorption they tested by coasting a diamond. But Semple is determined that his black should be affordable by all artists and work like a paint, not only perform in laboratory conditions. He’s currently working with Jemima and two chemists to upgrade the recipe for Black 3.2.

…

I don’t know how Semple arrived at his blackest black. I think it’s unlikely that he achieved the result by working with carbon nanotubes since my understanding is that CNTs aren’t that easy to produce.

Finally

Interesting, eh? In just a few years scientists have progressed from achieving a 99.8% black to 99.999%. It doesn’t seem like that big a difference to me but with Solomon Woods, at the beginning of this post, making the point that our eyes are very sensitive to light, an artistic feud, and a study uncovering deep emotions, getting the blackest black is a much more artistically fraught endeavour than I had imagined.