Lomiko Metals issued a Feb. 9, 2016 news release (also received via email) about the latest graphite flake tests of its La Loutre property as it moves one step closer to acquiring 80% of the property,

Lomiko Metals Inc. (LMR.V) (LMRMF) (FSE:DH8B) and Canada Strategic Metals Inc. (CJC.V) (FSE:YXEN) (OTC Pink: CJCFF) (“Canada Strategic Metals”) are pleased to announce a Resource for the La Loutre Flake Graphite Property of 18.4 M Tonnes of 3.19% Indicated and 16.7 M Tonnes at 3.75% Flake Graphite Inferred with a cut-off of 1.5%.

The sensitivity table also features 4.1 M Tonnes of 6.5% Indicated and 6.2 M Tonnes at 6.1% Flake Graphite Inferred with a cut-off of 3%. The Resource is calculated on the Graphene-Battery Zone only and does not include recent high grade intercepts of 28.5 metres of 16.53% Cg and 21.5 metres of 11.53% Cg reported January 6, 2016 and 9% over 90.75 metres reported September 24th, 2015 from the Refractory Zone.

The La Loutre property consists of contiguous claim blocks totalling approximately 2,867.29 hectares (28.67 km2) situated approximately 53 km east of Imerys Carbon and Graphite, formerly known as the Timcal Graphite Mine, North America’s only operating graphite mine, and 117 km northwest of the International Port of Montreal, key to shipping to North America and Europe. Lomiko is currently completing an option to acquire 80% of the property which requires $665,000 more in work and issuing of 1.5 Million shares to be issue February 15th, 2016. [emphasis mine]

…

“The La Loutre Property is located close to the Imerys Carbon and Graphite Mine and benefits from similar infrastructure advantages and similar flake graphite grade, deposit size and near surface mineralization amenable to low cost, small footprint extraction. All of these elements make this an excellent candidate for a positive PEA”, stated A. Paul Gill, CEO, Lomiko Metals Inc., “Lomiko is proceeding with the PEA immediately.”

“We are very pleased with the results from the first resource estimate performed on the La Loutre property. The results from this resource estimate clearly demonstrate the strong potential for future development on the property, particularly with all the infrastructure around the project and the proximity with the Imerys Carbon mine. With 20% carry interest in the project, we hope to be able to leverage our interest to develop our others assets.”, stated Jean-Sébastien Lavallée, President &CEO, Canada Strategic Metals, “We are very excited by the decision to move the project forward to PEA level in the coming months.”

The La Loutre Resource is constrained within a drilled area of approximately 900 m along the N150 degrees striking trend of the graphitic paragneiss, 250 m across the strike and 225 m below surface. Geological interpretation and estimation were based on 62 NQ drill holes (totaling 8,193.3 m) drilled by Lomiko and Canada Strategic Metals in 2014 and 2015.

InnovExplo performed the geological interpretation and correlated the mineralized zones on vertical sections spaced 50 metres apart. The mineralized-zone model was constructed to outline zones of continuous mineralization along an average trend of N150 degrees and an average dip of 45 degrees. A minimum width of 4.0 meters (true width) was respected for the interpretation model. InnovExplo constructed a mineralized-zone wireframe model delimiting the geologically defined extent of all mineralized zones. The 2016 Mineral resource Estimate includes 18 graphite-bearing zones grouping elevated graphite mineralization (assays > 4% Cg), 4 graphite-bearing zones containing low graphite grade (assays

The mineral resource was estimated using 3-D block modeling (block size = 5 m x 5 m x 5 m), with the grades of the blocks calculated using the inverse distance squared (ID2) interpolation method for a 1000-metre strike length corridor of the La Loutre deposit, down to a vertical depth of 180 metres below surface.

The resources are constrained in a Pit shell of 1,100 m by 350 m by 100 m maximal depth.

…

The Independent and Qualified Persons for the Mineral Resource Estimate, as defined by NI 43-101, are Bruno Turcotte, M.Sc., P.Geo., and Guilhem Servelle, M.Sc., P.Geo, both of InnovExplo under the supervision of Vincent Jourdain, Ph.D., Eng., Technical Director of InnovExplo Inc.

The effective date of the estimate is January 15, 2016.

Mineral Resources are not Mineral Reserves and do not have demonstrated economic viability.

Pit constrained results are presented undiluted within a Whittle-optimized pit shell, designed with a 30-m buffer around lakes.

The estimate includes 18 graphite-bearing zones grouping elevated carbon graphite grade (assays > 4% Cg), 4 graphite-bearing zones containing low carbon graphite grade (assays

Pit constrained resources were compiled at cut-off grades of 0.5, 0.6, 0.8, 1.0, 1.5, 2.0, 2.5 and 3.0 % Cg. The official Pit constrained resource is reported at a cut-off grade of 1.5 % Cg.

Cut-off grades must be re-evaluated in light of prevailing market conditions (graphite price, exchange rate and mining cost).

Density (g/cm3) data used is on a per zone basis varying from 2.70 to 2.85 g/cm3.

A minimum true thickness of 4.0 m was applied, using the grade of the adjacent material when assayed, or a value of zero when not assayed.

Based on a study of the effect of high-grade values on the mean and standard deviations, as well as on log-normal histograms and probability plots, no raw assay was capped within the mineralized zones.

Compositing was done on drill hole sections falling within the mineralized zones (composite = 1.5 m).

Resources were estimated using GEOVIA GEMS 6.7 software from surface drill holes, using inverse distance squared (ID2) interpolation method in a block model (block size = 5 m x 5 m x 5 m).

By default, interpolated blocks were assigned to the Inferred category.

The reclassification to an Indicated category is defined in areas of spatial continuity in terms of information density visually observed and supported by the maximum distance to drill hole composites less than 30 m.

Calculations used metric units (metres, tonnes and %).

The number of metric tonnes was rounded to the nearest hundred. Any discrepancies in the totals are due to rounding effects; rounding followed the recommendations in NI 43-101.

InnovExplo is not aware of any known environmental, permitting, legal, title-related, taxation, socio-political, marketing or other relevant issue that could materially affect the mineral resource estimate.

Whittle parameters used (all amounts in Canadian dollars): Reference Mining cost=$3.75, milling cost=$9.40/t, G&A=$2.11/t, graphite price=$1,910/t, milling recovery=95%, wall slopes of 45 degrees in rock and 18 degrees in overburden.

QUALIFIED PERSONS

Jean-Sébastien Lavallée (OGQ #773), P. Geo, shareholder of both companies, President & CEO of Canada Strategic Metals and is Qualified Person as defined by National Instrument 43-101. Mr. Lavallée drafted, reviewed and approved the technical and scientific content of this press release, except for the content relating to the resource estimate.

This press release has been reviewed and approved by Bruno Turcotte, P. Geo, Guilhem Servelle, P. Geo., and Vincent Jourdain, Eng., who are qualified persons within the meaning of the National Instrument 43-101 guidelines.

The resource estimate was prepared under the supervision of Vincent Jourdain, an InnovExplo geoscientist and consulting engineer. Mr. Jourdain, an independent qualified person within the meaning of National Instrument 43-101, has reviewed and approved the technical content of this press release as it relates to the resource estimate.

For more information on Lomiko Metals, review the website at www.lomiko.com, …

On Behalf of the Board

“A. Paul Gill”

Chief Executive OfficerWe seek safe harbor. Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

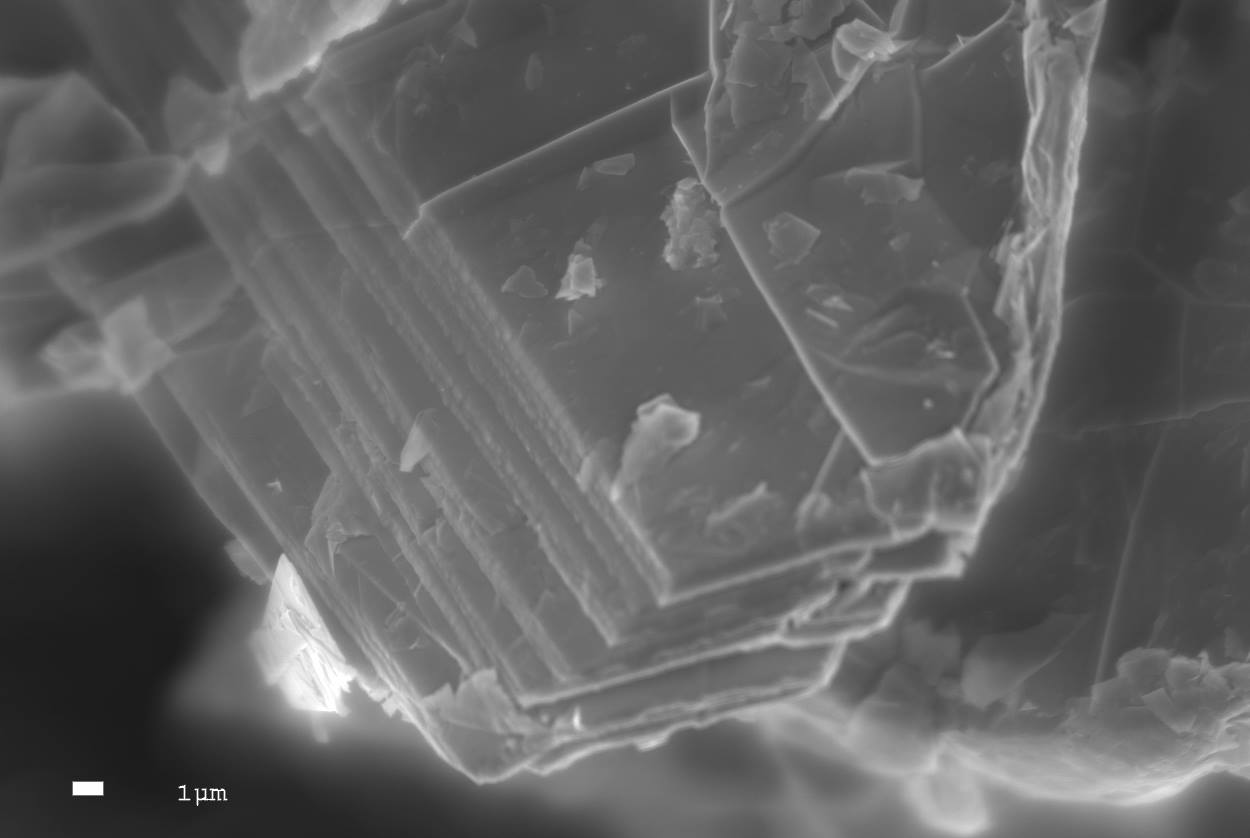

Here’s an image included with the news release,

As I don’t understand the analysis of the flake quality, this news release has little meaning for me (so this is not an endorsement) but I do note that Lomiko Metals does seem intent on developing the La Loutre property. Also, I am wondering about their Quatre Milles property (also graphite flakes) and with the company’s plans to enter the the 3D graphene printing market.

You can find out more about Canada Strategic Metals here and Innov Explo here.