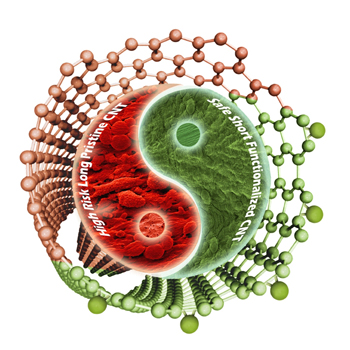

Illustration courtesy of the University College of London (UCL). Downloaded from http://www.ucl.ac.uk/news/news-articles/0113/130115-chemistry-resolves-toxic-concerns-about-carbon-nanotubes

Researchers at the University College of London (UCL), France’s Centre national de la recherche scientifique (CNRS), and Italy’s University of Trieste have determined that carbon nanotube toxicity issues can be addressed be reducing their length and treating them chemically. From the Jan. 15,2013 news item on ScienceDaily,

In a new study, published January 15 [2013] in the journal Angewandte Chemie, evidence is provided that the asbestos-like reactivity and pathogenicity reported for long, pristine nanotubes can be completely alleviated if their surface is modified and their effective length is reduced as a result of chemical treatment.

First atomically described in the 1990s, carbon nanotubes are sheets of carbon atoms rolled up into hollow tubes just a few nanometres in diameter. Engineered carbon nanotubes can be chemically modified, with the addition of chemotherapeutic drugs, fluorescent tags or nucleic acids — opening up applications in cancer and gene therapy.

Furthermore, these chemically modified carbon nanotubes can pierce the cell membrane, acting as a kind of ‘nano-needle’, allowing the possibility of efficient transport of therapeutic and diagnostic agents directly into the cytoplasm of cells.

Among their downsides however, have been concerns about their safety profile. One of the most serious concerns, highlighted in 2008, involves the carcinogenic risk from the exposure and persistence of such fibres in the body. Some studies indicate that when long untreated carbon nanotubes are injected to the abdominal cavity of mice they can induce unwanted responses resembling those associated with exposure to certain asbestos fibres.

In this paper, the authors describe two different reactions which ask if any chemical modification can render the nanotubes non-toxic. They conclude that not all chemical treatments alleviate the toxicity risks associated with the material. Only those reactions that are able to render carbon nanotubes short and stably suspended in biological fluids without aggregation are able to result in safe, risk-free material.

Here’s a citation and link for this latest research, from the ScienceDaily news item where you can also read the lead researcher’s comments about carbon nanotubes, safety, and unreasonable proposals to halt production,

Hanene Ali-Boucetta, Antonio Nunes, Raquel Sainz, M. Antonia Herrero, Bowen Tian, Maurizio Prato, Alberto Bianco, Kostas Kostarelos. Asbestos-like Pathogenicity of Long Carbon Nanotubes Alleviated by Chemical Functionalization. Angewandte Chemie International Edition, 2013; DOI: 10.1002/anie.201207664

The article is behind a paywall. I have mentioned long carbon nanotubes and their resemblance to asbestos fibres in several posts. The Oct. 26, 2009 posting [scroll down about 1/3 of the way] highlights research which took place after the study where mice had carbon nanotubes injected into their bellies; in this second piece of research they inhaled the nanotubes.

ETA Jan. 21, 2013: Dexter Johnson gives context and commentary about this latest research into long multiwalled nanotubes (MWNTs) which he sums up as the answer to this question “What if you kept the MWNTs short?” in a Jan. 18, 2013 posting on his Nanoclast blog (on the IEEE [Institute of Electrical and Electronics Engineers] website)