A May 21, 2020 news item on Nanowerk describes the latest in sports self-monitoring research (or as I like to think of it, spying on yourself),

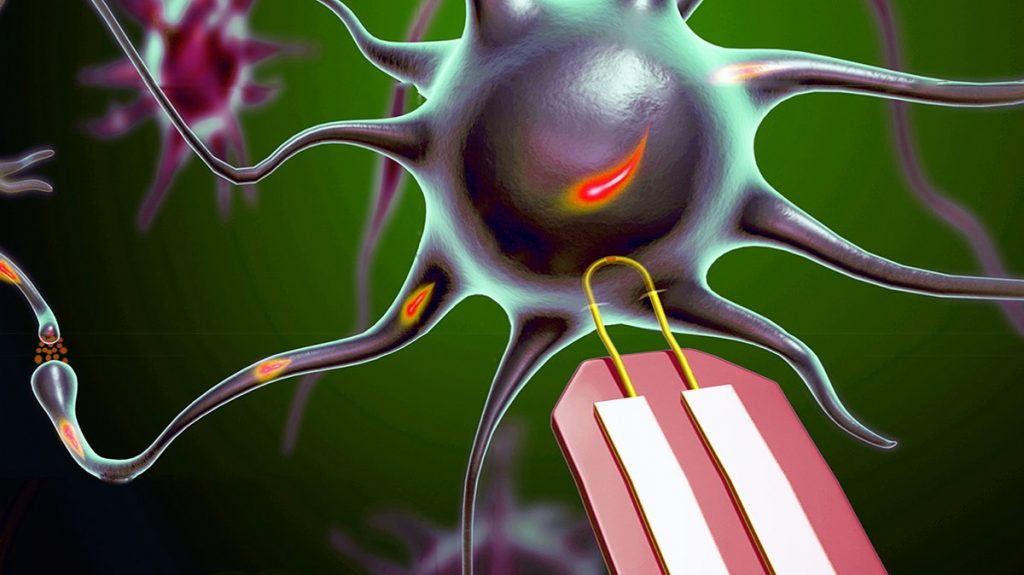

Researchers from the University of Surrey have revealed their new biodegradable motion sensor – paving the way for implanted nanotechnology that could help future sports professionals better monitor their movements to aid rapid improvements, or help caregivers remotely monitor people living with dementia.

…

A May 21, 12020 University of Surrey press release (also on EurekAlert), which originated the news item, mentioned the collaboration with a South Korean University and provides a few details about this work,

In a paper published by Nano Energy, a team from Surrey’s Advanced Technology Institute (ATI), in partnership with Kyung Hee University in South Korea, detail how they developed a nano-biomedical motion sensor which can be paired with AI systems to recognise movements of distinct body parts.

The ATI’s technology builds on its previous work around triboelectric nanogenerators (TENG), where researchers used the technology to harness human movements and generate small amounts of electrical energy. Combining the two means self-powered sensors are possible without the need for chemical or wired power sources.

In their new research, the team from the ATI developed a flexible, biodegradable and long-lasting TENG from silk cocoon waste. They used a new alcohol treatment technique, which leads to greater durability for the device, even under harsh or humid environments.

Dr. Bhaskar Dudem, project lead and Research Fellow at the ATI, said: “We are excited to show the world the immense potential of our durable, silk film based nanogenerator. It’s ability to work in severe environments while being able to generate electricity and monitor human movements positions our TENG in a class of its own when it comes to the technology.”

Professor Ravi Silva, Director of the ATI, said: “We are proud of Dr Dudem’s work which is helping the ATI lead the way in developing wearable, flexible, and biocompatible TENGs that efficiently harvest environmental energies. If we are to live in a future where autonomous sensing and detecting of pathogens is important, the ability to create both self-powered and wireless biosensors linked to AI is a significant boost.”

Here’s a link to and a citation for the paper,

Exploring theoretical and experimental optimization towards high-performance triboelectric nanogenerators using microarchitecture silk cocoon films by Bhaskar Dudem, R.D. Ishara G. Dharmasena, Sontyana Adonijah Graham, Jung Woo Leem, Harishkumarreddy Patnam, Anki Reddy Mule, S. Ravi P. Silva, Jae Su Yu. Nano Energy DOI: https://doi.org/10.1016/j.nanoen.2020.104882 Available online 11 May 2020, 104882

This paper is behind a paywall.