Friday, Oct. 24, 2014 the Vancouver Sun (Canada) featured a local nanotechnology company, Nanozen in an article by ‘digital life’ writer, Gillian Shaw. Unfortunately, the article is misleading. Before noting the issues, it should be said that most reporters don’t have much time to prepare stories and are often asked to write on topics that are new or relatively unknown to them. It is a stressful position to be in especially when one is reliant on the interviewee’s expertise and agenda. As for the interviewee, sometimes scientists get excited and enthused and don’t speak with their usual caution.

The article starts off in an unexceptionable manner,

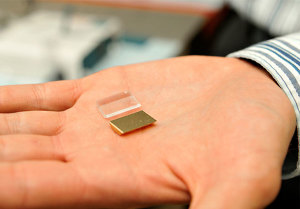

Vancouver startup Nanozen is a creating real-time, wearable particle sensor for use in mines, mills and other industrial locations where dust and other particles can lead to dangerous explosions and debilitating respiratory diseases.

The company founder and, presumably, lead researcher Winnie Chu is described as a former professor of environmental health at the University of British Columbia who has devoted herself to developing a new means of monitoring particles, in particular nanoparticles. Chu is quoted as saying this,

“The current technology is not sufficient to protect workers or the community when concentrations exceed the acceptable level,” she said.

It seems ominous and is made more so with this,

Chu said more than 90 per cent of the firefighters who responded to the 9/11 disaster developed lung disease, having walked into a site full of small and very damaging particles in the air.

“Those nanoparticles go deep into your lungs and cause inflammation and other problems,” Chu said.

It seems odd to mention this particular disaster. The lung issues for the firefighters, first responders and people living close to the site of World Trade Centers collapse are due to a complex mix of materials in the air. Most of the research I can find focuses on micrsoscale particles such as the work from the University of California at Davis’s Delta Group (Detection and Evaluation of the Long-Range Transport of Aerosols). From the Group’s World Trade Center webpage,

The fuming World Trade Center debris pile was a chemical factory that exhaled pollutants in particularly dangerous forms that could penetrate deep into the lungs of workers at Ground Zero, says a new study by UC Davis air-quality experts.

You can find the group’s presentation (-Presentation download (WTC aersols ACS 2003.ppt; 7,500kb)) to an American Chemical Society meeting in 2003 along more details such as this on their webpage,

The conditions would have been “brutal” for people working at Ground Zero without respirators and slightly less so for those working or living in immediately adjacent buildings, said the study’s lead author, Thomas Cahill, a UC Davis professor emeritus of physics and atmospheric science and research professor in engineering.

“Now that we have a model of how the debris pile worked, it gives us a much better idea of what the people working on and near the pile were actually breathing,” Cahill said. “Our first report was based on particles that we collected one mile away. This report gives a reasonable estimate of what type of pollutants were actually present at Ground Zero.

“The debris pile acted like a chemical factory. It cooked together the components of the buildings and their contents, including enormous numbers of computers, and gave off gases of toxic metals, acids and organics for at least six weeks.”

The materials found by this group were not at the nanoscale. In fact, the focus was then and subsequently on materials such as glass shards, asbestos, and metallic aerosols at the microscale, all of which can cause well documented health problems. No doubt effective monitoring would have been helpful It seems the critical issue in the early stages of the disaster was access to a respirator. Also, effective monitoring at later stages which did not seem to have happened would have been a good idea.

A 2004 (?) New York Magazine article by Jennifer Senior titled ‘Fallout‘ had this to say about the air content,

Here, today, is what we know about the dust and air at ground zero: It contained glass shards, pulverized concrete, and many carcinogens, including hundreds of thousands of pounds of asbestos, tens of thousands of pounds of lead, mercury, cadmium, dioxins, PCBs, and polycyclic aromatic hydrocarbons, or PAHs. It also contained benzene. According to a study done by the U.S. Geological Survey, the dust was so caustic in places that its pH exceeded that of ammonia. Thomas Cahill, a scientist who analyzed the plumes from a rooftop one mile away, says that the levels of acids, insoluble particles, high-temperature organic materials, and metals were in most cases higher in very fine particles (which can slip deep into the lungs) than anyplace ever recorded on earth, including the oil fires of Kuwait.

The article describes at some length the problems for first responders and for those who later moved back into their homes nearby the disaster site under the impression the air was clean.

Getting back to the nanoscale, there were carbon nanotubes (CNTs) present as this 2009 research paper, Case Report: Lung Disease in World Trade Center Responders Exposed to Dust and Smoke: Carbon Nanotubes Found in the Lungs of World Trade Center Patients and Dust Samples, noted in relation to a sample of seven patients,

It may well be the most frequent injury pattern in exposed patients with severe respiratory impairment. b) Interstitial disease was present in four cases (Patients A, B, C, and E), characterized by a generally bronchiolocentric pattern of interstitial inflammation and fibrosis of variable severity. The lungs of these patients contained large amounts of silicates, and three of them showed nanotubes.

…

CNT of commercial origin, common now, would not have been present in substantial numbers in the WTC complex before the disaster in 2001. However, the high temperatures generated during the WTC disaster as a result of the combustion of fuel in the presence of carbon and metals would have been sufficient to locally generate large numbers of CNT. This scenario could have caused the generation of CNT that we have noted in the dust samples and in the lung biopsy specimens.

Given that CNTs are more common now, it would suggest that a monitor for nanoscale materials such as Chu’s proposed equipment could be an excellent idea. Unfortunately, it’s not clear what Chu is trying to achieve as she appears to make a blunder in the article,

Chu said environmental agencies require testing to distinguish between particles equal to or less than 10 microns and smaller particles 2.5 microns or less.

“When we inhale we inhale both size particles but they go into different parts of the lung,” said Chu, who said research shows the smaller the particle the higher the toxicity. [emphasis mine] The monitor she has developed can detect particles as small as one micron and even less.

The word ‘nanoparticle’ is often used generically to include, CNTs, quantum dots, silver nanoparticles, etc. as Chu seems to be doing throughout the article. The only nanomaterial/nanoparticle that researchers agree unequivocally cause lung problems are long carbon nanotubes which resemble asbestos fibres. This is precisely the opposite of Chu’s statement.

For validation, you can conduct your own search or you can check Swiss toxicologist Harald Krug’s (mentioned in my Nanosafety research: a quality control issue posting of Oct. 30, 2014) statement that most health and safety research of nanomaterials and the resultant conclusions are problematic. But he too is unequivocal with regard long carbon nanotubes (from Krug’s study, Nanosafety Research—Are We on the Right Track?).

Comparison of instillation and inhalation experiments: instillation studies have to be carried out with relatively high local doses and, thus, more often meet overload conditions than inhalation studies. Transient inflammatory effects have been observed frequently in both types of lung exposure, irrespective of the type of ENMs used for the experiment. This finding suggests an unspecific particle effect; moreover, the biological response seems to be comparable to a scenario involving exposure to fine dust. Prominent exceptions are long and rigid carbon nanotube (CNT) bundles, which induce a severe tissue reaction (chronic inflammation) that may ultimately result in tumor formation. Overall, the evaluated studies showed no indication of a “nanospecific” effect in the lung. [from the Summary section; 2nd bulleted point]

You can find the Nanozen website here but there doesn’t appear to be any information on the site yet. These search terms ‘about’, ‘team’, ‘technology’, and ‘product’ yielded no results on website as of Oct. 30, 2014 at 1000 hours PDT.