As i best I can determine ,the last mention of a self-powered pacemaker and the like on this blog was in a Nov. 5, 2012 posting (Developing self-powered batteries for pacemakers). This latest news from The Korea Advanced Institute of Science and Technology (KAIST) is, I believe, the first time that such a device has been successfully tested in vivo. From a June 23, 2014 news item on ScienceDaily,

As the number of pacemakers implanted each year reaches into the millions worldwide, improving the lifespan of pacemaker batteries has been of great concern for developers and manufacturers. Currently, pacemaker batteries last seven years on average, requiring frequent replacements, which may pose patients to a potential risk involved in medical procedures.

A research team from the Korea Advanced Institute of Science and Technology (KAIST), headed by Professor Keon Jae Lee of the Department of Materials Science and Engineering at KAIST and Professor Boyoung Joung, M.D. of the Division of Cardiology at Severance Hospital of Yonsei University, has developed a self-powered artificial cardiac pacemaker that is operated semi-permanently by a flexible piezoelectric nanogenerator.

A June 23, 2014 KAIST news release on EurekAlert, which originated the news item, provides more details,

The artificial cardiac pacemaker is widely acknowledged as medical equipment that is integrated into the human body to regulate the heartbeats through electrical stimulation to contract the cardiac muscles of people who suffer from arrhythmia. However, repeated surgeries to replace pacemaker batteries have exposed elderly patients to health risks such as infections or severe bleeding during operations.

The team’s newly designed flexible piezoelectric nanogenerator directly stimulated a living rat’s heart using electrical energy converted from the small body movements of the rat. This technology could facilitate the use of self-powered flexible energy harvesters, not only prolonging the lifetime of cardiac pacemakers but also realizing real-time heart monitoring.

The research team fabricated high-performance flexible nanogenerators utilizing a bulk single-crystal PMN-PT thin film (iBULe Photonics). The harvested energy reached up to 8.2 V and 0.22 mA by bending and pushing motions, which were high enough values to directly stimulate the rat’s heart.

Professor Keon Jae Lee said:

“For clinical purposes, the current achievement will benefit the development of self-powered cardiac pacemakers as well as prevent heart attacks via the real-time diagnosis of heart arrhythmia. In addition, the flexible piezoelectric nanogenerator could also be utilized as an electrical source for various implantable medical devices.”

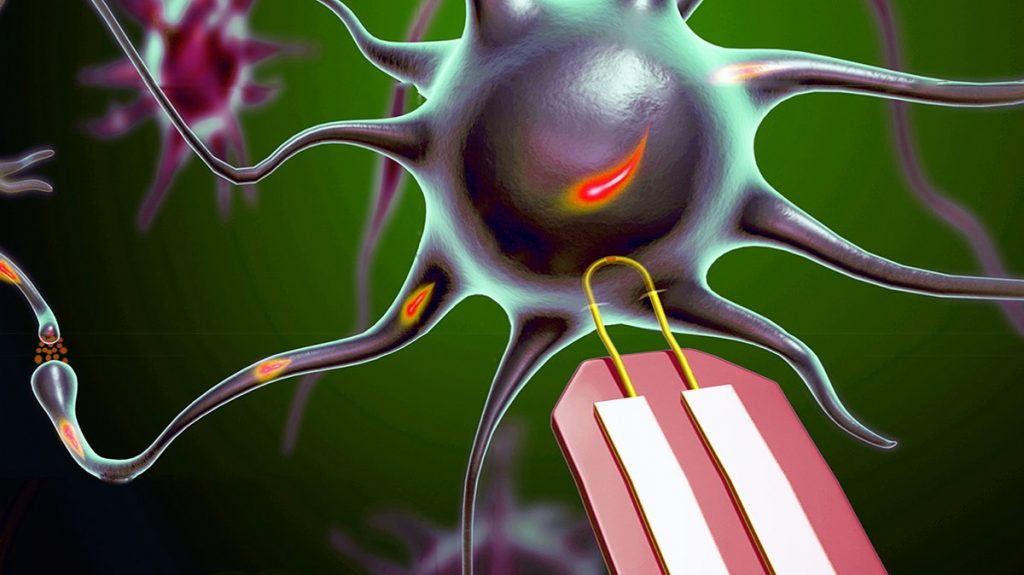

This image illustrating a self-powered nanogenerator for a cardiac pacemaker has been provided by KAIST,

This picture shows that a self-powered cardiac pacemaker is enabled by a flexible piezoelectric energy harvester.

Credit: KAIST

Here’s a link to and a citation for the paper,

Self-Powered Cardiac Pacemaker Enabled by Flexible Single Crystalline PMN-PT Piezoelectric Energy Harvester by Geon-Tae Hwang, Hyewon Park, Jeong-Ho Lee, SeKwon Oh, Kwi-Il Park, Myunghwan Byun, Hyelim Park, Gun Ahn, Chang Kyu Jeong, Kwangsoo No, HyukSang Kwon, Sang-Goo Lee, Boyoung Joung, and Keon Jae Lee. Advanced Materials DOI: 10.1002/adma.201400562

Article first published online: 17 APR 2014

© 2014 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

This paper is behind a paywall.

There was a May 15, 2014 KAIST news release on EurekAlert announcing this same piece of research but from a technical perspective,

The energy efficiency of KAIST’s piezoelectric nanogenerator has increased by almost 40 times, one step closer toward the commercialization of flexible energy harvesters that can supply power infinitely to wearable, implantable electronic devices

NANOGENERATORS are innovative self-powered energy harvesters that convert kinetic energy created from vibrational and mechanical sources into electrical power, removing the need of external circuits or batteries for electronic devices. This innovation is vital in realizing sustainable energy generation in isolated, inaccessible, or indoor environments and even in the human body.

Nanogenerators, a flexible and lightweight energy harvester on a plastic substrate, can scavenge energy from the extremely tiny movements of natural resources and human body such as wind, water flow, heartbeats, and diaphragm and respiration activities to generate electrical signals. The generators are not only self-powered, flexible devices but also can provide permanent power sources to implantable biomedical devices, including cardiac pacemakers and deep brain stimulators.

However, poor energy efficiency and a complex fabrication process have posed challenges to the commercialization of nanogenerators. Keon Jae Lee, Associate Professor of Materials Science and Engineering at KAIST, and his colleagues have recently proposed a solution by developing a robust technique to transfer a high-quality piezoelectric thin film from bulk sapphire substrates to plastic substrates using laser lift-off (LLO).

Applying the inorganic-based laser lift-off (LLO) process, the research team produced a large-area PZT thin film nanogenerators on flexible substrates (2 cm x 2 cm).

“We were able to convert a high-output performance of ~250 V from the slight mechanical deformation of a single thin plastic substrate. Such output power is just enough to turn on 100 LED lights,” Keon Jae Lee explained.

The self-powered nanogenerators can also work with finger and foot motions. For example, under the irregular and slight bending motions of a human finger, the measured current signals had a high electric power of ~8.7 μA. In addition, the piezoelectric nanogenerator has world-record power conversion efficiency, almost 40 times higher than previously reported similar research results, solving the drawbacks related to the fabrication complexity and low energy efficiency.

Lee further commented,

“Building on this concept, it is highly expected that tiny mechanical motions, including human body movements of muscle contraction and relaxation, can be readily converted into electrical energy and, furthermore, acted as eternal power sources.”

The research team is currently studying a method to build three-dimensional stacking of flexible piezoelectric thin films to enhance output power, as well as conducting a clinical experiment with a flexible nanogenerator.

In addition to the 2012 posting I mentioned earlier, there was also this July 12, 2010 posting which described research on harvesting biomechanical movement ( heart beat, blood flow, muscle stretching, or even irregular vibration) at the Georgia (US) Institute of Technology where the lead researcher observed,

… Wang [Professor Zhong Lin Wang at Georgia Tech] tells Nanowerk. “However, the applications of the nanogenerators under in vivo and in vitro environments are distinct. Some crucial problems need to be addressed before using these devices in the human body, such as biocompatibility and toxicity.”

Bravo to the KAIST researchers for getting this research to the in vivo testing stage.

Meanwhile at the University of Bristol and at the University of Bath, researchers have received funding for a new approach to cardiac pacemakers, designed them with the breath in mind. From a June 24, 2014 news item on Azonano,

Pacemaker research from the Universities of Bath and Bristol could revolutionise the lives of over 750,000 people who live with heart failure in the UK.

The British Heart Foundation (BHF) is awarding funding to researchers developing a new type of heart pacemaker that modulates its pulses to match breathing rates.

A June 23, 2014 University of Bristol press release, which originated the news item, provides some context,

During 2012-13 in England, more than 40,000 patients had a pacemaker fitted.

Currently, the pulses from pacemakers are set at a constant rate when fitted which doesn’t replicate the natural beating of the human heart.

The normal healthy variation in heart rate during breathing is lost in cardiovascular disease and is an indicator for sleep apnoea, cardiac arrhythmia, hypertension, heart failure and sudden cardiac death.

The device is then briefly described (from the press release),

The novel device being developed by scientists at the Universities of Bath and Bristol uses synthetic neural technology to restore this natural variation of heart rate with lung inflation, and is targeted towards patients with heart failure.

The device works by saving the heart energy, improving its pumping efficiency and enhancing blood flow to the heart muscle itself. Pre-clinical trials suggest the device gives a 25 per cent increase in the pumping ability, which is expected to extend the life of patients with heart failure.

One aim of the project is to miniaturise the pacemaker device to the size of a postage stamp and to develop an implant that could be used in humans within five years.

Dr Alain Nogaret, Senior Lecturer in Physics at the University of Bath, explained: “This is a multidisciplinary project with strong translational value. By combining fundamental science and nanotechnology we will be able to deliver a unique treatment for heart failure which is not currently addressed by mainstream cardiac rhythm management devices.”

The research team has already patented the technology and is working with NHS consultants at the Bristol Heart Institute, the University of California at San Diego and the University of Auckland. [emphasis mine]

Professor Julian Paton, from the University of Bristol, added: “We’ve known for almost 80 years that the heart beat is modulated by breathing but we have never fully understood the benefits this brings. The generous new funding from the BHF will allow us to reinstate this natural occurring synchrony between heart rate and breathing and understand how it brings therapy to hearts that are failing.”

Professor Jeremy Pearson, Associate Medical Director at the BHF, said: “This study is a novel and exciting first step towards a new generation of smarter pacemakers. More and more people are living with heart failure so our funding in this area is crucial. The work from this innovative research team could have a real impact on heart failure patients’ lives in the future.”

Given some current events (‘Tesla opens up its patents’, Mike Masnick’s June 12, 2014 posting on Techdirt), I wonder what the situation will be vis à vis patents by the time this device gets to market.

* ‘one’ added to title on Aug. 13, 2014.