Citrus greening is a worldwide problem. A particularly virulent disease that destroys citrus fruit, it’s a problem that is worsening. Before getting to the research from the University of California at Riverside (UCR), here’s more about the disease and how it’s developing from the UCR Huanglongbing, (HLB, Citrus Greening webpage,

The Situation: Citrus huanglongbing (HLB), previously called citrus greening disease, is one of the most destructive diseases of citrus worldwide. Originally thought to be caused by a virus, it is now known to be caused by unculturable phloem-limited bacteria. There are three forms of greening that have been described. The African form produces symptoms only under cool conditions and is transmitted by the African citrus psyllid Trioza erytreae, while the Asian form prefers warmer conditions and is transmitted by the Asian citrus psyllid Diaphorina citri. Recently a third American form transmitted by the Asian citrus psyllid was discovered in Brazil. This American form of the disease apparently originated in China. In North America, the psyllid vector, Diaphorina citri, of HLB is found in Florida, Louisiana, Georgia, South Carolina, Texas and Hawaii, and recently arrived in Southern California from Mexico. HLB is known to occur in Florida Lousiana, South Carolina, Georgia, Cuba, Belize and the Eastern Yucatan of Mexico. A federal quarantine restricts all movement of citrus and other plants in the family Rutaceae from Asian Citrus Psyllid or HLB-infested areas into California in order to prevent introduction of the disease.

Damage: The HLB bacteria can infect most citrus cultivars, species and hybrids and even some citrus relatives. Leaves of newly infected trees develop a blotchy mottle appearance. On chronically infected trees, the leaves are small and exhibit asymmetrical blotchy mottling (in contrast to Zinc deficiency that causes symmetrical blotching). Fruit from HLB-infected trees are small, lopsided, poorly colored, and contain aborted seeds. The juice from affected fruit is low in soluble solids, high in acids and abnormally bitter. The fruit retains its green color at the navel end when mature, which is the reason for the common name “citrus greening disease.” This fruit is of no value because of poor size and quality. There is no cure for the disease and rapid tree removal is critical for prevention of spread.

Economic Impact: HLB is one of the most devastating diseases of citrus and since its discovery in Florida in 2005, citrus acreage in that state has declined significantly. If the disease were to establish in California, the nursery industry would be required to move all of their production under screenhouses, pesticide treatments for the vector would be instituted resulting in greatly increased pesticide costs (3-6 treatments per year) and indirect costs due to pesticide-induced disruption of integrated pest management programs for other citrus pests. A costly eradication program would need to be instituted to remove infected trees in order to protect the citrus industry.

Distribution of HLB: In April 2012, after about a week of testing, the California Department of Food and Agriculture (CDFA) removed a pumelo tree with a lemon graft from Hacienda Heights in Los Angeles County after the tree and an Asian citrus psyllid found on the tree both tested positive for Huanglongbing. In 2005, HLB was also found in Florida and it is now known to occur in Louisiana, Georgia, South Carolina, Cuba, Belze and Eastern Mexico. Worldwide, HLB is also present in China, eastern and southern Africa, the Indian subcontinent, Mauritius, Reunion, the Saudi Arabian peninsula, and southeast Asia.

Research: Research is focusing on characterization of the bacteria, development of detection methods, and control of the disease and the psyllid. To date, control of the disease is based on planting HLB-free citrus germplasm, eradication of infected citrus plants, and control of the vector with systemic insecticides. Countries with HLB learn to manage the disease so that they can still produce citrus. In California, the best strategy is to keep this disease out. This goal is supported by both federal and state quarantine regulations and the University of California’s Citrus Clonal Protection Program, which provides a mechanism for the safe introduction of citrus germplasm into California.

…

A July 7, 2020 news item on phys.org announces what researchers hope can be used commercially as a new treatment for citrus greening disease from researchers University of California at Riverside (UCR), Note: Links have been removed,

UC Riverside scientists have found the first substance capable of controlling Citrus Greening Disease, which has devastated citrus farms in Florida and also threatens California.

The new treatment effectively kills the bacterium causing the disease with a naturally occurring molecule found in wild citrus relatives. This molecule, an antimicrobial peptide, offers numerous advantages over the antibiotics currently used to treat the disease.

UCR geneticist Hailing Jin, who discovered the cure after a five-year search, explained that unlike antibiotic sprays, the peptide is stable even when used outdoors in high heat, easy to manufacture, and safe for humans.

A July 7, 2020 UCR news release (also on EurekAlert) by Jules Bernstein, which originated the news item, provides technical detail and information about plans to commercialize the product,

“This peptide is found in the fruit of Australian finger limes, which can naturally tolerate Citrus Greening bacteria and has been consumed for hundreds of years,” Jin said. “It is much safer to use this natural plant product on agricultural crops than other synthetic chemicals.”

Currently, some growers in Florida are spraying antibiotics and pesticides in an attempt to save trees from the CLas bacterium that causes citrus greening, also known as Huanglongbing or HLB.

“Most antibiotics are temperature sensitive, so their effects are largely reduced when applied in the hot weather,” Jin said. “By contrast, this peptide is stable even when used in 130-degree heat.”

Jin found the peptide by examining plants such as the Australian finger lime known to possess natural tolerance for the bacteria that causes Citrus Greening Disease, and she isolated the genes that contribute to this innate immunity. One of these genes produces the peptide, which she then tested over the course of two years. Improvement was soon visible.

“You can see the bacteria drastically reduced, and the leaves appear healthy again only a few months after treatment,” Jin said.

Because the peptide only needs to be reapplied a few times per year, it is highly cost effective for growers. This peptide can also be developed into a vaccine to protect young healthy plants from infection, as it is able to induce the plant’s innate immunity to the bacteria.

Jin’s peptide can be applied by injection or foliage spray, and it moves systemically through plants and remains stable, which makes the effect of the treatment stronger.

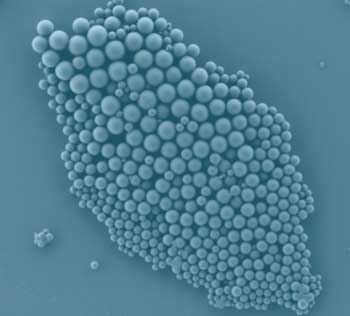

The treatment will be further enhanced with proprietary injection technology made by Invaio Sciences. UC Riverside has entered into an exclusive, worldwide license agreement with Invaio, ensuring this new treatment goes exactly where it’s needed in plants.

“Invaio is enthusiastic to partner with UC Riverside and advance this innovative technology for combating the disease known as Citrus Greening or Huanglongbing,” said Invaio Chief Science Officer Gerardo Ramos. “The prospect of addressing this previously incurable and devastating crop disease, helping agricultural communities and improving the environmental impact of production is exciting and rewarding,” he said. “This is crop protection in harmony with nature.”

The need for an HLB cure is a global problem, but hits especially close to home as California produces 80 percent of all the fresh citrus in the United States, said Brian Suh, director of technology commercialization in UCR’s Office of Technology Partnerships, which helps bring university technology to market for the benefit of society through licenses, partnerships, and startup companies.

“This license to Invaio opens up the opportunity for a product to get to market faster,” Suh said. “Cutting edge research from UCR, like the peptide identified by Dr. Jin, has a tremendous amount of commercial potential and can transform the trajectory of real-world problems with these innovative solutions.”

You can find out more about Invaio Sciences here.

Citrus greening has been featured here before in an April 7, 2015 posting titled, Citrus canker, Florida, and Zinkicide. There doesn’t seem to have been much progress made with this Florida solution for citrus greening. This 2018 document on nano.gov was the most recent I could find, ZinkicideTM- a systemic nano-ZnO based bactericide/fungicide for crop protection by Swadeshmukul Santra.