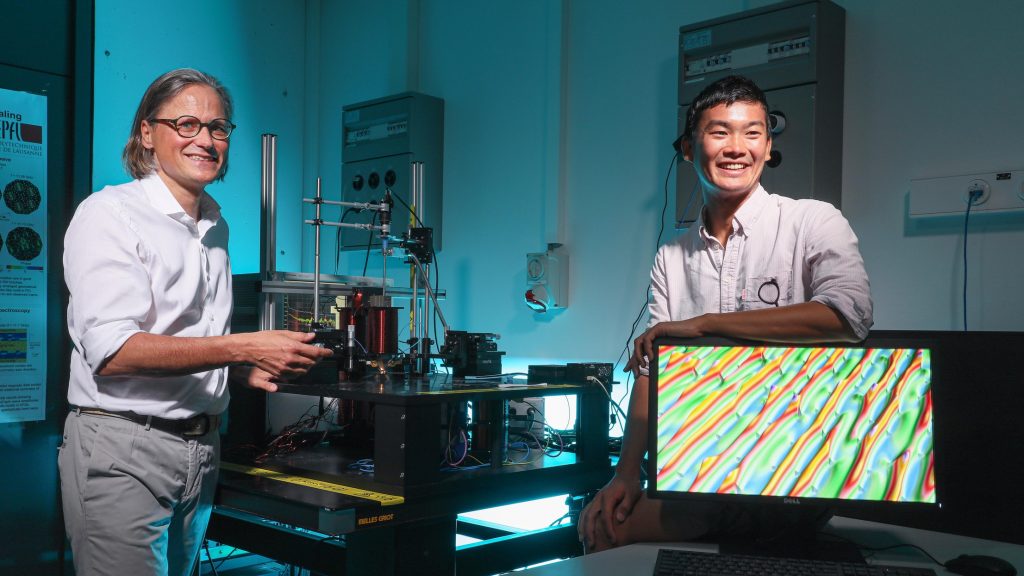

These days I need a little joy and these two researchers seem happy to share,

A July 15, 2020 news item on phys.org announces the development that so delights these researchers,

Researchers at EPFL [École polytechnique fédérale de Lausanne; Switzerland] have shown that electromagnetic waves coupled to precisely engineered structures known as artificial ferromagnetic quasicrystals allow for more efficient information transmission and processing at the nanoscale. Their research also represents the first practical demonstration of Conway worms, a theoretical concept for the description of quasicrystals.

…

A July 15, 2020 EPFL press release, which originated the news item, explains further,

High-frequency electromagnetic waves are used to transmit and process information in microelectronic devices such as smartphones. It’s already appreciated that these waves can be compressed using magnetic oscillations known as spin waves or magnons. This compression could pave the way for the design of nanoscale, multifunctional microwave devices with a considerably reduced footprint. But first, scientists need to gain a better understanding of spin waves – or precisely how magnons behave and propagate in different structures.

Learning more about aperiodic structures

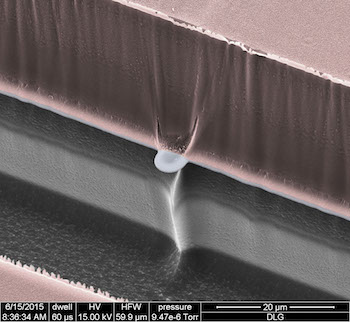

In a study conducted by the doctoral assistant Sho Watanabe, postdoctoral researcher Dr. Vinayak Bhat, and further team members, the scientists from EPFL’s Laboratory of Nanoscale Magnetic Materials and Magnonics (LMGN) examined how electromagnetic waves propagate, and how they could be manipulated, in precisely engineered nanostructures known as artificial ferromagnetic quasicrystals. The quasicrystals have a unique property: their structure is aperiodic, meaning that their constituent atoms or tailor-made elements do not follow a regular, repeating pattern but are still arranged deterministically. Although this characteristic makes materials especially useful for the design of everyday and high-tech devices, it remains poorly understood.

Faster, easier transmission of information

The LMGN team found that, under controlled conditions, a single electromagnetic wave coupled to an artificial quasicrystal splits into several spin waves, which then propagate within the structure. Each of these spin waves represents a different phase of the original electromagnetic wave, carrying different information. “It’s a very interesting discovery, because existing information-transmission methods follow the same principle,” says Dirk Grundler, an associate professor at EPFL’s School of Engineering (STI). “Except you need an extra device, a multiplexer, to split the input signal because – unlike in our study – it doesn’t divide on its own.”

Grundler also explains that, in conventional systems, the information contained in each wave can only be read at different frequencies – another inconvenience that the EPFL team overcame in their study. “In our two-dimensional quasicrystals, all the waves can be read at the same frequency,” he adds. The findings have been published in the journal Advanced Functional Materials.

Waves that spread like worms

The researchers also observed that, rather than propagating randomly, the waves often moved like so-called Conway worms, named after a well-known mathematician John Horton Conway who also developed a model to describe the behavior and feeding patterns of prehistoric worms. Conway discovered that, within two-dimensional quasicrystals, constituent elements arrange like meandering worms following a Fibonacci sequence. Thereby they form selected one-dimensional quasicrystals. “Our study represents the first practical demonstration of this theoretical concept, proving that the sequences induce interesting functional properties of waves in a quasicrystal,” says Grundler.

Take a look at that last paragraph. A mathematician develops a model for how prehistoric worms may have moved and applies it, theoretically, to 2D quasicrystals which these researchers believe they’ve observed in the laboratory and they believe this may have an impact on our future electronic devices. Sometimes I sit at home in wonder.

Here’s a link to and a citation for the paper,

Direct Observation of Worm‐Like Nanochannels and Emergent Magnon Motifs in Artificial Ferromagnetic Quasicrystals by Sho Watanabe, Vinayak S. Bhat, Korbinian Baumgaert, Dirk Grundler. Advanced Functional Materials DOI: https://doi.org/10.1002/adfm.202001388 First published: 15 July 2020

This is an open access paper.

The mention of quasicrystals reminded me of Daniel Schechtman who received the Nobel Prize for Chemistry in 2011 and who was mentioned in a December 24, 2013 posting here,

“I suggested earlier that this achievement has a fabulous quality and the Daniel Schechtman backstory is the reason. The winner of the 2011 Nobel Prize for Chemistry, Schechtman was reviled for years [emphasis mine] within his scientific community as Ian Sample notes in his Oct. 5, 2011 article on the announcement of Schechtman’s Nobel win written for the Guardian newspaper (Note: A link has been removed),

A scientist whose work was so controversial he was ridiculed and asked to leave his research group has won the Nobel Prize in Chemistry.

Daniel Shechtman, 70, a researcher at Technion-Israel Institute of Technology in Haifa, received the award for discovering seemingly impossible crystal structures in frozen gobbets of metal that resembled the beautiful patterns seen in Islamic mosaics.

Images of the metals showed their atoms were arranged in a way that broke well-establised rules of how crystals formed, a finding that fundamentally altered how chemists view solid matter.

…

You may want to click on the Guardian link to the full story about Schechtman and his quasicrystals. As for my December 24, 2013 posting, that features news of the creation of the first single-element quasicrystal in a laboratory along with an excerpt of the Schechtman story (scroll down about 50% of the way).