It seems wearable electronic textiles may be getting nearer to the marketplace. I have three research items (two teams working with graphene and one working with carbon nanotubes) that appeared on my various feeds within two days of each other.

UK/China

This research study is the result of a collaboration between UK and Chinese scientists. From a May 15, 2019 news item on phys.org (Note: Links have been removed),

Wearable electronic components incorporated directly into fabrics have been developed by researchers at the University of Cambridge. The devices could be used for flexible circuits, healthcare monitoring, energy conversion, and other applications.

The Cambridge researchers, working in collaboration with colleagues at Jiangnan University in China, have shown how graphene – a two-dimensional form of carbon – and other related materials can be directly incorporated into fabrics to produce charge storage elements such as capacitors, paving the way to textile-based power supplies which are washable, flexible and comfortable to wear.The research, published in the journal Nanoscale, demonstrates that graphene inks can be used in textiles able to store electrical charge and release it when required. The new textile electronic devices are based on low-cost, sustainable and scalable dyeing of polyester fabric. The inks are produced by standard solution processing techniques.

Building on previous work by the same team, the researchers designed inks which can be directly coated onto a polyester fabric in a simple dyeing process. The versatility of the process allows various types of electronic components to be incorporated into the fabric.

A May 16, 2019 University of Cambridge press release, which originated the news item, probes further,

Most other wearable electronics rely on rigid electronic components mounted on plastic or textiles. These offer limited compatibility with the skin in many circumstances, are damaged when washed and are uncomfortable to wear because they are not breathable.

“Other techniques to incorporate electronic components directly into textiles are expensive to produce and usually require toxic solvents, which makes them unsuitable to be worn,” said Dr Felice Torrisi from the Cambridge Graphene Centre, and the paper’s corresponding author. “Our inks are cheap, safe and environmentally-friendly, and can be combined to create electronic circuits by simply overlaying different fabrics made of two-dimensional materials on the fabric.”

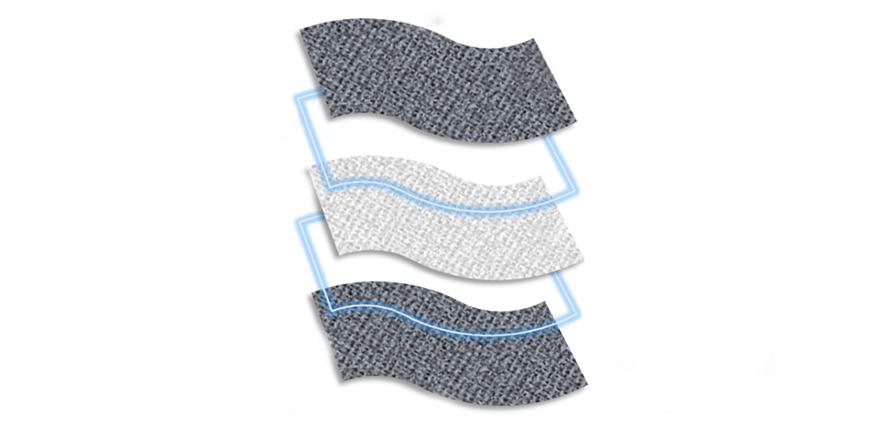

The researchers suspended individual graphene sheets in a low boiling point solvent, which is easily removed after deposition on the fabric, resulting in a thin and uniform conducting network made up of multiple graphene sheets. The subsequent overlay of several graphene and hexagonal boron nitride (h-BN) fabrics creates an active region, which enables charge storage. This sort of ‘battery’ on fabric is bendable and can withstand washing cycles in a normal washing machine.

“Textile dyeing has been around for centuries using simple pigments, but our result demonstrates for the first time that inks based on graphene and related materials can be used to produce textiles that could store and release energy,” said co-author Professor Chaoxia Wang from Jiangnan University in China. “Our process is scalable and there are no fundamental obstacles to the technological development of wearable electronic devices both in terms of their complexity and performance.”

The work done by the Cambridge researchers opens a number of commercial opportunities for ink based on two-dimensional materials, ranging from personal health and well-being technology, to wearable energy and data storage, military garments, wearable computing and fashion.

“Turning textiles into functional energy storage elements can open up an entirely new set of applications, from body-energy harvesting and storage to the Internet of Things,” said Torrisi “In the future our clothes could incorporate these textile-based charge storage elements and power wearable textile devices.”

Here’s a link to and a citation for the paper,

Wearable solid-state capacitors based on two-dimensional material all-textile heterostructures by Siyu Qiang, Tian Carey, Adrees Arbab, Weihua Song, Chaoxia Wang and Felice Torris. Nanoscale, 2019, Advance Article DOI: 10.1039/C9NR00463G First published on 18 Apr 2019

This paper is behind a paywall.

India

Prior to graphene’s reign as the ‘it’ carbon material, carbon nanotubes (CNTs) ruled. It’s been quieter on the CNT front since graphene took over but a May 15, 2019 Nanowerk Spotlight article by Michael Berger highlights some of the latest CNT research coming out of India,

…

The most important technical challenge is to blend the chemical nature of raw materials with fabrication techniques and processability, all of which are diametrically conflicting for textiles and conventional energy storage devices. A team from Indian Institute of Technology Bombay has come out with a comprehensive approach involving simple and facile steps to fabricate a wearable energy storage device. Several scientific and technological challenges were overcome during this process.First, to achieve user-comfort and computability with clothing, the scaffold employed was the the same as what a regular fabric is made up of – cellulose fibers. However, cotton yarns are electrical insulators and therefore practically useless for any electronics. Therefore, the yarns are coated with single-wall carbon nanotubes (SWNTs).

SWNTs are hollow, cylindrical allotropes of carbon and combine excellent mechanical strength with electrical conductivity and surface area. Such a coating converts the electrical insulating cotton yarn to a metallic conductor with high specific surface area. At the same time, using carbon-based materials ensures that the final material remains light-weight and does not cause user discomfort that can arise from metallic wires such as copper and gold. This CNT-coated cotton yarn (CNT-wires) forms the electrode for the energy storage device.

Next, the electrolyte is composed of solid-state electrolyte sheets since no liquid-state electrolytes can be used for this purpose. However, solid state electrolytes suffer from poor ionic conductivity – a major disadvantage for energy storage applications. Therefore, a steam-based infiltration approach that enhances the ionic conductivity of the electrolyte is adopted. Such enhancement of humidity significantly increases the energy storage capacity of the device.

…

The integration of the CNT-wire electrode with the electrolyte sheet was carried out by a simple and elegant approach of interweaving the CNT-wire through the electrolyte (see Figure 1). This resulted in cross-intersections which are actually junctions where the electrical energy can be stored. Each such junction is now an energy storage unit, referred to as sewcap.The advantage of this process is that several 100s and 1000s of sewcaps can be made in a small area and integrated to increase the total amount of energy stored in the system. This scalability is unique and critical aspect of this work and stems from the approach of interweaving.

Further, this process is completely adaptable with current processes used in textile industries. Hence, a proportionately large energy-storage is achieved by creating sewcap-junctions in various combinations.

All components of the final sewcap device are flexible. However, they need to be protected from environmental effects such as temperature, humidity and sweat while retaining the mechanical flexibility. This is achieved by laminating the entire device between polymer sheets. The process is exactly similar to the one used for protecting documents and ID cards.

The laminated sewcap can be integrated easily on clothing and fabrics while retaining the flexibility and sturdiness. This is demonstrated by the unchanged performance of the device during extreme and harsh mechanical testing such as striking repeatedly with a hammer, complete flexing, bending and rolling and washing in a laundry machine.

In fact, this is the first device that has been proven to be stable under rigorous washing conditions in the presence of hot water, detergents and high torque (spinning action of washing machine). This provides the device with comprehensive mechanical stability.

…

CNTs have high surface area and electrical conductivity. The CNT-wire combines these properties of CNTs with stability and porosity of cellulose yarns. The junction created by interweaving is essentially comprised of two such CNT-wires that are sandwiching an electrolyte. Application of potential difference leads to polarization of the electrolyte thus enabling energy storage similar to the way in which a conventional capacitor acts.“We use the advantage of the interweaving process and create several such junctions. So, with each junction being able to store a certain amount of electrical energy, all the junctions synchronized are able to store a large amount of energy. This provides high energy density to the device,” Prof. C. Subramaniam, Department of Chemistry, IIT Bombay and corresponding author of the paper points out.

The device has also been employed for lighting up an LED [light-emitting diode]. This can be potentially scaled to provide electrical energy demanded by the application.

…

This image accompanies the paper written by Prof. C. Subramaniam and his team,

Here’s a link to and a citation for the paper,

Interwoven Carbon Nanotube Wires for High-Performing, Mechanically Robust, Washable, and Wearable Supercapacitors by Mihir Kumar Jha, Kenji Hata, and Chandramouli Subramaniam. ACS Appl. Mater. Interfaces, Article ASAP DOI: 10.1021/acsami.8b22233 Publication Date (Web): April 29, 2019 Copyright © 2019 American Chemical Society

This paper is behind a paywall.

Canada

A research team from the University of British Columbia (UBC at the Okanagan Campus) joined the pack with a May 16, 2019 news item on ScienceDaily,

Forget the smart watch. Bring on the smart shirt.

Researchers at UBC Okanagan’s School of Engineering have developed a low-cost sensor that can be interlaced into textiles and composite materials. While the research is still new, the sensor may pave the way for smart clothing that can monitor human movement.

…

A May 16, 2019 UBC news release (also on EurekAlert), which originated the news item, describes the work in more detail,

“Microscopic sensors are changing the way we monitor machines and humans,” says Hoorfar, lead researcher at the Advanced Thermo-Fluidic Lab at UBC’s Okanagan campus. “Combining the shrinking of technology along with improved accuracy, the future is very bright in this area.”This ‘shrinking technology’ uses a phenomenon called piezo-resistivity—an electromechanical response of a material when it is under strain. These tiny sensors have shown a great promise in detecting human movements and can be used for heart rate monitoring or temperature control, explains Hoorfar.

Her research, conducted in partnership with UBC Okanagan’s Materials and Manufacturing Research Institute, shows the potential of a low-cost, sensitive and stretchable yarn sensor. The sensor can be woven into spandex material and then wrapped into a stretchable silicone sheath. This sheath protects the conductive layer against harsh conditions and allows for the creation of washable wearable sensors.

While the idea of smart clothing—fabrics that can tell the user when to hydrate, or when to rest—may change the athletics industry, UBC Professor Abbas Milani says the sensor has other uses. It can monitor deformations in fibre-reinforced composite fabrics currently used in advanced industries such as automotive, aerospace and marine manufacturing.

The low-cost stretchable composite sensor has also shown a high sensitivity and can detect small deformations such as yarn stretching as well as out-of-plane deformations at inaccessible places within composite laminates, says Milani, director of the UBC Materials and Manufacturing Research Institute.

The testing indicates that further improvements in its accuracy could be achieved by fine-tuning the sensor’s material blend and improving its electrical conductivity and sensitivity This can eventually make it able to capture major flaws like “fibre wrinkling” during the manufacturing of advanced composite structures such as those currently used in airplanes or car bodies.

“Advanced textile composite materials make the most of combining the strengths of different reinforcement materials and patterns with different resin options,” he says. “Integrating sensor technologies like piezo-resistive sensors made of flexible materials compatible with the host textile reinforcement is becoming a real game-changer in the emerging era of smart manufacturing and current automated industry trends.”

Here’s a link to and a citation for the paper,

Graphene‐Coated Spandex Sensors Embedded into Silicone Sheath for Composites Health Monitoring and Wearable Applications by Hossein Montazerian, Armin Rashidi, Arash Dalili, Homayoun Najjaran, Abbas S. Milani, Mina Hoorfar. Small Volume15, Issue17 April 26, 2019 1804991 DOI: https://doi.org/10.1002/smll.201804991 First published: 28 March 2019

This paper is behind a paywall.

Will there be one winner or will they find CNTs better for one type of wearable tech textile while graphene excels for another type of wearable tech textile?