Québec City’s (Canada) Musée de la Civilisation (Museum of Civilization) opened its “Nanotech: the invisible revolution” exhibit (also known as, “Nanotechnologies: l’invisible révolution”) on March 9, 2016 and it will run until April 2, 2016. Cassandra Kerwin’s March 16, 2016 article for qctonline.com notes this,

Featuring elements inspired by science fiction, comic books and today’s products and gadgets, it will have visitors wondering about the meaning and impact of infinitely small technology on daily life.

The Musée de la Civilisation’s Nanotech exhibit page has this to say,

Today’s “nanos” can be found in electronic gadgets, cosmetics, sports equipment, and medical treatments. Thousands more promising new applications are also on the way.

Nanotechnology has drawn on as well as influenced science fiction, sometimes in dark visions of a future world where humanity is at the mercy of developments in technology. Such future images can affect public perceptions. Debates have intensified, and in the last few decades enthusiasm for scientific discoveries has increasingly given way to a certain wariness.

Visitors will be encouraged to make up their own minds about current issues in nanotech development.

Perhaps ‘nanos’ is from the French? It’s here in the French language Musée de la Civilisation’s March 8, 2016 news release (my rough translation follows the sections I’ve created in this excerpt),

Les nanos sont présentes, par exemple, dans les appareils électroniques, les cosmétiques, les équipements sportifs et les traitements médicaux. Elles promettent des milliers de nouvelles utilisations intéressantes. Souvent inspirées par la science-fiction, les nanotechnologies revêtent parfois, dans des mondes futuristes, un caractère sombre où l’humain est à la merci des développements technologiques. Au cours des dernières décennies, l’enthousiasme généré par les découvertes scientifiques a laissé une place grandissante à une certaine méfiance du public face à la science, souvent dûe à une méconnaissance des notions scientifiques parfois complexes liées à ces découvertes. Le scepticisme relié aux changements climatiques ou encore à l’efficacité ou la sécurité des vaccins en sont des exemples concrets.

Nanotechnology-enabled products can be found everywhere, for example, in electronics, beauty projects, sporting goods, and biomedical applications. Nanotechnology also promises novel applications for the future. As sometimes depicted in science fiction. nanotechnology features in a dystopian future where humans are at the mercy of technological development. Over the last decades, the enthusiasm earlier generations showed for scientific discovery has given rise to distrust sometimes due to not understanding the science underlying the discovery. Examples of this distrust include climate change deniers and anti-vaccine proponents.

« Le Musée de la civilisation fait figure de modèle inspirant en muséologie, non seulement par ses approches et ses concepts audacieux, mais aussi par ses actions en périphérie comme sa mission éducative auprès des jeunes et ses projets de médiation culturelle. En ouvrant son espace au « nanomonde », le musée devient un point de convergence de la culture et de la science, ces deux piliers fondateurs de l’évolution de notre société. Le fait de démocratiser la science dans un lieu culturel à la portée d’un large public est indéniablement profitable », a déclaré le ministre de la Culture et des Communications et ministre responsable de la Protection et de la Promotion de la langue française, M. Luc Fortin.

“The museum is an inspiring museology model not only due to its audacious concepts but also because of activities such as youth education programmes and cultural outreach efforts. In devoting an exhibition to the ‘nanoworld’, the museum becomes a point of convergence for culture and science, two foundational pillars of evolution for society. Democratizing and making science accessible to the public at large though a cultural institution is undeniably profitable,” declared the Luc Fortin, Minister of Culture and Communication and the Minister Responsible for the Protection and Promotion of the French Language.

« Voilà un sujet qui convient bien au Musée de la civilisation. Ni musée d’histoire, ni musée de science, ni musée d’anthropologie ou d’ethnologie, ni musée d’art, mais un heureux amalgame de tout ça. Un musée de société dont la préoccupation première demeure l’être humain et ses questionnements, a souligné son directeur général, M. Stéphan La Roche. Dans cette exposition, réalité, science et fiction se côtoient habilement et, au cœur du propos, se trouve cet être humain appelé à s’interroger sur les innombrables impacts sociaux des nanotechnologies », a conclu M. La Roche.

« Nous sommes très fiers d’avoir contribué à la réalisation de cette exposition, a soutenu Pierre Lapointe, président et directeur général de FPInnovations, et nous sommes très heureux du résultat. Nous sommes persuadés que le public fera de grandes découvertes et qu’il sera surpris des possibilités qu’offrent les nanotechnologies, notamment dans le domaine de la foresterie. »

« Les nanotechnologies recèlent un immense potentiel d’innovation et de développement social et économique pour le Québec, a affirmé Benoit Balmana, président et directeur général de PRIMA QUÉBEC. Cette exposition met en évidence des développements d’applications extraordinaires tout en n’occultant pas les risques et les facteurs d’acceptation sociale. C’est une occasion unique de confronter le monde scientifique, industriel et la société pour assurer un développement responsable des innovations technologiques. »

« Au Québec, nous avons acquis une expertise reconnue mondialement en matière de nanotechnologies, et pour nous démarquer encore davantage dans ce secteur, nous devons poursuivre nos efforts en recherche et en innovation, favoriser le transfert technologique et tout mettre en œuvre pour développer une relève scientifique », a déclaré Rémi Quirion, ph. D., scientifique en chef du Québec. « Cette formidable exposition contribuera assurément à mieux faire connaître du grand public les nanotechnologies, et ce, dans toutes leurs dimensions : de la technologie à ses applications sociales, notamment dans le domaine de la santé, en passant par les enjeux éthiques. Elle incitera sûrement des jeunes intéressés par les carrières scientifiques à se tourner vers cet univers aussi prometteur que fascinant. »

Quotes from various dignitaries and important people which can be summarized as: “This is a wonderful exhibit and we (the province of Quebec, our organization, and/or the museum) are doing wonderful things.”

Le parcours du visiteur : oui ou non aux nanos?

Après une brève introduction sur les nanotechnologies, le visiteur est invité à prendre position face aux enjeux actuels liés au développement des nanotechnologies. Deux parcours sont possibles : oui ou non au développement des nanotechnologies dans le futur? Pour accompagner le visiteur et valider ses choix, un petit canard jaune en plastique muni d’une puce est mis à sa disposition.

Oui aux nanos!

Avec ces choix de parcours, on présente les espoirs générés par le développement des nanos et comment elles ont inspiré des auteurs de science-fiction. On y découvre aussi comment elles sont présentes dans notre vie quotidienne. Ici, figurine de Cora Peterson (Raquel Welch) du film Le voyage fantastique, sculpture d’Iron Man grandeur nature, série de processeurs, produits cosmétiques… illustrent l’intégration des nanotechnologies dans des univers réels ou imaginaires.

Non aux nanos!

Faisant contrepoids à l’enthousiasme face au développement des nanotechnologies, le volet non aux nanos présente les craintes qu’elles soulèvent : les incertitudes quant à leur présence dans notre quotidien et les risques potentiels pour la santé et l’environnement. Ici, on retrouve des figurines, des bandes dessinées ou des éléments associés à l’univers de la science-fiction (Terminator, Hulk…), une combinaison de protection pour laboratoire de nanotechnologies, des téléphones cellulaires de différentes époques…

Faire un choix… à l’aide d’un canard jaune!

À divers moment dans l’exposition, des énoncés sont émis incitant le visiteur à faire son choix. Ceux-ci abordent l’intégration des technologies au corps humain, l’utilisation des nanos pour le développement de l’électronique ou les traitements médicaux, la potentielle domination sur l’humain, souvent illustrée en science-fiction et qui suscite bien des inquiétudes. En fin de parcours, le visiteur remet son petit canard jaune. Ses résultats individuels sont ensuite compilés et livrés sous forme d’analyse graphique. Il peut ensuite voir les résultats globaux de tous les visiteurs ayant fait le parcours sur un écran de diffusion.

After a brief introduction to the concept of nanotechnology, I believe they’re saying the exhibit represents two basic views: ‘yes to nano’ and ‘no to nano’ and the visitor is invited to participate by means of a yellow duck (in English sometimes referred to familiarly as a “yellow rubber ducky”) with a computer chip.

In the ‘yes to nano corner’, hopes and dreams for the future inspired by science fiction are presented along with the examples of the current presence of nanotechnology-enabled products in our daily lives. Illustrating these themes of the imaginary and the real are figures of Cora Peterson (Raquel Welch) in Fantastic Voyage and an Iron Man figure along with computer processors and cosmetic products.

In the ‘no to nano corner’ risks to the environment and health and safety are represented both through such cautionary science fiction tales as Terminator, the Hulk, and others along with real life concerns in laboratories.

At different points in the exibit, visitors will be asked to make a choice (vote) with their yellow duck as to, for example, whether we should integrate technology into the body and whether nanotechnology should be used to further develop electronics or medical applications. Concerns about technological domination over human existence are also raised.

As the visit is ended, participants hand off their yellow ducks so their votes can be tallied and added to a data visualization which shows the results of all the visitors’ data on a screen.

Un peu d’histoire

Le centre de l’exposition aborde l’histoire et l’évolution des sciences qui a permis d’atteindre l’échelle du nanomètre avant de mettre en valeur quelques projets de recherche prometteurs en nanotechnologies au Québec. On découvre notamment que, depuis des siècles, la nature utilise des propriétés particulières de l’échelle nanométrique pour conférer des habiletés extraordinaires et des couleurs magnifiques à certains animaux. Dans le même esprit, on apprend que les humains, à leur insu, ont utilisé des propriétés de cette échelle donnant des caractéristiques uniques à certains objets comme des vitraux médiévaux et des sabres de Damas au tranchant redoutable. Enfin, quelques projets de recherche prometteurs en nanotechnologies au Québec sont mis en valeur.

Part of this show focuses on the history of science and how we became able to research and work at the nanoscale. There’s a reference to nature which has used nanoscale structures to colour birds in brilliant colours and given other animals extraordinary abilities. [There is a field known as biomimicry/bioinspired engineering/biomimetics which focuses on nature’s nanostructures.] It should also be noted that humans have (naïvely) made use of nanoscale properties in materials such as the stained glass windows in medieval churches and Damascus steel blades. The exhibit also showcases some current nanotechnology research from Québec.

Un défi de taille!

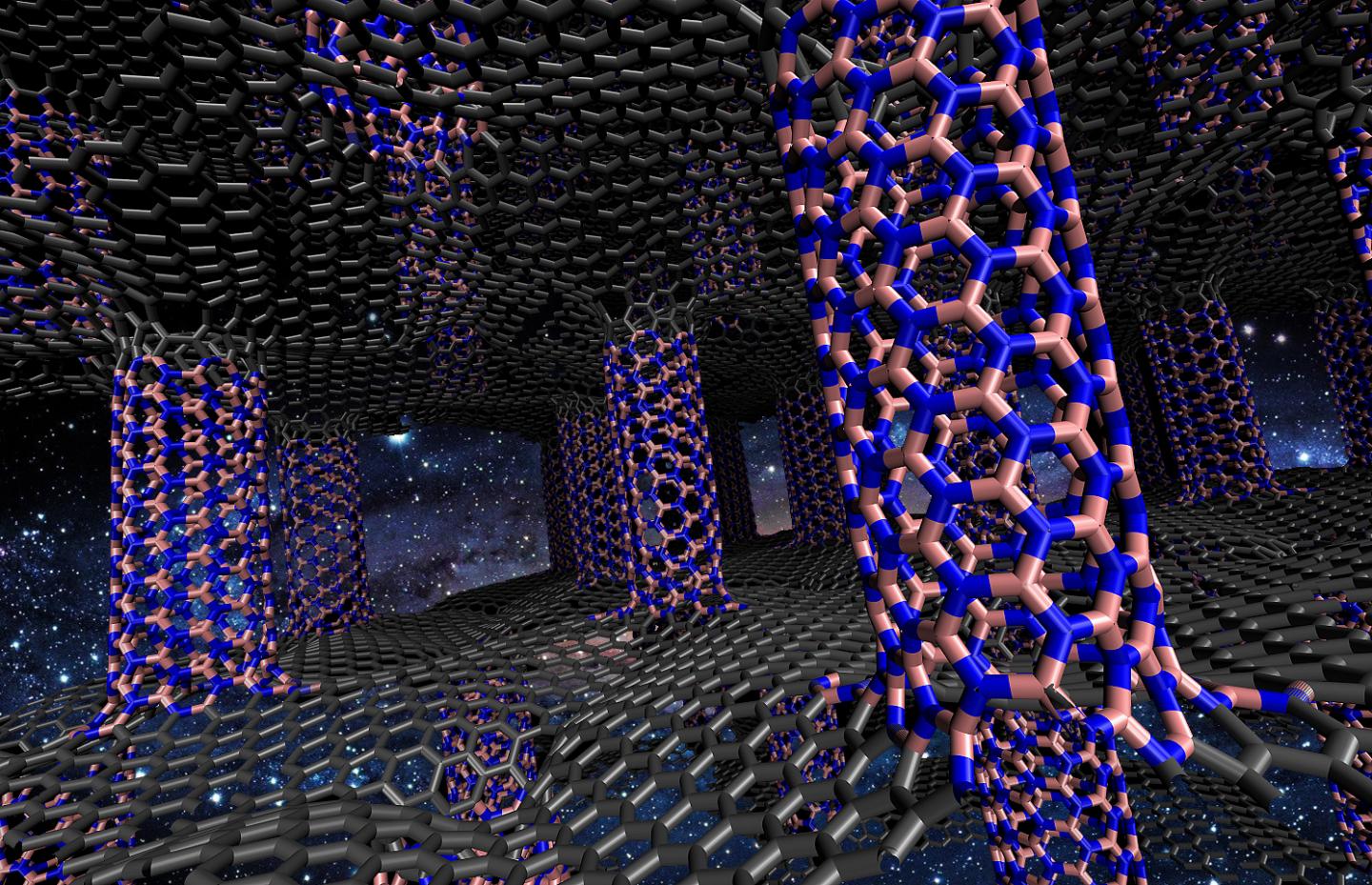

Comment montrer l’infiniment petit? L’objet-même de l’exposition pose un défi de taille! Néanmoins, des objets de nature diverse et visibles à l’œil nu appuient le propos : objets de collection tirés de l’univers de la science-fiction, objets du quotidien contenant des nanoparticules, modèles moléculaires, microscopes, espèces de la faune qui utilisent des propriétés nanos pour raffiner leur anatomie (tels des papillons et deux geckos vivants). À ces objets extrêmement variés s’ajoutent des interactifs, des audiovisuels, des illustrations et une installation du biologiste et artiste François-Joseph Lapointe qui reflète votre niveau de stress du moment.

Size presents this challenge: how to create an exhibit of the infinitely small? The answer was to include science fiction elements and figures, nanotechnology-enabled consumer products, models of molecules, microscopes, fauna that utilize nanoscale properties such as butterflies and two geckos. There are also audio visual materials, illustrations, and an installation by biologist and artist, François-Joseph Lapointe.

Autour de l’exposition

Des activités de médiation éducative sont offertes autour de l’exposition dès le 19 mars prochain. Le Musée propose des visites commentées et une animation à partir de l’installation Nanozen de l’artiste et biologiste François-Joseph Lapointe. À compter de septembre, des visites de l’exposition et des activités d’expérimentation et de réflexion seront offertes aux groupes scolaires. Enfin, des activités de médiation culturelle complèteront la programmation, dont une table-ronde intitulée Nano où es-tu?, présentée le 7 mai dans le cadre des 24 heures de science.

As of March 19, 2016 there are ancillary educational programmes such as tours and the Nanozen installation by François-Joseph Lapointe. And in September 2016, school tours will be offered. In the realm of culture programming, a roundtable discussion titled (literally): Nano where are you? (I think they mean: What is your position on Nano?) on May 7, 2016 as part of the 24 hours of science 2016 event.

Nanotechnologies : l’invisible révolution, au Musée de la civilisation à Québec, du 9 mars 2016 au 2 avril 2017. Une exposition conçue et réalisée par le Musée de la civilisation avec la participation de PRIMA QUÉBEC et ses partenaires : Fonds de recherche du Québec (FRQ), FPInnovations, Centre de Collaboration MiQro Innovation (C2MI), Centre de recherche industriel du Québec (CRIQ), École Polytechnique de Montréal, Institut de recherche Robert-Sauvé en santé et en sécurité du travail (IRSST), Institut national de la recherche scientifique (INRS), Université Concordia, Université de Montréal, Université du Québec à Montréal, Université Laval, Université McGill, Université de Sherbrooke et Arboranano.

The exhibit runs from March 9, 2016 – April 2, 2017 and a list of donors follows.

There’s information about tickets and hours here (the top price is $16 for an adult ticket).

Should anyone have a better translation please do let me know in the comments section.