A June 15, 2023 RMIT University (Australia) press release (also on EurekAlert but published June 14, 2023) announces a neuromorphic (brainlike) computer chip, which mimics human vision and ‘creates’ memories,

Researchers have created a small device that ‘sees’ and creates memories in a similar way to humans, in a promising step towards one day having applications that can make rapid, complex decisions such as in self-driving cars.

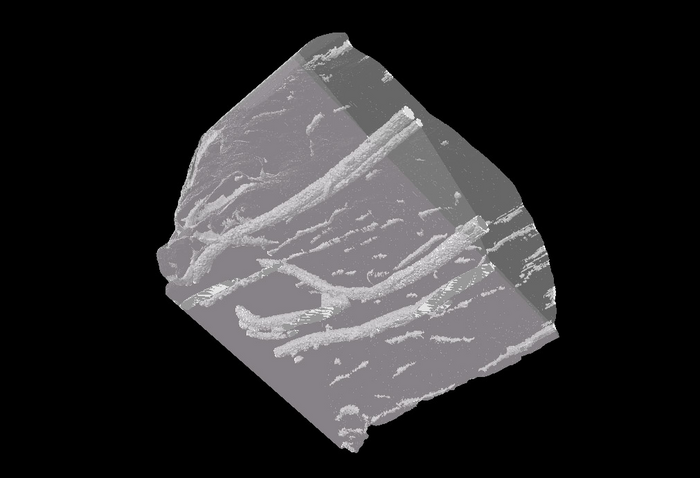

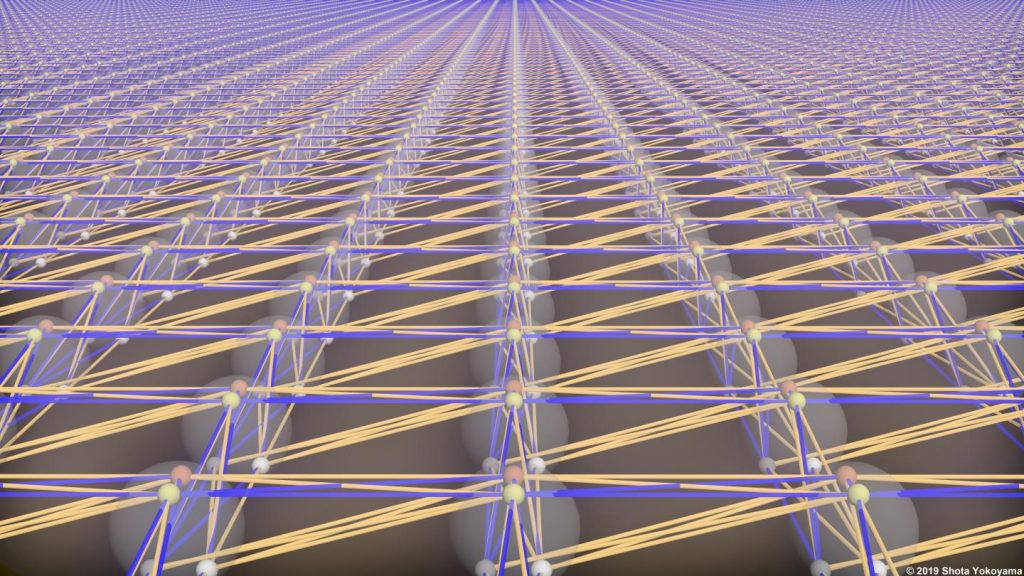

The neuromorphic invention is a single chip enabled by a sensing element, doped indium oxide, that’s thousands of times thinner than a human hair and requires no external parts to operate.

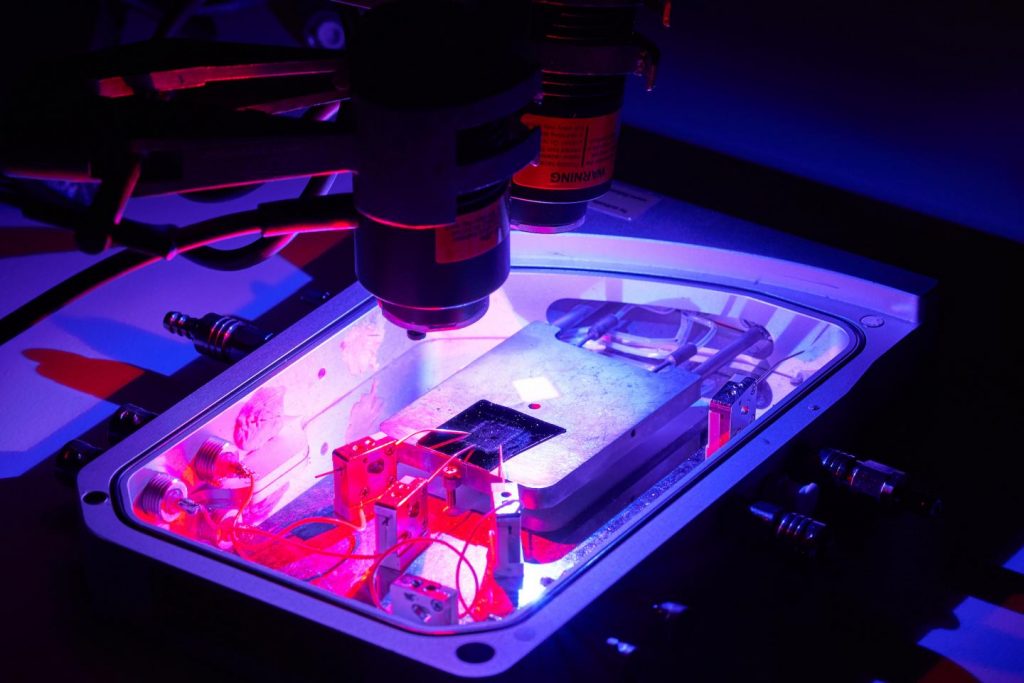

RMIT University engineers in Australia led the work, with contributions from researchers at Deakin University and the University of Melbourne.

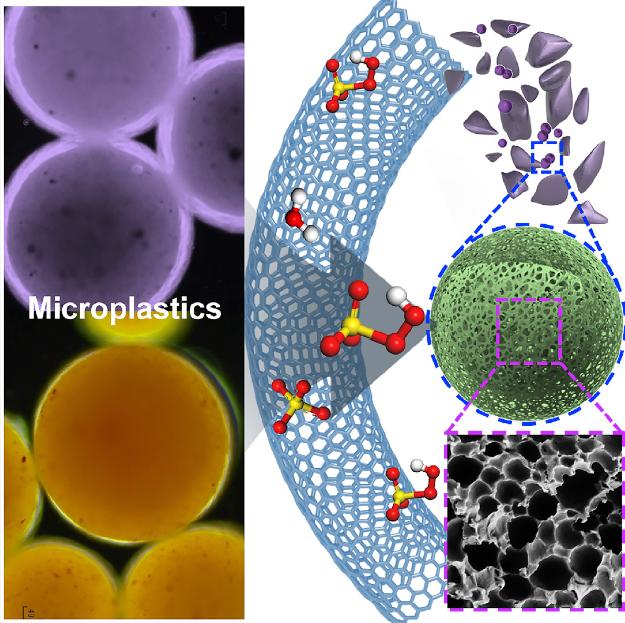

The team’s research demonstrates a working device that captures, processes and stores visual information. With precise engineering of the doped indium oxide, the device mimics a human eye’s ability to capture light, pre-packages and transmits information like an optical nerve, and stores and classifies it in a memory system like the way our brains can.

Collectively, these functions could enable ultra-fast decision making, the team says.

Team leader Professor Sumeet Walia said the new device can perform all necessary functions – sensing, creating and processing information, and retaining memories – rather than relying on external energy-intensive computation, which prevents real-time decision making.

“Performing all of these functions on one small device had proven to be a big challenge until now,” said Walia from RMIT’s School of Engineering.

“We’ve made real-time decision making a possibility with our invention, because it doesn’t need to process large amounts of irrelevant data and it’s not being slowed down by data transfer to separate processors.”

What did the team achieve and how does the technology work?

The new device was able to demonstrate an ability to retain information for longer periods of time, compared to previously reported devices, without the need for frequent electrical signals to refresh the memory. This ability significantly reduces energy consumption and enhances the device’s performance.

Their findings and analysis are published in Advanced Functional Materials.

First author and RMIT PhD researcher Aishani Mazumder said the human brain used analog processing, which allowed it to process information quickly and efficiently using minimal energy.

“By contrast, digital processing is energy and carbon intensive, and inhibits rapid information gathering and processing,” she said.

“Neuromorphic vision systems are designed to use similar analog processing to the human brain, which can greatly reduce the amount of energy needed to perform complex visual tasks compared with today’s technologies

What are the potential applications?

The team used ultraviolet light as part of their experiments, and are working to expand this technology even further for visible and infrared light – with many possible applications such as bionic vision, autonomous operations in dangerous environments, shelf-life assessments of food and advanced forensics.

“Imagine a self-driving car that can see and recognise objects on the road in the same way that a human driver can or being able to able to rapidly detect and track space junk. This would be possible with neuromorphic vision technology.”

Walia said neuromorphic systems could adapt to new situations over time, becoming more efficient with more experience.

“Traditional computer vision systems – which cannot be miniaturised like neuromorphic technology – are typically programmed with specific rules and can’t adapt as easily,” he said.

“Neuromorphic robots have the potential to run autonomously for long periods, in dangerous situations where workers are exposed to possible cave-ins, explosions and toxic air.”

The human eye has a single retina that captures an entire image, which is then processed by the brain to identify objects, colours and other visual features.

The team’s device mimicked the retina’s capabilities by using single-element image sensors that capture, store and process visual information on one platform, Walia said.

“The human eye is exceptionally adept at responding to changes in the surrounding environment in a faster and much more efficient way than cameras and computers currently can,” he said.

“Taking inspiration from the eye, we have been working for several years on creating a camera that possesses similar abilities, through the process of neuromorphic engineering.”

Here’s a link to and a citation for the paper,

Long Duration Persistent Photocurrent in 3 nm Thin Doped Indium Oxide for Integrated Light Sensing and In-Sensor Neuromorphic Computation by Aishani Mazumder, Chung Kim Nguyen, Thiha Aung, Mei Xian Low, Md. Ataur Rahman, Salvy P. Russo, Sherif Abdulkader Tawfik, Shifan Wang, James Bullock, Vaishnavi Krishnamurthi. Advanced Functional Materials DOI: https://doi.org/10.1002/adfm.202303641 First published: 14 June 2023

This paper is open access.