The microscopes used for nanoscale research were invented roughly 35 years ago and as fabulous as they’ve been, there is a problem (from a February 12, 2018 news item on Nanowerk),

A University of Texas at Dallas graduate student, his advisor and industry collaborators believe they have addressed a long-standing problem troubling scientists and engineers for more than 35 years: How to prevent the tip of a scanning tunneling microscope from crashing into the surface of a material during imaging or lithography.

The researchers have prepared this video describing their work,

For those who like text, there’s more in this February 12, 2018 University of Texas at Dallas news release,

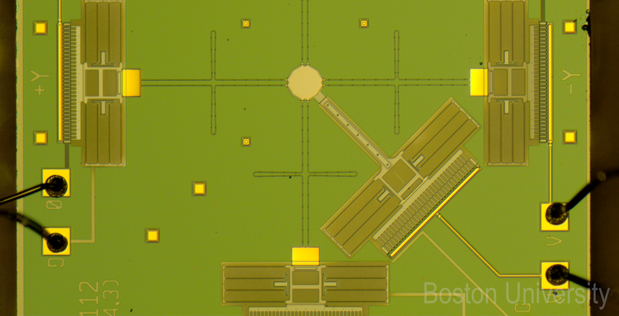

Scanning tunneling microscopes (STMs) operate in an ultra-high vacuum, bringing a fine-tipped probe with a single atom at its apex very close to the surface of a sample. When voltage is applied to the surface, electrons can jump or tunnel across the gap between the tip and sample.

“Think of it as a needle that is very sharp, atomically sharp,” said Farid Tajaddodianfar, a mechanical engineering graduate student in the Erik Jonsson School of Engineering and Computer Science. “The microscope is like a robotic arm, able to reach atoms on the sample surface and manipulate them.”

The problem is, sometimes the tungsten tip crashes into the sample. If it physically touches the sample surface, it may inadvertently rearrange the atoms or create a “crater,” which could damage the sample. Such a “tip crash” often forces operators to replace the tip many times, forfeiting valuable time.

Dr. John Randall is an adjunct professor at UT Dallas and president of Zyvex Labs, a Richardson, Texas-based nanotechnology company specializing in developing tools and products that fabricate structures atom by atom. Zyvex reached out to Dr. Reza Moheimani, a professor of mechanical engineering, to help address STMs’ tip crash problem. Moheimani’s endowed chair was a gift from Zyvex founder James Von Ehr MS’81, who was honored as a distinguished UTD alumnus in 2004.

“What they’re trying to do is help bring atomically precise manufacturing into reality,” said Randall, who co-authored the article with Tajaddodianfar, Moheimani and Zyvex Labs’ James Owen. “This is considered the future of nanotechnology, and it is extremely important work.”

Randall said such precise manufacturing will lead to a host of innovations.

“By building structures atom by atom, you’re able to create new, extraordinary materials,” said Randall, who is co-chair of the Jonsson School’s Industry Engagement Committee. “We can remove impurities and make materials stronger and more heat resistant. We can build quantum computers. It could radically lower costs and expand capabilities in medicine and other areas. For example, if we can better understand DNA at an atomic and molecular level, that will help us fine-tune and tailor health care according to patients’ needs. The possibilities are endless.”

In addition, Moheimani, a control engineer and expert in nanotechnology, said scientists are attempting to build transistors and quantum computers from a single atom using this technology.

“There’s an international race to build machines, devices and 3-D equipment from the atom up,” said Moheimani, the James Von Ehr Distinguished Chair in Science and Technology.

‘It’s a Big, Big Problem’

Randall said Zyvex Labs has spent a lot of time and money trying to understand what happens to the tips when they crash.

“It’s a big, big problem,” Randall said. “If you can’t protect the tip, you’re not going to build anything. You’re wasting your time.”

Tajaddodianfar and Moheimani said the issue is the controller.

“There’s a feedback controller in the STM that measures the current and moves the needle up and down,” Moheimani said. “You’re moving from one atom to another, across an uneven surface. It is not flat. Because of that, the distance between the sample and tip changes, as does the current between them. While the controller tries to move the tip up and down to maintain the current, it does not always respond well, nor does it regulate the tip correctly. The resulting movement of the tip is often unstable.”

It’s the feedback controller that fails to protect the tip from crashing into the surface, Tajaddodianfar said.

“When the electronic properties are variable across the sample surface, the tip is more prone to crash under conventional control systems,” he said. “It’s meant to be really, really sharp. But when the tip crashes into the sample, it breaks, curls backward and flattens.

“Once the tip crashes into the surface, forget it. Everything changes.”

The Solution

According to Randall, Tajaddodianfar took logical steps for creating the solution.

“The brilliance of Tajaddodianfar is that he looked at the problem and understood the physics of the tunneling between the tip and the surface, that there is a small electronic barrier that controls the rate of tunneling,” Randall said. “He figured out a way of measuring that local barrier height and adjusting the gain on the control system that demonstrably keeps the tip out of trouble. Without it, the tip just bumps along, crashing into the surface. Now, it adjusts to the control parameters on the fly.”

Moheimani said the group hopes to change their trajectory when it comes to building new devices.

“That’s the next thing for us. We set out to find the source of this problem, and we did that. And, we’ve come up with a solution. It’s like everything else in science: Time will tell how impactful our work will be,” Moheimani said. “But I think we have solved the big problem.”

Randall said Tajaddodianfar’s algorithm has been integrated with its system’s software but is not yet available to customers. The research was made possible by funding from the Army Research Office and the Defense Advanced Research Projects Agency.

Here’s a link to and a citation for the paper,

On the effect of local barrier height in scanning tunneling microscopy: Measurement methods and control implications by Farid Tajaddodianfar, S. O. Reza Moheimani, James Owen, and John N. Randall. Review of Scientific Instruments 89, 013701 (2018); https://doi.org/10.1063/1.5003851 Published Online: January 2018

This paper is behind a paywall.