An October 17, 2022 news item on phys.org highlights nanocellulose research from Brazil, Note: A link has been removed,

A research team affiliated with the Laboratory of Polymeric Materials and Biosorbents at the Federal University of São Carlos (UFSCar) in Araras, São Paulo state, Brazil, has produced and is testing cellulose-based materials for enhanced-efficiency fertilizers to improve the supply of nutrients to crops and reduce the release of non-biodegradable chemicals [forever chemicals] into the ecosystem.

The studies were led by Roselena Faez, a professor at the Center for Agricultural Sciences (CCA-UFSCar). The findings have recently been reported in two publications. One is an article published in Carbohydrate Polymers, with Débora França as first author. Here [keep scrolling down] the researchers describe how they used modified nanocellulose to discharge the nutrients contained in fertilizer into the soil slowly and in a controlled manner, given that nitrogen, phosphorus and potassium are highly soluble.

…

An October 19, 2022 Fundação de Amparo à Pesquisa do Estado de São Paulo [FAPESP] press release (also on EurekAlert but published October 17, 2022) by Karina Ninni, originated the phys.org news item. The researchers explain (Note: Links have been removed),

“Potassium is rapidly washed away by rain because of its high ion mobility. It’s the hardest to release in a controlled manner. Nitrogen can be obtained from various sources, such as nitrates, ammonia and urea, but plants get the nitrogen they need most easily from nitrate, which is also easily washed away and doesn’t remain in the soil for long. Phosphorus [as phosphate] is a very large ion and less mobile than the other macronutrients,” said Faez, who coordinates the Polymeric Materials and Biosorbents Research Group at UFSCar Araras.

Controlled-release products are available on the market, she added, but most are made of synthetic polymers, which are non-biodegradable. “Fertilizer grains are about the size of grains of coarse sea salt. To make sure the nutrients are released slowly, they’re coated with layers of polymer that last about two months each, so the manufacturer applies two, three or four coats, according to the desired length of time for controlled release,” Faez explained, noting that the polymers in question are plastics and remain in the soil, eventually degrading into microparticles that last virtually forever.

The researchers at UFSCar developed an entirely different product in which the chemical reaction between the modified nanocellulose and mineral salts keeps the nutrients in the soil. “We focused on the worst problems, which are nitrate and potassium. The material we developed is totally biodegradable and releases these nutrients at about the same slow rate as the available synthetic materials,” Faez said.

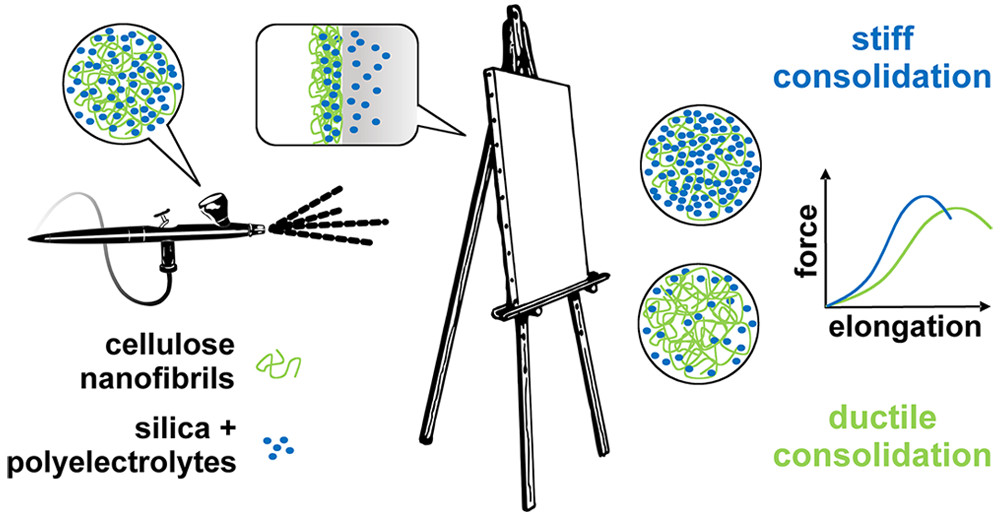

The nanocellulose was obtained from pure cellulose donated by a paper factory. The nanofibrils were functionalized with positive and negative charges to enhance polymer-nutrient interaction. “Because the salts are also made up of positively or negatively charged particles and highly soluble, we hypothesized that negatively charged nanocellulose would react with positive ions in the salts, while positively charged nanocellulose would interact with negative ions, reducing the solubility of the salts. This proved to be the case, and the group succeeded in modulating nutrient release in accordance with the type of particle in the material,” França said.

Evaluation in soil

The group fabricated the product in the form of tablets and evaluated its performance in terms of nutrient release into the soil. Evaluation of release into water is the usual method, and water is a very different system from soil. This part of the research was conducted in partnership with Claudinei Fonseca Souza, a professor at CCA-UFSCar’s Department of Natural Resources and Environmental Protection in Araras.

“We evaluated nutrient release into the soil and biodegradation of the material at the site for 100 days. But we deliberately used very poor soil with little organic matter, because this enables us to see the physical effects of release more easily,” Faez said.

The researchers used two techniques to obtain tablets: atomization and spray drying to encapsulate the nutrients with the nanocellulose, followed by heat processing of the resulting powder, which was pressed in a mold. This work was completed with the help of colleagues at the Cellulose and Wood Materials Laboratory belonging to EMPA (Swiss Federal Laboratories for Materials Science and Technology) and in collaboration with UFSCar’s Water, Soil and Environment Engineering Research Group, led by Souza. França performed the cellulose modifications at EMPA while on an internship there with support from FAPESP. She was also supported by a doctoral scholarship in Brazil.

Self-fertilization

The second recent article by the group was published in Industrial Crops and Products, with chemist Lucas Luiz Messa as first author. The goal of the study was to extract cellulose from sugarcane bagasse and modify it with a surface negative charge by phosphorylation (addition of a phosphorus group) to allow controlled release of potassium. In theory, delivery of plant nutrition would be slowed by cellulose phosphorylation, which would create surface anionic charges that would bind to macronutrient and micronutrient cations.

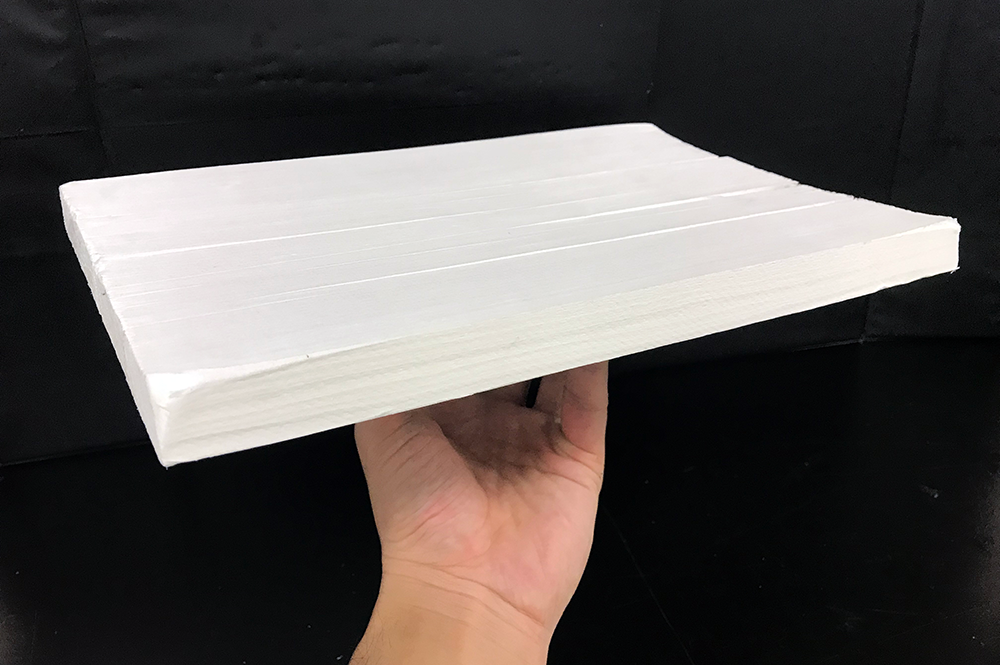

The group prepared three types of structure with the phosphorylated cellulose: oven-dried paper-like film; spray-dried powder; and freeze-dried porous bulk similar to polystyrene foam. Freeze drying, or lyophilization, was seen to leave nutrients in the voids left by water removal.

“Technologically speaking, the paper-like structure was the best material we produced for controlled delivery of nutrients. Several products can be created using this paper,” Faez said.

The results obtained in the research led by Messa enabled the group to develop small propagation pots for seedling cultivation. When this material degrades, the phosphorus it contains is released. According to Faez, cellulose phosphorylation is cheap, and the cost of the end product is relatively low. “It’s more or less BRL 0.27 per gram of paper produced. The propagation pot must be about 1 gram. Unit cost is therefore about BRL 0.30 in terms of laboratory costs,” she said.

Biodegradable propagation pots are already available on the market. “But our product has built-in fertilizer, which is a major competitive advantage. Indeed, we’ve filed a patent application,” she said.

The pot is about to be trialed by a flower producer in Holambra, São Paulo state. Several batches produced in the laboratory have been shipped there. Nutrient release has so far been tested only in water. “We call this an accelerated ion release assessment method because it’s faster in water, but even in water we found the release rate to be 40%-50% slower compared with the behavior of the ion in the material and without the material. Even in water, therefore, we succeeded in retaining these ions. We assume delivery will be even slower in the substrate,” she said.

The research was also supported by FAPESP via a Doctoral Scholarship in Brazil and a Research Internship Abroad Scholarship awarded to Messa, and a Regular Research Grant awarded to Faez.

Messa was assisted by a colleague at the University of California Davis (USA), where he worked as a research intern.

About São Paulo Research Foundation (FAPESP)

The São Paulo Research Foundation (FAPESP) is a public institution with the mission of supporting scientific research in all fields of knowledge by awarding scholarships, fellowships and grants to investigators linked with higher education and research institutions in the State of São Paulo, Brazil. FAPESP is aware that the very best research can only be done by working with the best researchers internationally. Therefore, it has established partnerships with funding agencies, higher education, private companies, and research organizations in other countries known for the quality of their research and has been encouraging scientists funded by its grants to further develop their international collaboration. You can learn more about FAPESP at www.fapesp.br/en and visit FAPESP news agency at www.agencia.fapesp.br/en to keep updated with the latest scientific breakthroughs FAPESP helps achieve through its many programs, awards and research centers. You may also subscribe to FAPESP news agency at http://agencia.fapesp.br/subscribe

I have links and citations for both papers mentioned in the press release,

Sugarcane bagasse derived phosphorylated cellulose as substrates for potassium release induced by phosphates surface and drying methods by Lucas Luiz Messa, You-Lo Hsieh, Roselena Faez. Industrial Crops and Products Volume 187, Part A, 1 November 2022, 115350 DOI: https://doi.org/10.1016/j.indcrop.2022.115350 Available online 20 July 2022, Version of Record 20 July 2022

This paper is behind a paywall.

Charged-cellulose nanofibrils as a nutrient carrier in biodegradable polymers for enhanced efficiency fertilizers by Débora França, Gilberto Siqueira, Gustav Nyström, Frank Clemens, Claudinei Fonseca Souza, Roselena Faez. Carbohydrate Polymers Volume 296, 15 November 2022, 119934 DOI: https://doi.org/10.1016/j.carbpol.2022.119934 Available online 1 August 2022, Version of Record 3 August 2022

This paper is behind a paywall.