The US National Aeronautics and Space Administration (NASA) has made an open call for art works that could be part of the the Origins, Spectral Interpretation, Resource Identification, Security-Regolith Explorer (OSIRIS-REx) spacecraft mission bound for Bennu (an asteroid). From a Feb. 23, 2016 NASA news release on EurekAlert,

OSIRIS-REx is scheduled to launch in September and travel to the asteroid Bennu. The #WeTheExplorers campaign invites the public to take part in this mission by expressing, through art, how the mission’s spirit of exploration is reflected in their own lives. Submitted works of art will be saved on a chip on the spacecraft. The spacecraft already carries a chip with more than 442,000 names submitted through the 2014 “Messages to Bennu” campaign.

“The development of the spacecraft and instruments has been a hugely creative process, where ultimately the canvas is the machined metal and composites preparing for launch in September,” said Jason Dworkin, OSIRIS-REx project scientist at NASA’s Goddard Space Flight Center in Greenbelt, Maryland. “It is fitting that this endeavor can inspire the public to express their creativity to be carried by OSIRIS-REx into space.”

A submission may take the form of a sketch, photograph, graphic, poem, song, short video or other creative or artistic expression that reflects what it means to be an explorer. Submissions will be accepted via Twitter and Instagram until March 20, 2016. For details on how to include your submission on the mission to Bennu, go to:

http://www.

asteroidmission. org/ WeTheExplorers “Space exploration is an inherently creative activity,” said Dante Lauretta, principal investigator for OSIRIS-REx at the University of Arizona, Tucson. “We are inviting the world to join us on this great adventure by placing their art work on the OSIRIS-REx spacecraft, where it will stay in space for millennia.”

The spacecraft will voyage to the near-Earth asteroid Bennu to collect a sample of at least 60 grams (2.1 ounces) and return it to Earth for study. Scientists expect Bennu may hold clues to the origin of the solar system and the source of the water and organic molecules that may have made their way to Earth.

Goddard provides overall mission management, systems engineering and safety and mission assurance for OSIRIS-REx. The University of Arizona, Tucson leads the science team and observation planning and processing. Lockheed Martin Space Systems in Denver is building the spacecraft. OSIRIS-REx is the third mission in NASA’s New Frontiers Program. NASA’s Marshall Space Flight Center in Huntsville, Alabama, manages New Frontiers for the agency’s Science Mission Directorate in Washington.

I wonder why the Egyptian mythology as in Osiris and Bennu. For those who need a refresher on the topic, here’s more from the Osiris entry on Wikipedia (Note: Links have been removed),

Osiris (/oʊˈsaɪərᵻs/, alternatively Ausir, Asiri or Ausar, among other spellings), was an Egyptian god, usually identified as the god of the afterlife, the underworld, and the dead, but more appropriately as the god of transition, resurrection, and regeneration.

Then there’s this from the Bennu entry on Wikipedia (Note: Links have been removed),

The Bennu is an ancient Egyptian deity linked with the sun, creation, and rebirth. It may have been the inspiration for the phoenix in Greek mythology.

You can find out more about Bennu, the asteriod, on its webpage, The long Strange Trip of Bennu on the NASA website (which also features a video animation), Note: A link has been removed,

… Born from the rubble of a violent collision, hurled through space for millions of years and dismembered by the gravity of planets, asteroid Bennu had a tough life in a rough neighborhood: the early solar system. …

“We are going to Bennu because we want to know what it has witnessed over the course of its evolution,” said Edward Beshore of the University of Arizona, Deputy Principal Investigator for NASA’s asteroid-sample-return mission OSIRIS-REx (Origins, Spectral Interpretation, Resource Identification, Security – Regolith Explorer). The mission will be launched toward Bennu in late 2016, arrive at the asteroid in 2018, and return a sample of Bennu’s surface to Earth in 2023.

“Bennu’s experiences will tell us more about where our solar system came from and how it evolved. Like the detectives in a crime show episode, we’ll examine bits of evidence from Bennu to understand more completely the story of the solar system, which is ultimately the story of our origin.”

As for the spacecraft, you can find out more about OSIRIS-REx here.

Getting back to the artwork, Sarah Cascone has written a Feb. 22, 2016 posting for artnet news, which features the call for submissions and some work which already been submitted (Note: Links have been removed),

The near-Earth asteroid Bennu will become the first extra-terrestrial art gallery, with the space agency inviting the public to contribute works of art that are inspired by the spirit of exploration.

The project will follow other important moments in space art history, which include work by Invader traveling aboard the International Space Station, conceptual artwork on the UKube-1 satellite, and even a bonsai tree launched into space.

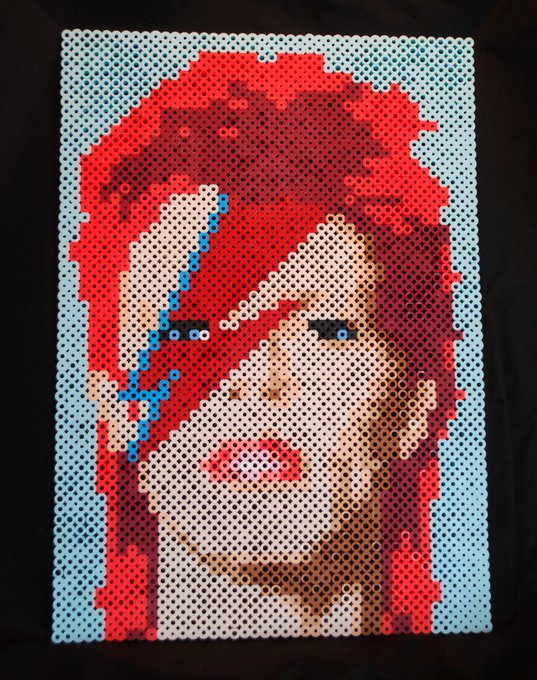

Here’s a selection of the artworks being embedded in Cascone’s posting,

Daughter’s #Bowie is spacebound! Fitting tribute to a pioneering, star-loving musician @OSIRISREx#WeTheExplorers

For more inspiration, check out Cascone’s Feb. 22, 2016 posting.

Good luck!