Dove (a Unilever brand) claims that nanotechnology is involved but i can’t find anything other than the declaration. From a February 7, 2023 article by Julia Wray on cosmeticsbusiness.com,

A newly reformulated body wash from Dove is the first product of its kind in the US using nanotechnology to boost skin moisture.

The proprietary technology for Dove Body Wash featuring 24-hour Renewing MicroMoisture [emphasis mine] claims to nourish skin via millions of tiny droplets, which deposit onto the skin, fitting into cracks and crevices of dry skin for a smooth finish.

Stearic and palmitic fatty acids are said to penetrate deeply within the stratum corneum to visibly reduce dryness by 50% after each shower.

The new formula is accompanied by the Unilever brand’s first pack update in 17 years.

…

There’s the microscale (millionth) and the nanoscale (billionth)—not the same thing.

A February 22, 2023 Dove Canada news release provides a Canadian flavour to the news,

Today [February 22, 2023], Dove announces the latest advance in superior moisturization with the launch of NEW Dove Body Wash featuring 24-hour Renewing MicroMoisture. The new formula is powered by proprietary nano technology to actively generate the skin’s moisture, and has a new look to match, with a modern, user-friendly bottle design that reflects the first upgrade to Dove’s iconic bottle pack in 17 years.

Dove’s new formula continuously nourishes skin and improves its moisture barrier for a full 24 hours as well as uses proprietary technology with millions of moisturizing microdroplets to help boost and retain moisture. These tiny droplets deposit onto the skin, fitting into the gaps and crevices of dry skin for a silky-smooth finish, while stearic and palmitic fatty acids with Dove’s moisturizing blend penetrate deeply within the stratum corneum to visibly reduce dryness by 50% after every shower.

To accompany the new formula, Dove worked with leading cutting-edge designers and technicians to create the first upgrade to the iconic pack in 17 years – a beautiful bottle to match the skin it cares for. Long-time Dove users will recognize the coloured cap, representing their tried-and-true favourites, while the discreetly curved oval-shaped lid is a nod to where it all began for Dove – the Dove Beauty Bar. The Body Wash’s shower-friendly design not only means it is easy to use, but you can hold it, flip the cap, and dispense the body wash with just one hand. The bottle has even been crafted to allow it to be inverted on your bathroom shelves when it gets low and the cap can be completely removed, so it’s moisturizing to the last drop.

“Just like our bodies adapt and change as we move through life, so do our skincare preferences. Dove is continuing to understand these new changes through innovation and research.” says Rishabh Gandhi, Personal Care Director, Unilever Canada. “We are so thrilled to be launching our new Body Wash that accommodates all skincare needs by delivering the best in hydration while improving moisture barriers.”

…

To kick-off the Change is Beautiful pop-up [held Feb. 25 -26, 2023], Dove has partnered with iconic Canadian actress, Annie Murphy, [emphasis mine] to launch the new Dove body wash collection. Annie is best known for her starring role as Alexis Rose in the CBC sitcom Schitt’s Creek. “We’re born with skin (hopefully), the skin grows and changes (hopefully), and the growing and changing means we’re human (hopefully). Change is something I’m working on leaning into, instead of fighting against.” says Annie Murphy. “Dove puts a lot of consideration into everything they do, so I’m happy to be a part of their campaign that cares for our changing skin.”

…

I wasn’t able to find any specific references to nanotechnology and research on either the Dove or Unilever websites but I did find this July 12, 2022 Unilever news release “Research unlocks the secret to helping dry skin heal itself,” which offers some insight into the company’s research,

Cutting-edge research by Unilever scientists could unlock a new generation of personal care products to support our skin’s barrier.

…

For anyone who’s interested in nanotechnology and skincare, I found this historical perspective (link to article and citation follow the excerpt), Note: Links in excerpt have been removed,

Cosmetics include a wide range of products, mainly designed for external use and intended to cleanse, perfume, change the appearance of, correct odors emanating from, or more generally keep in good condition the areas of the body to which they are applied [1]. As a consequence of globalization, the role of these products is rapidly evolving and their use has been increasingly considered to be an essential part of personal wellness [2,3]. The improved life expectancy that has developed alongside the evolution of beauty standards has greatly changed consumer perceptions of routine daily care, which is no longer restricted to basic products (e.g., toothpaste, soap). Not surprisingly, the global beauty and personal care market value is predicted to exceed $716 billion by 2025, with much of that value related to the development of innovative and/or redesigned products and technologies [4].

The rapid rise of the cosmetics industry has been characterized by a growing demand for innovative and personalized products designed on the basis of increasingly detailed scientific knowledge [5]. In addition, the recent COVID-19 pandemic and associated global events have suggested that market trends for cosmetics are strongly affected by customer perceptions and are thus ever-changing; indeed, after years in which the demand has been increasingly oriented towards the use of “clean” and natural products, the pandemic has highlighted the need for safer and transparent items [6,7].

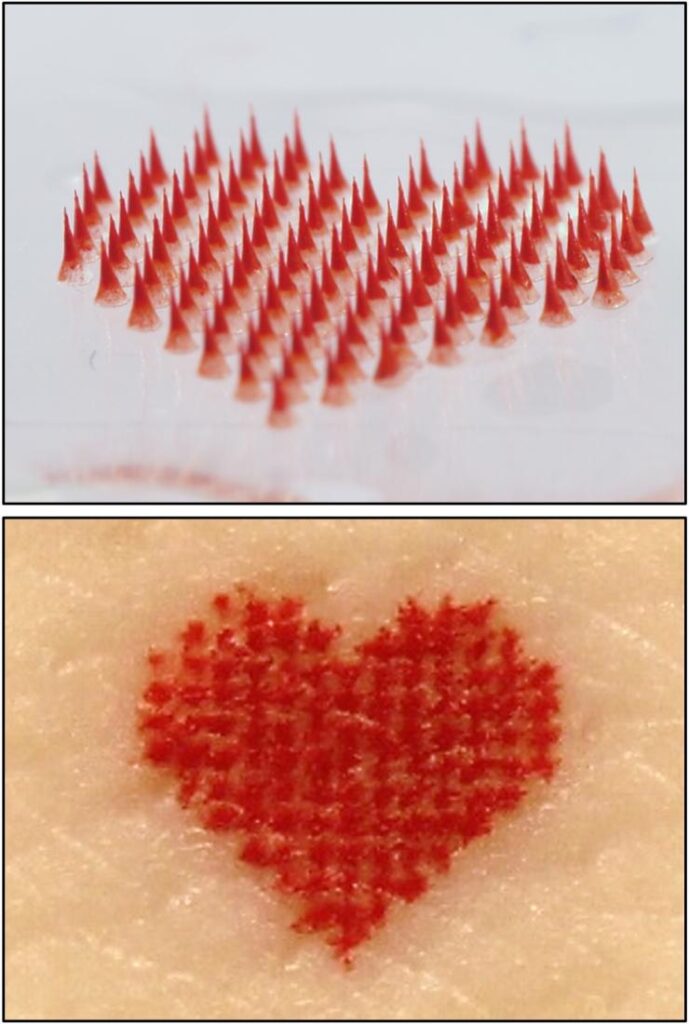

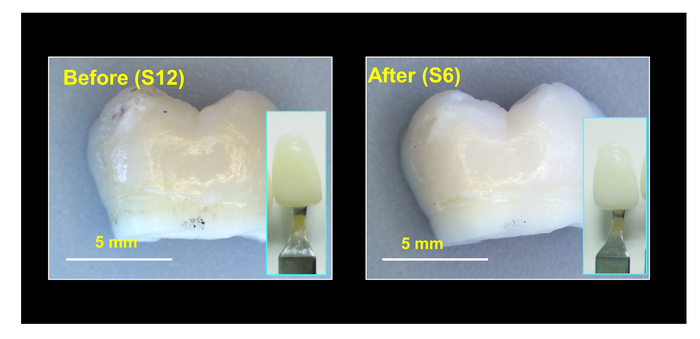

Back in 1986 [Note: Links have been removed], Lancôme and Dior simultaneously launched the first nanotechnology-based cosmetic products under the name of Niosomes® and Capture®, respectively [7,8]. The introduction of nanotechnology was pronounced to be a major scientific innovation and represented a major breakthrough towards the development of high-quality products; its use is now well-established in the cosmetics industry. Indeed, less demanding regulatory restrictions as compared to the development of new drugs, along with the localised action of these products, initially made the field extremely promising [9,10]. Nowadays, it is widely accepted that the use of nanoparticles (NPs) significantly improves the performance of cosmetics in diverse ways, performing both as an active ingredient and/or a carrier. For this reason, these technologies may be easily recognized as industry standards [11]. However, doubts about possible long-term [12] toxicity, together with concerns about the real advantages of nanomaterials in product performance, have often led to general mistrust [13,14]. Indeed, in late 2009 the European Union recast the individual directives associated with the use of cosmetics into a single platform collecting all of the relevant products. It was then proposed that the presence of nanomaterials in these products should necessitate additional restrictions before they are authorised for use as ingredients [15]. As a consequence, the cosmetics industry became wary of publicly promoting nanotechnology, often avoiding referring to ingredients as being composed of nanomaterials. Given this background, the present review aims to provide an update of the state of the art of the nanocosmetics field, exploring the beneficial effects of nanomaterials and offering a critical overview of toxicological issues. Among the various cosmetic product categories, our insights are mainly focused on skincare, which more clearly highlights the reappraisal of exploiting nanotechnology in cosmetics.

…

The researchers are from the University of Milano (Italy), so any reference to regulations and rules are almost certainly those that pertain to the European Union (EU).

Here’s a link to and a citation for the paper,

The emerging role of nanotechnology in skincare by Lucia Salvioni, Lucia Morelli, Evelyn Ochoa, Massimo Labra, Luisa Fiandra, Luca Palugan, Davide Prosperi, Miriam Colombo. Advances in Colloid and Interface Science Volume 293, July 2021, 102437 DOI: https://doi.org/10.1016/j.cis.2021.102437

This paper is open access.