An August 6, 2019 article by Adele Peters for Fast Company describes a ‘wooden’approach to water desalinization (also known as desalination),

…

“We are trying to develop a new type of membrane material that is nature-based,” says Z. Jason Ren, an engineering professor at Princeton University and one of the coauthors of a new paper in Science Advances about that material, which is made from wood. It’s designed for use in a process called membrane distillation, which heats up saltwater and uses pressure to force the water vapor through a membrane, leaving the salt behind and creating pure water. The membranes are usually made from a type of plastic. Using “nanowood” membranes instead can both improve the energy efficiency of the process and avoid the environmental problems of plastic.

…

An August 2, 2019 University of Maryland (UMD) news release provides more detail about the research,

A membrane made of a sliver of wood could be the answer to renewably sourced water cleaning. Most membranes that are currently used to distill fresh water from salty are made of polymers based on fossil fuels.

Inspired by the intricate system of water circulating in a tree, a research team from the University of Maryland, Princeton University, and the University of Colorado Boulder have figured out how to use a thin slice of wood as a membrane through which water vapor can evaporate, leaving behind salt or other contaminants.

“This work demonstrates another exciting energy/water application of nanostructured wood, as a high-performance membrane material,” said Liangbing Hu, a professor of materials science and engineering at UMD’s A. James Clark School of Engineering, who co-led the study.

The team chemically treated the wood to become hydrophobic, so that it more efficiently allows water vapor through, driven by a heat source like solar energy.

“This study discovered a new way of using wood materials’ unique properties as both an excellent insulator and water vapor transporter,” said Z. Jason Ren, a professor in environmental engineering who recently moved from CU Boulder to Princeton, and the other co-leader of the team that performed the study.

The researchers treat the wood so that it loses its lignin, the part of the wood that makes it brown and rigid, and its hemicellulose, which weaves in and out between cellulose to hold it in place. The resulting “nanowood” is treated with silane, a compound used to make silicon for computer chips. The semiconducting nature of the compound maintains the wood’s natural nanostructures of cellulose, and clings less to water vapor molecules as they pass through. Silane is also used in solar cell manufacturing.

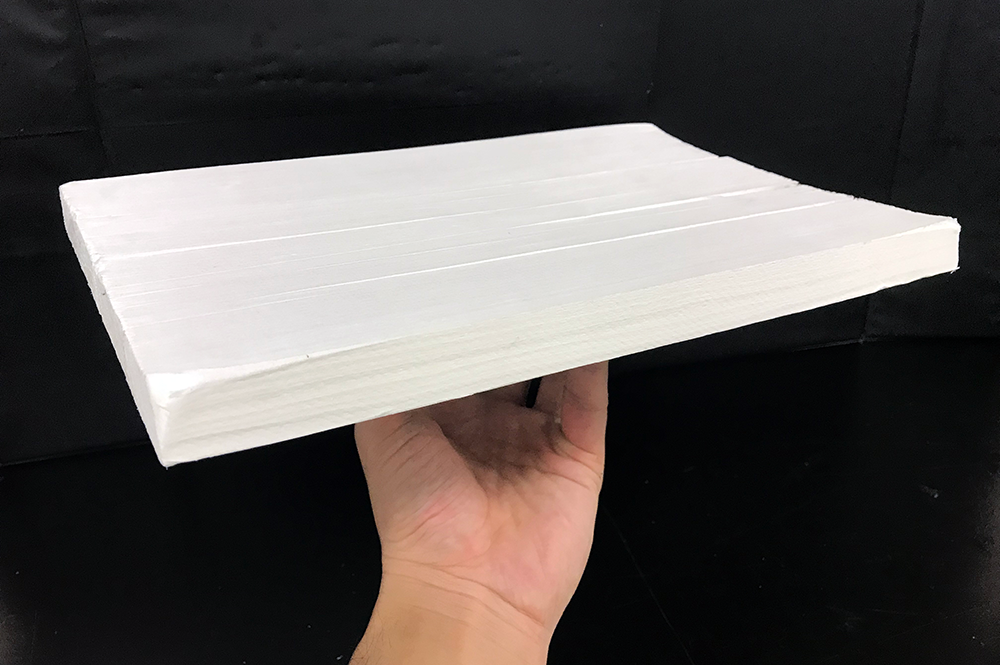

The membrane looks like a thin piece of wood, seemingly bleached white, that is suspended above a source of water vapor. As the water heats and passes into the gas phase, the molecules are small enough to fit through the tiny channels lining the walls of the leftover cell structure. Water collected on the other side is now free of large contaminants like salt.

To test it, the researchers distilled water through it and found that it performed 1.2 times better than a conventional membrane.“The wood membrane has very high porosity, which promotes water vapor transport and prevents heat loss,” said first author Dianxun Hou, who was a student at CU Boulder.

Inventwood, a UMD spinoff company of Hu’s research group, is working on commercializing wood based nanotechnologies.

Here’s a link to and a citation for the paper,

Hydrophobic nanostructured wood membrane for thermally efficient distillation by Dianxun Hou, Tian Li, Xi Chen, Shuaiming He, Jiaqi Dai, Sohrab A. Mofid, Deyin Hou, Arpita Iddya, David Jassby, Ronggui Yang, Liangbing Hu, and Zhiyong Jason Ren. Science Advances 02 Aug 2019: Vol. 5, no. 8, eaaw3203 DOI: 10.1126/sciadv.aaw3203

This paper appears to be open access.

In my brief survey of the paper, I noticed that the researchers were working with cellulose nanofibrils (CNF), a term which should be familiar for anyone following the nanocellulose story, such as it.