Focus Graphite, a Canadian company with the tag line ‘Think Graphite today, Think Graphene tomorrow’, is making a bit of splash this month (April 2013) with its announcement of three deals (two joint ventures and the commissioning of their pilot plant) and it’s only April 17.

The most recent is the pilot plant announcement, from Focus Graphite’s Apr. 17, 2013 press release,

Focus Graphite Inc. (TSX-V:FMS)(OTCQX:FCSMF)(FRANKFURT:FKC) (“Focus” or the “Company”) is pleased to report the commissioning of its pilot plant and the start-up of circuit testing for the production of high-grade graphite concentrates from the Company’s wholly-owned Lac Knife, Québec graphite project.

The principal objectives of the pilot plant testwork are to confirm the results from Phase II bench scale Locked Cycle Tests (LCT)*; to assess the technical viability and operational performance of the processing plant design; to generate tailings for environmental testing, and; to produce a range of graphite raw materials for customer assessments and for further upgrading.

The Lac Knife project pilot plant was designed and built and is being operated by SGS Canada Inc. (“SGS”) in Lakefield, Ontario. The testing is expected to last 4-6 weeks.

….

The highlights of those tests conducted by SGS confirmed:- The average amount of graphite flake recovered from the core samples in the Phase II LCT increased to 92.2% compared with a recovery of 84.7% graphite flake in the Phase I LCT;

– The proportion of large flakes (+80 mesh) in the graphite concentrates ranged between 35% and 58%;

– The carbon content of graphite concentrates produced from the four (4) composites averaged 96.6 %C, including the fine flake fraction (-200 mesh), a 4.6% increase over Phase I LCT completed in mid-2012.

Final results for Phase II LCT including for the two composite drill core samples of massive graphite mineralisation are pending.

* A locked cycle test is a repetitive batch flotation test conducted to assess flow sheet design. It is the preferred method for arriving at a metallurgical projection from laboratory testing. The final cycles of the test are designed to simulate a continuous, stable flotation circuit.

There’s also the announcement of a joint venture between Grafoid (a company where, I believe, 40% is owned by Focus Graphite) with the University of Waterloo, from the Apr. 17, 2013 news item on Azonano,

Focus Graphite Inc. on behalf of Grafoid Inc. (“Grafoid”) is pleased to announce the signing of a two-year R&D agreement between Grafoid Inc. and the University of Waterloo to investigate and develop a graphene-based composite for electrochemical energy storage for the automotive and/or portable electronics sectors.

Gary Economo, President and CEO of Focus Graphite Inc. and Grafoid Inc., said the objective of the agreement is to research and develop patentable applications using Grafoid’s unique investment which derives graphene from raw, graphite ore to target specialty high value graphene derivatives ranging from sulfur graphene to nanoporous graphene foam.

…

“Today’s announcement marks Grafoid’s fifth publicly declared graphene development project with a major academic or corporate institution, and the third related directly to a next generation green technology or renewable energy development project,” Mr. Economo said.

It follows R&D partnering projects announced with Rutgers University’s AMIPP, CVD Equipment Corporation, with Hydro-Quebec’s research institute, IREQ, and with British Columbia-based CapTherm Systems, an advanced thermal management technologies developer and producer.

Focus Graphite’s Apr. 16, 2013 press release, which originated the news item on Azonano, provides some context for the intense worldwide interest in graphene and the business imperatives,

Alternative Energy & Graphene:

The quest for alternative energy sources is one of the most important and exciting challenges facing science and technology in the 21st century. Environmentally-friendly, efficient and sustainable energy generation and usage have become large efforts for advancing human societal needs. Graphene is a pure form of carbon with powerful characteristics which can bring about success in portable, stationary and transportation applications in high energy demanding areas in which electrochemical energy storage and conversion devices such as batteries, fuel cells and electrochemical supercapacitors are the necessary devices.

Electrochemical Supercapacitors:

Supercapacitors, a zero-emission energy storage system, have a number of high-impact characteristics, such as fast charging, long charge-discharge cycles and broad operating temperature ranges, currently used or heavily researched in hybrid or electrical vehicles, electronics, aircrafts, and smart grids for energy storage. The US Department of Energy has assigned the same importance to supercapacitors and batteries. There is much research looking at combining electrochemical supercapacitors with battery systems or fuel cells.

Fuel Cells:

A fuel cell is a zero-emission source of power, and the only byproduct of a fuel cell is water. Some fuel cells use natural gas or hydrocarbons as fuel, but even those produce far less emissions than conventional sources. As a result, fuel cells eliminate or at least vastly reduce the pollution and greenhouse gas emissions caused by burning fossil fuels, and since they are also quiet in operation, they also reduce noise pollution. Fuel cells are more efficient than combustion engines as they generate electricity electrochemically. Since they can produce electricity onsite, the waste heat produced can also be used for heating purposes. Small fuel cells are already replacing batteries in portable products.

Toyota is planning to launch fuel cell cars in 2015, and has licensed its fuel cell vehicle technology to Germany’s BMW AG. BMW will use the technology to build a prototype vehicle by 2015, with plans for a market release around 2020.

By 2020, market penetration could rise as high as 1.2 million fuel cell vehicles, which would represent 7.6% of the total U.S. automotive market. Other fuel cell end users are fork lift and mining industries which continuously add profits to this growing industry.

Proton or polymer exchange membranes (PEM) have become the dominant fuel cell technology in the automotive market.

The U.S. Department of Energy has set fuel cell performance standards for 2015. As of today, no technologies under development have been able to meet the DOE’s targets for performance and cost.

As I am from British Columbia and it was where* the first joint venture deal signed in April, here’s a bit more from Focus Graphite’s Apr. 9, 2013 press release,

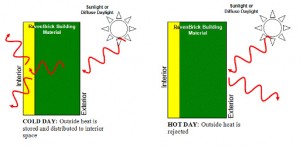

Focus Graphite Inc. (TSX-V:FMS)(OTCQX:FCSMF)(FRANKFURT:FKC) on behalf of Grafoid Inc., announced today Grafoid’s joint venture development agreement with Coquitlam, British Columbia-based CapTherm Systems Inc. to develop and commercialize next generation, multiphase thermal management systems for electric vehicle (EV) battery and light emitting diode (LED) technologies.

CapTherm Systems Inc – Progressive Thermal Management is a thermal management/cooling company specializing in personal computer, server, LED, and electric vehicle cooling systems. It develops and commercializes proprietary, next-generation high-power electronics cooling technologies.

Its multiphase cooling technologies represent the core of its products that harness the power of latent heat from vaporization.

Under the terms of the agreement, Grafoid Inc., a company invested in the production of high-energy graphene and the development of graphene industrial applications will supply both materials and its science for adapting graphene to CapTherm’s existing EV and LED cooling systems.

Focus Graphite is a Canadian company, you can find more information on their website and the same for Grafoid and SGS Canada, and CapTherm Systems.

I have previously mentioned Focus Graphite in a Nov. 27, 2012 posting about their deal with Hydro Québec’s research institute, IREQ. I have also mentioned graphite mining in Canada with regard to the Northern Graphite Corporation and its Bissett Creek mine (my July 25, 2011 posting and my Feb. 6, 2012 posting). Apparently, Canada has high quality, large graphic flakes.

* ‘where’ added to sentence on Feb. 23, 2015.