Sunflowers in Fargo, North Dakota, USA.. This image was released by the Agricultural Research Service, the research agency of the United States Department of Agriculture, with the ID K5751-1 (Downloaded from Wikipedia; http://en.wikipedia.org/wiki/Sunflower)

I love the big sunflowers, the ones where the stalks extend many feet past my 5’4″ and which are topped with those improbable, lush, huge flowers. The flowers’ height always puts me in mind of trees. While scientists may appreciate the aesthetics and poetry as much as I do, their thoughts tend to turn to less fanciful matters. From the Aug. 16, 2012 news item on ScienceDaily,

A field of young sunflowers will slowly rotate from east to west during the course of a sunny day, each leaf seeking out as much sunlight as possible as the sun moves across the sky through an adaptation called heliotropism.

It’s a clever bit of natural engineering that inspired imitation from a UW-Madison electrical and computer engineer, who has found a way to mimic the passive heliotropism seen in sunflowers for use in the next crop of solar power systems.

Unlike other “active” solar systems that track the sun’s position with GPS and reposition panels with motors, electrical and computer engineering professor Hongrui Jiang’s concept leverages the properties of unique materials in concert to create a passive method of re-orienting solar panels in the direction of the most direct sunlight.

Here’s a demonstration of Jiang’s concept, not as a pretty as a sunflower, in a very bare bones video where you have to watch closely or you might miss the action,

Here’s a description of what you’re witnessing from Mark Reichers’ Aug. 15, 2012 news release for the University of Wisconsin-Madison,

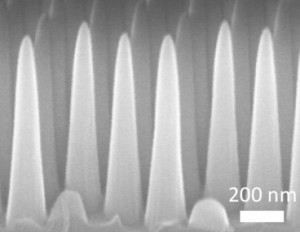

His design, published Aug. 1 in Advanced Functional Materials and recently highlighted in Nature, employs a combination of liquid crystalline elastomer (LCE), which goes through a phase change and contracts in the presence of heat, with carbon nanotubes, which can absorb a wide range of light wavelengths.

“Carbon nanotubes have a very wide range of absorption, visible light all the way to infrared,” says Jiang. “That is something we can take advantage of, since it is possible to use sunlight to drive it directly.”

Direct sunlight hits a mirror beneath the solar panel, focused onto one of multiple actuators composed of LCE laced with carbon nanotubes. The carbon nanotubes heat up as they absorb light, and the heat differential between the environment and inside the actuator causes the LCE to shrink.

This causes the entire assembly to bow in the direction of the strongest sunlight. As the sun moves across the sky, the actuators will cool and re-expand, and new ones will shrink, re-positioning the panel over the 180 degrees of sky that the sun covers in the course of the day.

This new approach improves solar panel efficiency by 10%. This is significant in a field where an increase of even a few percentage points is cause for celebration (my July 30, 2012 posting makes reference to this phenomenon of celebrating relatively small increases in solar power systems efficiencies).