A March 8, 2023 news item on phys.org announces research from Swiss and Italian researchers into a new type of memristor,

Researchers at Empa, ETH Zurich and the Politecnico di Milano are developing a new type of computer component that is more powerful and easier to manufacture than its predecessors. Inspired by the human brain, it is designed to process large amounts of data fast and in an energy-efficient way.

In many respects, the human brain is still superior to modern computers. Although most people can’t do math as fast as a computer, we can effortlessly process complex sensory information and learn from experiences, while a computer cannot – at least not yet. And, the brain does all this by consuming less than half as much energy as a laptop.

One of the reasons for the brain’s energy efficiency is its structure. The individual brain cells – the neurons and their connections, the synapses – can both store and process information. In computers, however, the memory is separate from the processor, and data must be transported back and forth between these two components. The speed of this transfer is limited, which can slow down the whole computer when working with large amounts of data.

One possible solution to this bottleneck are novel computer architectures that are modeled on the human brain. To this end, scientists are developing so-called memristors: components that, like brain cells, combine data storage and processing. A team of researchers from Empa, ETH Zurich and the “Politecnico di Milano” has now developed a memristor that is more powerful and easier to manufacture than its predecessors. The researchers have recently published their results in the journal Science Advances.

…

A March 8, 2023 Swiss Federal Laboratories for Materials Science and Technology (EMPA) press release (also on EurekAlert), which originated the news item, provides details about what makes this memristor different,

Performance through mixed ionic and electronic conductivity

The novel memristors are based on halide perovskite nanocrystals, a semiconductor material known from solar cell manufacturing. “Halide perovskites conduct both ions and electrons,” explains Rohit John, former ETH Fellow and postdoctoral researcher at both ETH Zurich and Empa. “This dual conductivity enables more complex calculations that closely resemble processes in the brain.”

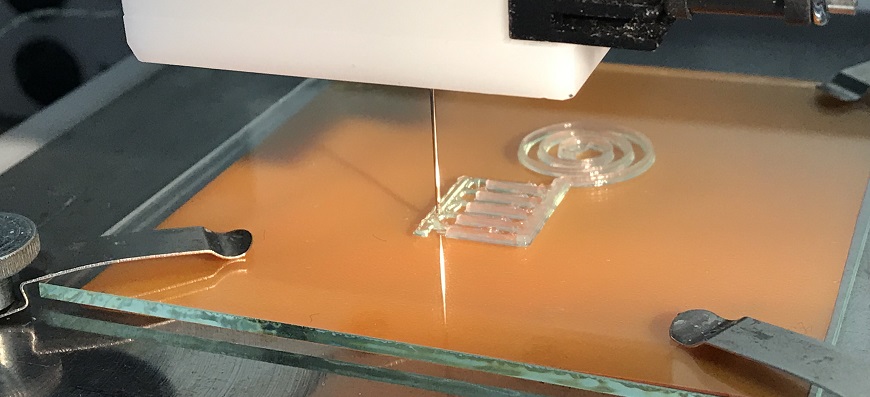

The researchers conducted the experimental part of the study entirely at Empa: They manufactured the thin-film memristors at the Thin Films and Photovoltaics laboratory and investigated their physical properties at the Transport at Nanoscale Interfaces laboratory. Based on the measurement results, they then simulated a complex computational task that corresponds to a learning process in the visual cortex in the brain. The task involved determining the orientation of light based on signals from the retina.

“As far as we know, this is only the second time this kind of computation has been performed on memristors,” says Maksym Kovalenko, professor at ETH Zurich and head of the Functional Inorganic Materials research group at Empa. “At the same time, our memristors are much easier to manufacture than before.” This is because, in contrast to many other semiconductors, perovskites crystallize at low temperatures. In addition, the new memristors do not require the complex preconditioning through application of specific voltages that comparable devices need for such computing tasks. This makes them faster and more energy-efficient.

Complementing rather than replacing

The technology, though, is not quite ready for deployment yet. The ease with which the new memristors can be manufactured also makes them difficult to integrate with existing computer chips: Perovskites cannot withstand temperatures of 400 to 500 degrees Celsius that are needed to process silicon – at least not yet. But according to Daniele Ielmini, professor at the “Politecnico di Milano”, that integration is key to the success for new brain-like computer technologies. “Our goal is not to replace classical computer architecture,” he explains. “Rather, we want to develop alternative architectures that can perform certain tasks faster and with greater energy efficiency. This includes, for example, the parallel processing of large amounts of data, which is generated everywhere today, from agriculture to space exploration.”

Promisingly, there are other materials with similar properties that could be used to make high-performance memristors. “We can now test our memristor design with different materials,” says Alessandro Milozzi, a doctoral student at the “Politecnico di Milano”. “It is quite possible that some of them are better suited for integration with silicon.”

Here’s a link to and a citation for the paper,

Ionic-electronic halide perovskite memdiodes enabling neuromorphic computing with a second-order complexity by Rohit Abraham John, Alessandro Milozzi, Sergey Tsarev, Rolf Brönnimann, Simon C. Boehme, Erfu Wu, Ivan Shorubalko, Maksym V. Kovalenko, and Daniele Ielmini. Science Advances 23 Dec 2022 Vol 8, Issue 51 DOI: 10.1126/sciadv.ade0072

This paper is open access.