I have two news bits about Alberta’s nanotechnology scene, one focused on a hockey logo (this year [2017], there are two Canadian teams [Edmonton Oilers and Ottawa Senators] competing to get to the finals and a Stanley Cup win sometime in June; there hasn’t been a win by a Canadian team since 1993); the other news bit concerns funding for research into technology for oil spill cleanups.

National Hockey League (NHL) logo

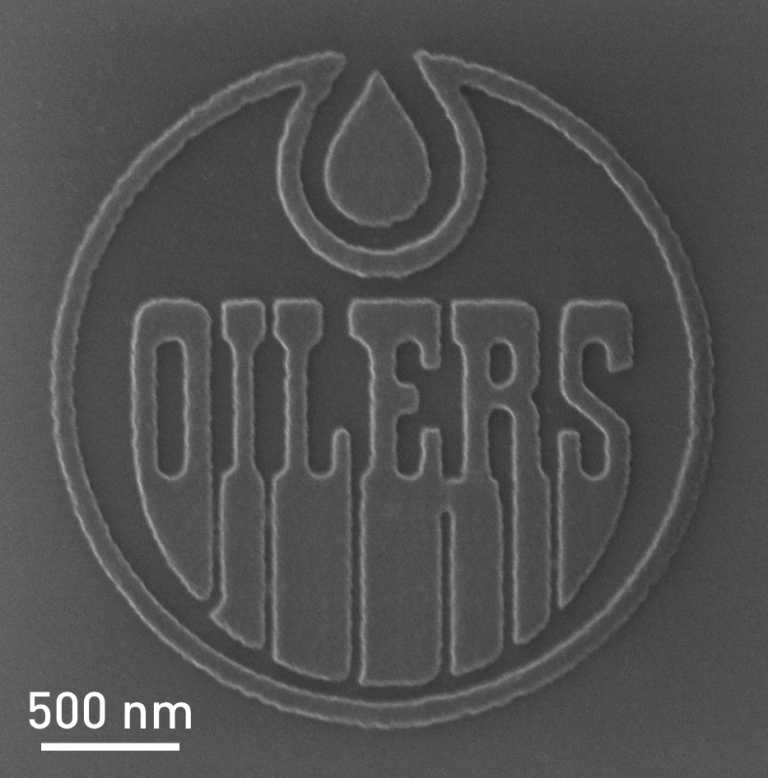

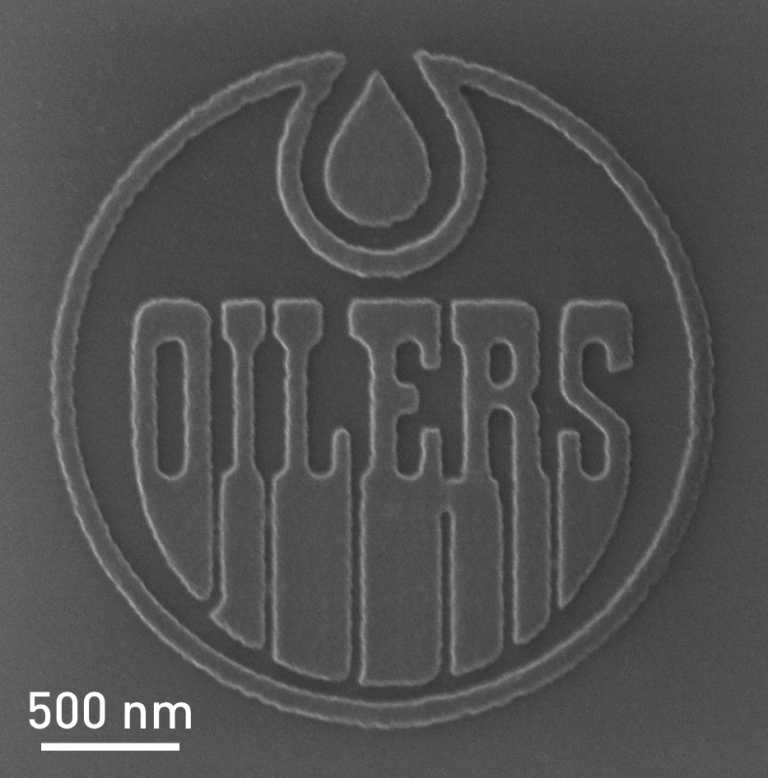

To celebrate the Edmonton Oilers entry into the semifinals, folks at the University of Alberta have created the smallest NHL logo for them. From a May 1, 2017 news item by Chad Mosleh for Metro News Edmonton,

A department at the University of Alberta has created an Oilers logo so small you could fit 900 million of them on top of a puck.

“We’re constantly trying to push the limit of how small we can make things,” said Eric Flaim, director of the NanoFAB Fabrication & Characterization Centre, which focuses on research on micro and nanoscale units, which are particles so tiny you need an extremely powerful microscope to see them.

The microscopic Oilers logo was created in collaboration with Edmonton-based companies Applied Quantum Materials and Applied Nanotools. The logo is 2.4 micrometres in diameter, 40 times smaller than a similar one they made in 2006, which was roughly the width of a human hair. The university is calling it the world’s smallest NHL logo.

[downloaded from https://www.nanofab.ualberta.ca/2017/news/lets-go-oilers/]

An

April 27, 2017 posting by Dr. Eric Flaim for the University of Alberta’s nanoFAB blog notes this (Note: Links have been removed),

Working in partnership with two Edmonton companies who are developing new nanoscale fabrication processes to support commercialization of made-in-Alberta technology for photonics, sensors, and nanomaterials, the nanoFAB took the opportunity to show pride in our Edmonton Oilers.

Using a nanomaterial developed by Applied Quantum Materials, and nanoscale pattern correction methods developed by Applied Nanotools, we thought it would be fitting to re-create the logo we fabricated during the Oilers’ last playoff run…albeit at a much smaller scale.

Whereas the Oilers logo in 2006 was about the width of a human hair, the logo we made for this year’s Orange Crush is over 40× smaller: at only 2.4 µm in diameter, over 900 million of these logos could fit on top of a hockey puck.

Beyond showing team spirit, the fabrication of this logo highlights several of the unique capabilities available at the nanoFAB. The logo was fabricated via electron-beam lithography (EBL) with our Raith 150-TWO system, using AQM SIOX as the EBL resist—a made-in-Edmonton alternative to the ultra-high resolution hydrogen silsesquioxane (HSQ) resist. At such a small length scale, sophisticated pattern correction techniques must be used to ensure the fidelity of the design; this expertise was provided by engineers from Applied Nanotools, who use the same methods for their high-resolution silicon photonics service. Finally, the images of the logos were taken using our Zeiss Orion NanoFab Helium Ion microscope.

I wonder how the University of Ottawa and the Ottawa Senators team are responding to this development?

Oil spills and carbon nanotube (CNT) meshes

An April 28, 2017 Ingenuity Lab news release (which rather weirdly has London, England listed as the location in the dateline) on MarketWired announces Canadian federal government funding for a project centered in Alberta, Canada,

Nanotechnology has had a multitude of applications: from healthcare to textiles to new consumer gadgets, innovative new uses for nanotechnology are constantly emerging. It has now found a new role, with University of Alberta-based nanotechnology accelerator Ingenuity Lab using it as the basis for the development of a revolutionary new way to clean up oil spills. The system has received a vote of confidence from Natural Resources Canada, with the organization providing $1.7m to fund its ongoing development.

Using a carbon-nanotube mesh combined with other minerals and polymers, Ingenuity Lab’s system acts as a sponge that attracts and absorbs oil underwater. When it is fully saturated with oil, the mesh is then removed from the water and exposed to heat, electricity or ultraviolet light, causing it to expel the collected oil.

The oil spill cleaning system has come a long way in a remarkably short amount of time. Director of Ingenuity Lab Dr Carlo Montemango [sic] said his team was able to demonstrate the effectiveness of the membrane approximately a year ago, but is now working on developing a large-scale version of the system. “Where you might see it is being rolled off the back [of a vessel] and dragged or moved through the water. As it becomes saturated, it would be brought on board, the oil would be expelled and it would be redeployed.”

Past tests have shown the system can be remarkably effective and is capable of cleaning up 100 percent of a spill – even the heavier oil that may be trapped below the surface. The system also recovers the oil, allowing it to be reused and potentially recuperate some of the cost associated with cleaning up a spill.

The technology is far more advanced than current methods of containing a spill, which usually involve floating booms and skimming oil from the water’s surface. Ingenuity Lab’s system would make a substantial difference should the world see another event on the scale of the 2010 Deepwater Horizon disaster, or the Exxon Valdez spill of 1989.

This is by no means the first nanotechnology project Ingenuity Lab has worked on. Other projects have looked at capturing carbon emissions, healthcare and agriculture.

Montemango [sic] said the team is now working on developing a pilot system and beginning field tests in less than two years. “Our mission is to develop solutions to significant societal problems and challenges, and translate those solutions to the marketplace.”

I searched for more information about the new funding and found this news release (?) on the Ingenuity Lab website,

Oil is a common pollutant in oceans; more than three million metric tons of oil contaminate them every year. The accidental release of crude oil into a body of water by an oil tanker, refinery, storage facility, underwater pipeline, or offshore oil-drilling rig, is an environmental emergency. Depending on location, oil spills can be both hazardous as well as environmentally destructive. Timely cleanup is critical to protecting the integrity of the water, the shoreline, and the creatures that depend on these habitats. Due to increased scrutiny of the oil industry (with regards to its environmental record) the attention has focused on the development of new materials and technologies for removing organic contaminants; including spilled oil from waterways. Since existing methods are not sufficiently robust, nanotechnology has initiated the development of new tools using specifically designed materials suited for separations, such as the removal of crude oil from water.

Ingenuity Lab, a multidisciplinary research initiative based in Alberta, received $1.7 million in project funding for the research and development of an effective alternative for recovering heavy oil spilled in marine environments. IngenuityLab developed nanowire-based multifunctional stimuli-responsive membranes and devices capable of recovering the oil from spills.

This project will focus on the recovery of oil through the development of novel technology and devices using a variety of stimuli-responsive nanomaterials. The fabrication of reinforced membranes for oil-water separation (published in Adv. Mater. Interfaces, 2016, 3: 1600445) [emphasis mine] uses carbon nanotubes (CNTs), mats, and a few other metal oxide embedded nanowire hybrid membranes. They exhibit the switchable hydrophobic property with the influence of stimuli (UV, heat, electric, etc.). The focus of using the membranes is to develop a pilot facility for separating the oil out of spills to clean the environment while recovering the valuable oils.

Here’s a link to and a citation for the paper I highlighted in the news release (?),

Electric Field Induced Switchable Wettability to Water on the Polyaniline Membrane and Oil/Water Separation by Xi Zheng, Zhenyan Guo, Dongliang Tian, Xiaofang Zhang, and Lei Jiang. Advanced Materials Interfaces Volume 3, Issue 18, September 20, 2016 DOI: 10.1002/admi.201600461 Version of Record online: 7 JUL 2016

© 2016 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

This paper is behind a paywall.

I have a few comments about this work. it’s encouraging to see these efforts to develop better technologies for cleaning up oil spills but it does seem that none of these proposed solutions ever makes it out of the laboratory. For example, I have an April 17, 2012 posting about CNT nanosponges that absorb oil and which could be wrung out and reused. More recently, I had a Dec. 7, 2015 posting featuring boron nitride nanosponges (or nanosheets) for oil spill cleanups. Personally, I prefer sponges that can be wrung out over meshes or sponges that need additional processing such as exposure ” … to heat, electricity or ultraviolet light … .” Regardless, I hope one of these days, a new oil spill cleanup technology will make its way into the field.

For those not familiar with Alberta and the oil industry, the province is a main source for the fossil fuel and, in particular, the Alberta oil sands, which environmentalists have uncategorically condemned.

![[downloaded from http://pubs.acs.org/doi/abs/10.1021/acs.langmuir.6b01743]](http://www.frogheart.ca/wp-content/uploads/2016/07/KazanUni_Oil-degradingBacteria.gif)