Most people don’t realize how much energy computing, streaming video, and other technologies consume and AI (artificial intelligence) consumes a lot. (For more about work being done in this area, there’s my October 13, 2023 posting about an upcoming ArtSci Salon event in Toronto featuring Laura U. Marks’s recent work ‘Streaming Carbon Footprint’ and my October 16, 2023 posting about how much water is used for AI.)

So this news is welcome, from an October 12, 2023 Northwestern University news release (also received via email and on EurekAlert), Note: Links have been removed,

AI just got 100-fold more energy efficient

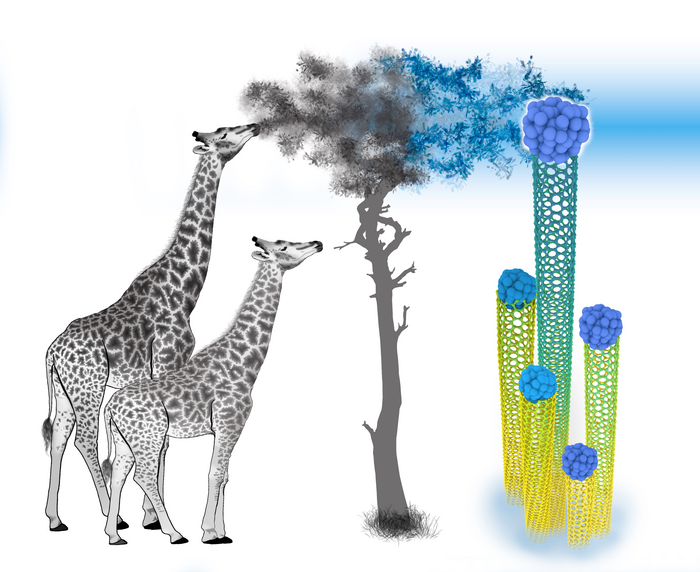

Nanoelectronic device performs real-time AI classification without relying on the cloud

– AI is so energy hungry that most data analysis must be performed in the cloud

– New energy-efficient device enables AI tasks to be performed within wearables

– This allows real-time analysis and diagnostics for faster medical interventions

– Researchers tested the device by classifying 10,000 electrocardiogram samples

– The device successfully identified six types of heart beats with 95% accuracyNorthwestern University engineers have developed a new nanoelectronic device that can perform accurate machine-learning classification tasks in the most energy-efficient manner yet. Using 100-fold less energy than current technologies, the device can crunch large amounts of data and perform artificial intelligence (AI) tasks in real time without beaming data to the cloud for analysis.

With its tiny footprint, ultra-low power consumption and lack of lag time to receive analyses, the device is ideal for direct incorporation into wearable electronics (like smart watches and fitness trackers) for real-time data processing and near-instant diagnostics.

To test the concept, engineers used the device to classify large amounts of information from publicly available electrocardiogram (ECG) datasets. Not only could the device efficiently and correctly identify an irregular heartbeat, it also was able to determine the arrhythmia subtype from among six different categories with near 95% accuracy.

The research was published today (Oct. 12 [2023]) in the journal Nature Electronics.

“Today, most sensors collect data and then send it to the cloud, where the analysis occurs on energy-hungry servers before the results are finally sent back to the user,” said Northwestern’s Mark C. Hersam, the study’s senior author. “This approach is incredibly expensive, consumes significant energy and adds a time delay. Our device is so energy efficient that it can be deployed directly in wearable electronics for real-time detection and data processing, enabling more rapid intervention for health emergencies.”

A nanotechnology expert, Hersam is Walter P. Murphy Professor of Materials Science and Engineering at Northwestern’s McCormick School of Engineering. He also is chair of the Department of Materials Science and Engineering, director of the Materials Research Science and Engineering Center and member of the International Institute of Nanotechnology. Hersam co-led the research with Han Wang, a professor at the University of Southern California, and Vinod Sangwan, a research assistant professor at Northwestern.

Before machine-learning tools can analyze new data, these tools must first accurately and reliably sort training data into various categories. For example, if a tool is sorting photos by color, then it needs to recognize which photos are red, yellow or blue in order to accurately classify them. An easy chore for a human, yes, but a complicated — and energy-hungry — job for a machine.

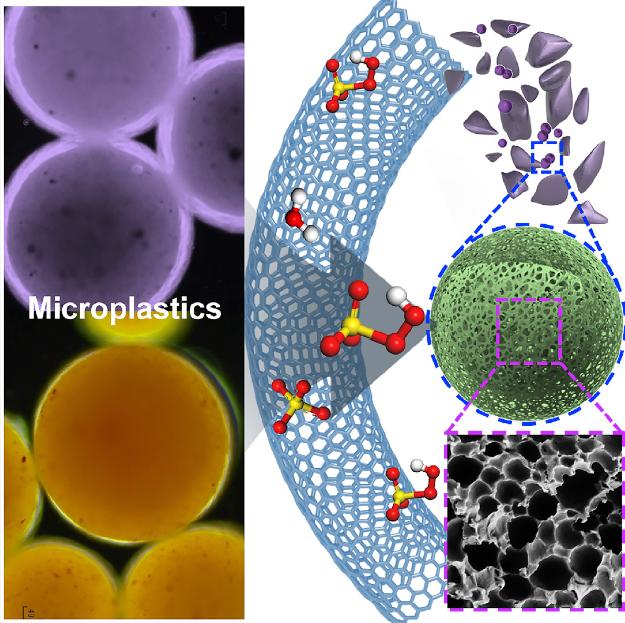

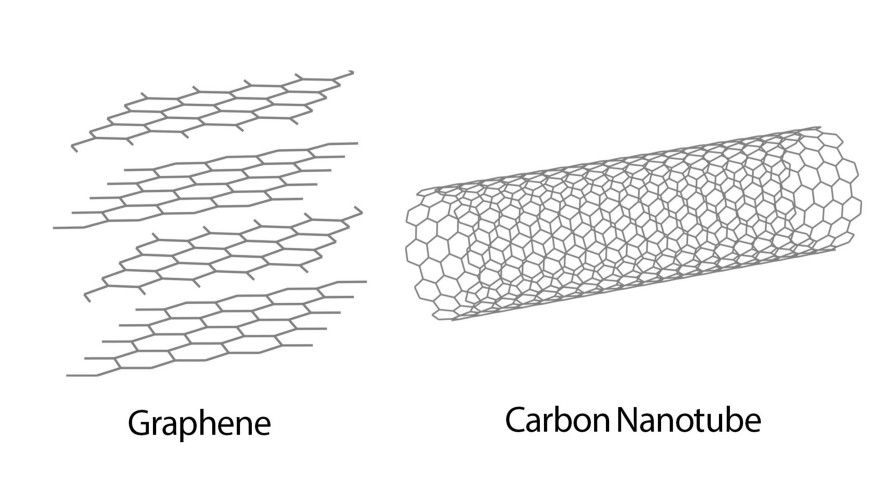

For current silicon-based technologies to categorize data from large sets like ECGs, it takes more than 100 transistors — each requiring its own energy to run. But Northwestern’s nanoelectronic device can perform the same machine-learning classification with just two devices. By reducing the number of devices, the researchers drastically reduced power consumption and developed a much smaller device that can be integrated into a standard wearable gadget.

The secret behind the novel device is its unprecedented tunability, which arises from a mix of materials. While traditional technologies use silicon, the researchers constructed the miniaturized transistors from two-dimensional molybdenum disulfide and one-dimensional carbon nanotubes. So instead of needing many silicon transistors — one for each step of data processing — the reconfigurable transistors are dynamic enough to switch among various steps.

“The integration of two disparate materials into one device allows us to strongly modulate the current flow with applied voltages, enabling dynamic reconfigurability,” Hersam said. “Having a high degree of tunability in a single device allows us to perform sophisticated classification algorithms with a small footprint and low energy consumption.”

To test the device, the researchers looked to publicly available medical datasets. They first trained the device to interpret data from ECGs, a task that typically requires significant time from trained health care workers. Then, they asked the device to classify six types of heart beats: normal, atrial premature beat, premature ventricular contraction, paced beat, left bundle branch block beat and right bundle branch block beat.

The nanoelectronic device was able to identify accurately each arrhythmia type out of 10,000 ECG samples. By bypassing the need to send data to the cloud, the device not only saves critical time for a patient but also protects privacy.

“Every time data are passed around, it increases the likelihood of the data being stolen,” Hersam said. “If personal health data is processed locally — such as on your wrist in your watch — that presents a much lower security risk. In this manner, our device improves privacy and reduces the risk of a breach.”

Hersam imagines that, eventually, these nanoelectronic devices could be incorporated into everyday wearables, personalized to each user’s health profile for real-time applications. They would enable people to make the most of the data they already collect without sapping power.

“Artificial intelligence tools are consuming an increasing fraction of the power grid,” Hersam said. “It is an unsustainable path if we continue relying on conventional computer hardware.”

…

Here’s a link to and a citation for the paper,

Reconfigurable mixed-kernel heterojunction transistors for personalized support vector machine classification by Xiaodong Yan, Justin H. Qian, Jiahui Ma, Aoyang Zhang, Stephanie E. Liu, Matthew P. Bland, Kevin J. Liu, Xuechun Wang, Vinod K. Sangwan, Han Wang & Mark C. Hersam. Nature Electronics (2023) DOI: https://doi.org/10.1038/s41928-023-01042-7 Published: 12 October 2023

This paper is behind a paywall.