Rather that cooling or heating an entire room, why not cool or heat the person? Engineers at Stanford University (California, US) have developed a material that helps with half of that premise: cooling. From a Sept. 1, 2016 news item on ScienceDaily,

Stanford engineers have developed a low-cost, plastic-based textile that, if woven into clothing, could cool your body far more efficiently than is possible with the natural or synthetic fabrics in clothes we wear today.

Describing their work in Science, the researchers suggest that this new family of fabrics could become the basis for garments that keep people cool in hot climates without air conditioning.

“If you can cool the person rather than the building where they work or live, that will save energy,” said Yi Cui, an associate professor of materials science and engineering and of photon science at Stanford.

A Sept. 1, 2016 Stanford University news release (also on EurekAlert) by Tom Abate, which originated the news item, further explains the information in the video,

This new material works by allowing the body to discharge heat in two ways that would make the wearer feel nearly 4 degrees Fahrenheit cooler than if they wore cotton clothing.

The material cools by letting perspiration evaporate through the material, something ordinary fabrics already do. But the Stanford material provides a second, revolutionary cooling mechanism: allowing heat that the body emits as infrared radiation to pass through the plastic textile.

All objects, including our bodies, throw off heat in the form of infrared radiation, an invisible and benign wavelength of light. Blankets warm us by trapping infrared heat emissions close to the body. This thermal radiation escaping from our bodies is what makes us visible in the dark through night-vision goggles.

“Forty to 60 percent of our body heat is dissipated as infrared radiation when we are sitting in an office,” said Shanhui Fan, a professor of electrical engineering who specializes in photonics, which is the study of visible and invisible light. “But until now there has been little or no research on designing the thermal radiation characteristics of textiles.”

Super-powered kitchen wrap

To develop their cooling textile, the Stanford researchers blended nanotechnology, photonics and chemistry to give polyethylene – the clear, clingy plastic we use as kitchen wrap – a number of characteristics desirable in clothing material: It allows thermal radiation, air and water vapor to pass right through, and it is opaque to visible light.

The easiest attribute was allowing infrared radiation to pass through the material, because this is a characteristic of ordinary polyethylene food wrap. Of course, kitchen plastic is impervious to water and is see-through as well, rendering it useless as clothing.

The Stanford researchers tackled these deficiencies one at a time.

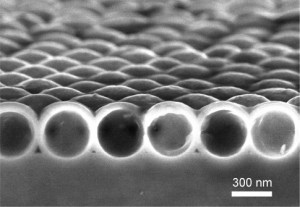

First, they found a variant of polyethylene commonly used in battery making that has a specific nanostructure that is opaque to visible light yet is transparent to infrared radiation, which could let body heat escape. This provided a base material that was opaque to visible light for the sake of modesty but thermally transparent for purposes of energy efficiency.

They then modified the industrial polyethylene by treating it with benign chemicals to enable water vapor molecules to evaporate through nanopores in the plastic, said postdoctoral scholar and team member Po-Chun Hsu, allowing the plastic to breathe like a natural fiber.

Making clothes

That success gave the researchers a single-sheet material that met their three basic criteria for a cooling fabric. To make this thin material more fabric-like, they created a three-ply version: two sheets of treated polyethylene separated by a cotton mesh for strength and thickness.

To test the cooling potential of their three-ply construct versus a cotton fabric of comparable thickness, they placed a small swatch of each material on a surface that was as warm as bare skin and measured how much heat each material trapped.

“Wearing anything traps some heat and makes the skin warmer,” Fan said. “If dissipating thermal radiation were our only concern, then it would be best to wear nothing.”

The comparison showed that the cotton fabric made the skin surface 3.6 F warmer than their cooling textile. The researchers said this difference means that a person dressed in their new material might feel less inclined to turn on a fan or air conditioner.

The researchers are continuing their work on several fronts, including adding more colors, textures and cloth-like characteristics to their material. Adapting a material already mass produced for the battery industry could make it easier to create products.

“If you want to make a textile, you have to be able to make huge volumes inexpensively,” Cui said.

Fan believes that this research opens up new avenues of inquiry to cool or heat things, passively, without the use of outside energy, by tuning materials to dissipate or trap infrared radiation.

“In hindsight, some of what we’ve done looks very simple, but it’s because few have really been looking at engineering the radiation characteristics of textiles,” he said.

Dexter Johnson (Nanoclast blog on the IEEE [Institute of Electrical and Electronics Engineers] website) has written a Sept. 2, 2016 posting where he provides more technical detail about this work,

The nanoPE [nanoporous polyethylene] material is able to achieve this release of the IR heat because of the size of the interconnected pores. The pores can range in size from 50 to 1000 nanometers. They’re therefore comparable in size to wavelengths of visible light, which allows the material to scatter that light. However, because the pores are much smaller than the wavelength of infrared light, the nanoPE is transparent to the IR.

It is this combination of blocking visible light and allowing IR to pass through that distinguishes the nanoPE material from regular polyethylene, which allows similar amounts of IR to pass through, but can only block 20 percent of the visible light compared to nanoPE’s 99 percent opacity.

The Stanford researchers were also able to improve on the water wicking capability of the nanoPE material by using a microneedle punching technique and coating the material with a water-repelling agent. The result is that perspiration can evaporate through the material unlike with regular polyethylene.

For those who wish to further pursue their interest, Dexter has a lively writing style and he provides more detail and insight in his posting.

Here’s a link to and a citation for the paper,

Radiative human body cooling by nanoporous polyethylene textile by Po-Chun Hsu, Alex Y. Song, Peter B. Catrysse, Chong Liu, Yucan Peng, Jin Xie, Shanhui Fan, Yi Cui. Science 02 Sep 2016: Vol. 353, Issue 6303, pp. 1019-1023 DOI: 10.1126/science.aaf5471

This paper is open access.

![[downloaded from Nature Communications: http://www.nature.com/ncomms/journal/v4/n1/full/ncomms2327.html]](http://www.frogheart.ca/wp-content/uploads/2013/01/EggYolkLi-ionBattery.jpg)