They’re usually known as cellulose nanocrystals (CNCs) but the term wood nanocrystals works too. From a March 23, 2023 news item on Nanowerk,

Researchers at Chalmers University of Technology, Sweden, have developed a new method that can easily purify contaminated water using a cellulose-based material. This discovery could have implications for countries with poor water treatment technologies and combat the widespread problem of toxic dye discharge from the textile industry.

Clean water is a prerequisite for our health and living environment, but far from a given for everyone. According to the World Health Organization, WHO, there are currently over two billion people living with limited or no access to clean water.

This global challenge is at the centre of a research group at Chalmers University of Technology, which has developed a method to easily remove pollutants from water. The group, led by Gunnar Westman, Associate Professor of Organic Chemistry focuses on new uses for cellulose and wood-based products and is part of the Wallenberg Wood Science Center.

The researchers have built up solid knowledge about cellulose nanocrystals* – and this is where the key to water purification lies. These tiny nanoparticles have an outstanding adsorption capacity, which the researchers have now found a way to utilise.

“We have taken a unique holistic approach to these cellulose nanocrystals, examining their properties and potential applications. We have now created a biobased material, a form of cellulose powder with excellent purification properties that we can adapt and modify depending on the types of pollutants to be removed,” says Gunnar Westman.

…

A March 23, 2023 Chalmers University of Technology press release (also on EurekAlert), which originated the news item, describes the water treatment in more detail including how it will be tested in field conditions,

Absorbs and breaks down toxins

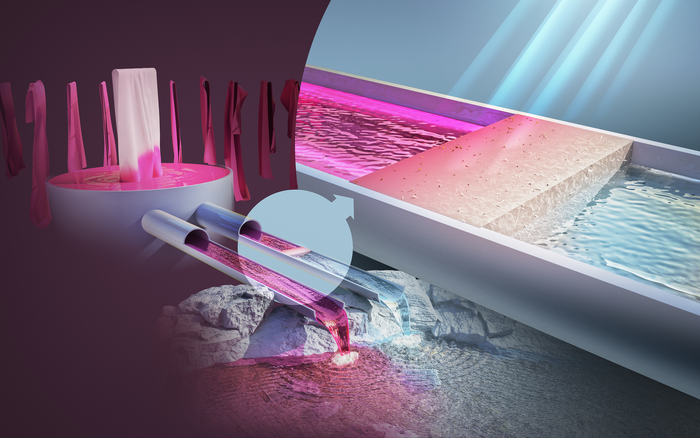

In a study recently published in the scientific journal Industrial & Engineering Chemistry Research, the researchers show how toxic dyes can be filtered out of wastewater using the method and material developed by the group. The research was conducted in collaboration with the Malaviya National Institute of Technology Jaipur in India, where dye pollutants in textile industry wastewater are a widespread problem.The treatment requires neither pressure nor heat and uses sunlight to catalyse the process. Gunnar Westman likens the method to pouring raspberry juice into a glass with grains of rice, which soak up the juice to make the water transparent again.

“Imagine a simple purification system, like a portable box connected to the sewage pipe. As the contaminated water passes through the cellulose powder filter, the pollutants are absorbed and the sunlight entering the treatment system causes them to break down quickly and efficiently. It is a cost-effective and simple system to set up and use, and we see that it could be of great benefit in countries that currently have poor or non-existent water treatment,” he says.

The method will be tested in India

India is one of the developing countries in Asia with extensive textile production, where large amounts of dyes are released into lakes, rivers and streams every year. The consequences for humans and the environment are serious. Water contaminant contains dyes and heavy metals and can cause skin damage with direct contact and increase the risk of cancer and organ damage when they enter into the food chain. Additionally, nature is affected in several ways, including the impairment of photosynthesis and plant growth.Conducting field studies in India is an important next step, and the Chalmers researchers are now supporting their Indian colleagues in their efforts to get some of the country’s small-scale industries to test the method in reality. So far, laboratory tests with industrial water have shown that more than 80 percent of the dye pollutants are removed with the new method, and Gunnar Westman sees good opportunities to further increase the degree of purification.

“Going from discharging completely untreated water to removing 80 percent of the pollutants is a huge improvement, and means significantly less destruction of nature and harm to humans. In addition, by optimising the pH and treatment time, we see an opportunity to further improve the process so that we can produce both irrigation and drinking water. It would be fantastic if we can help these industries to get a water treatment system that works, so that people in the surrounding area can use the water without risking their health,” he says.

Can be used against other types of pollutants

Gunnar Westman also sees great opportunities to use cellulose nanocrystals for the treatment of other water pollutants than dyes. In a previous study, the research group has shown that pollutants of toxic hexavalent chromium, which is common in wastewater from mining, leather and metal industries, could be successfully removed with a similar type of cellulose-based material. The group is also exploring how the research area can contribute to the purification of antibiotic residues.“There is great potential to find good water purification opportunities with this material, and in addition to the basic knowledge we have built up at Chalmers, an important key to success is the collective expertise available at the Wallenberg Wood Science Center,” he says.

More about the scientific article

Read the full article in Industrial & Engineering Chemistry Research: Cellulose nanocrystals derived from microcrystalline cellulose for selective removal of Janus Green Azo Dye. The authors of the article are Gunnar Westman and Amit Kumar Sonker of Chalmers University of Technology, and Ruchi Aggarwal, Anjali Kumari Garg, Deepika Saini, and Sumit Kumar Sonkar of Malaviya National Institute of Technology Jaipur in India. The research is funded by the Wallenberg Wood Science Center, WWSC and the Indian group research is funded by Science and Engineering Research Board under Department of Science and Technology (DST-SERB) Government of India.*Nanocrystals

Nanocrystals are nanoparticles in crystal form that are extremely small: a nanoparticle is between 1 and 100 nanometres in at least one dimension, i.e. along one axis. (one nanometre = one billionth of a metre).Wallenberg Wood Science Center

• The Wallenberg Wood Science Center, WWSC, is a research centre that aims to develop new sustainable biobased materials using raw materials from the forest. The WWSC is a multidisciplinary collaboration between Chalmers University of Technology, KTH Royal Institute of Technology and Linköping University, and is based on a donation from the Knut and Alice Wallenberg Foundation.

• The centre involves about 95 researchers and faculty members and 50 doctoral students. Eight research groups from Chalmers are part of the centre.About dye pollutants and access to clean water

• Over two billion people in the world live with limited or no access to clean water. It is estimated that over 3.5 million people die each year from lack of access to clean water and proper sanitation.

• The global textile industry, which is concentrated in Asia, contributes to widespread water pollution. Production often takes place in low-wage countries, where much of the technology is antiquated and environmental legislation and oversight may be lacking.

• Emissions contribute to eutrophication and toxic effects in water and soil. There are examples in China and India where groundwater has been contaminated by dye and processing chemicals.

• Producing one kilogram of new textiles requires between 7,000 and 29,000 litres of water, and between 1.5 and 6.9 kg of chemicals.

• In 2021, around 327 thousand tonnes of dyes and pigments were produced in India. A large proportion of the country’s dye pollutants is discharged untreated.…

Sources

Swedish Environmental Protection Agency: https://www.naturvardsverket.se/amnesomraden/textil/dagens-textila-floden-ar-en-global-miljoutmaning/

WHO: https://www.who.int/news-room/fact-sheets/detail/drinking-water

A critical review on the treatment of dye-containing wastewater: Ecotoxicological and health concerns of textile dyes and possible remediation approaches for environmental safety. Ecotoxicology and Environmental Safety, February 2022

https://www.sciencedirect.com/science/article/pii/S0147651321012720

Effects of textile dyes on health and the environment and bioremediation potential of living organisms. Biotechnology Research and Innovation, July–December 2019

https://www.sciencedirect.com/science/article/pii/S2452072119300413

Swedish Chemicals Agency: https://www.kemi.se/kemiska-amnen-och-material/nanomaterial

Even though there’s a link to the research in the press release, here’s my link to and citation for the paper, which specifies a particular dye suggesting this is not a universal treatment,

Cellulose Nanocrystals Derived from Microcrystalline Cellulose for Selective Removal of Janus Green Azo Dye by Ruchi Aggarwal, Anjali Kumari Garg, Deepika Saini, Sumit Kumar Sonkar, Amit Kumar Sonker, and Gunnar Westman. Ind. Eng. Chem. Res. 2023, 62, 1, 649–659 DOI: https://doi.org/10.1021/acs.iecr.2c03365 Publication Date: December 26, 2022 Copyright © 2022 American Chemical Society

This paper is behind a paywall.