Integran, a company based in Mississauga (sometimes identified as Toronto), Ontario, has received an award for its nanostructured alloy, a replacement for poisonous copper-beryllium, according to a Feb. 13, 2014 news item on Azonano,

Toronto-based Integran Technologies Inc. (Integran) today announced that it has received the 2013 SERDP (Strategic Environmental Research and Defense Program) Project-of-the-Year Award for Weapons Systems and Platforms for the development of a nanostructured alloy for copper-beryllium replacement.

For decades, essential parts in fixed and rotary wing military platforms have been made with copper-beryllium alloys. Beryllium is particularly useful for this purpose because it is both lightweight and strong, a rare combination not found in most other metals. The problem is beryllium is a toxic material that can be harmful to workers who handle it during assembly and repair. Working with beryllium, which requires donning protective gear and taking extensive precautions, is costly and time-consuming.

The Feb. 12, 2014 Integran news release found on MarketWire but oddly not on the company’s website at this time (Feb. 13, 2014) and which originated the news item, describes the process in general terms,

With support from US DoD’s SERDP program and Industry Canada’s Strategic Aerospace and Defense Initiative (SADI) program, Integran developed and validated an electroforming process that produces a nanostructured alloy that matches the desirable properties of copper-beryllium, particularly for use as high load bushings. This pulsed electroplating process goes beyond merely coating a metal object. Rather, near-net-shape components are created that require little to no machining to achieve final dimensions, resulting in very little material waste. The work also showed this innovative process can be used successfully for large metal sheets and high conductivity wires, both of which are used in multiple military applications.

Integran’s Aerospace and Defense R&D Unit Manager Brandon Bouwhuis states, “The validation testing performed in this project demonstrates that these nanostructured alloys can meet or exceed the performance of copper beryllium in many applications, and could result in substantial cost savings for the US DoD and Canadian Military through the decreased use of toxic substances.”

There is no mention in this news release as to whether Integran’s replacement alloy might itself be poisonous or toxic in some form.

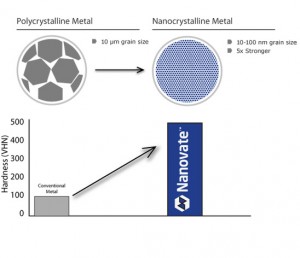

I checked the Integran website and found that it lists one product, Nanovate. I was not able to find any information about environmental testing but there is this on the company’s Why Nanovate™? webpage (Note: Links have been removed),

Integran is a world leader in development and manufacturing of revolutionary electrodeposited (plated) nanocrystalline “Nanovate™” metals. Our nanotechnology enabled metals take advantage of the fine crystalline grain structure to achieve superior performance at reduced weight vs conventional material solutions. Our technology platform consists primarily of Nickel, Iron, Cobalt and Copper alloys that we use to create high performance parts that are:

- Lighter, stronger, harder and cheaper than Aluminum

- Corrosion and wear resistant

- Shielded against low frequency magnetic interference

- Efficiently absorb energy and noise

In addition to manufacturing products, we also provide services such as:

- Plating on plastics, including polymers like polyamides (Nylon), PEEK and ABS

I have previously posted about Integran and its alloy many times including this April 16, 2012 posting referencing a Canadian government investment in the company’s technology.

As I was browsing the Integran website I found this on the company’s homepage,

The quintessential Canadian enterpreneur’s dream, creating an ‘unbreakable’ hockey stick that never gets ‘tired’. According to a Nov. 7, 2013 posting on the Integran News Blog, the hockey stick was a Kickstarter project,Congratulations to our partners, Colt Hockey, for meeting and exceeding their goal on Kickstarter to develop a higher performance and more durable composite hockey stick with PowerMetal Technologies. The project exceeded expectations with over $100,000 raised from almost 500 supporters.

…

This news item seemed particularly à propos during the 2014 Olympics. Good luck to the Canadian women’s and men’s teams!

![[downloaded from http://www.integran.com/default.aspx]](http://www.frogheart.ca/wp-content/uploads/2014/02/COLT_INTEGRAN-300x167.jpg)